Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

YMP was established in 2004. Our factory is located at Shajing Road 211-3, Shatou Industrial Park, Shajing Street, Bao'an Distrist, Shenzhen(518104), China.

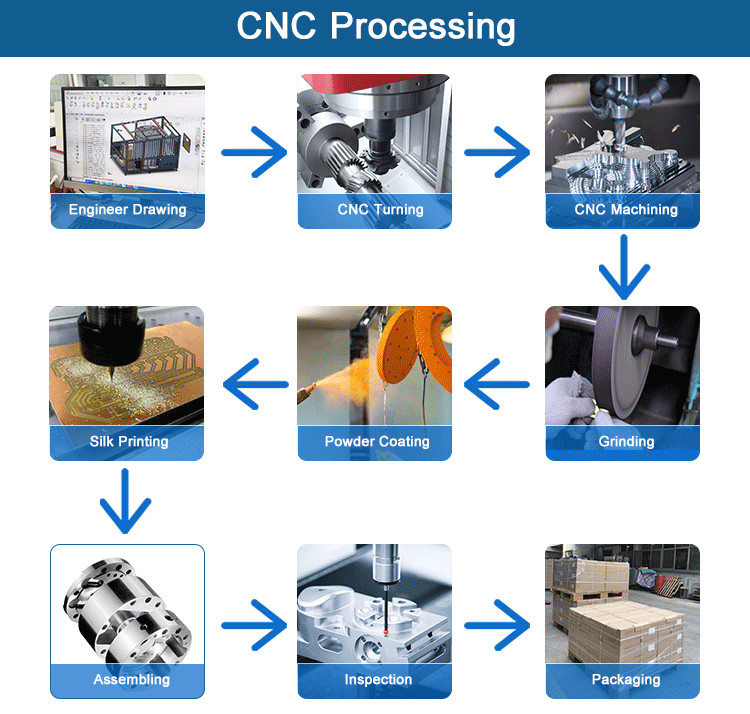

A manufacturer that provides comprehensive hardware accessories technical services. At present, there are more than 130 sets of supporting equipment such as CNC lathes and punching machines.

The main processed products are: hardware accessories, shafts, bolts, lathe parts, stamping parts, connectors, fasteners, hardware car parts, non-standard parts, etc.Specification. The main raw materials of the product: brass, iron, aluminum, stainless steel, etc.

YMP always provides customers with a full range of services. We provide customers with comprehensive technical consultation, produce suitable products according to customer needs, and formulate reasonable plans.

Quality is our lifeline. We always implement "continuous improvement" "Product quality, always meet customer needs" quality policy. Customers at home and abroad are welcome to visit and negotiate cooperation projects. If you have any needs or questions, please feel free to contact us.

The principle of blackening, also called bluing, is to immerse the product in a strong oxidizing chemical solution to produce an oxide film on the metal surface to isolate the air and achieve the purpose of rust prevention.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

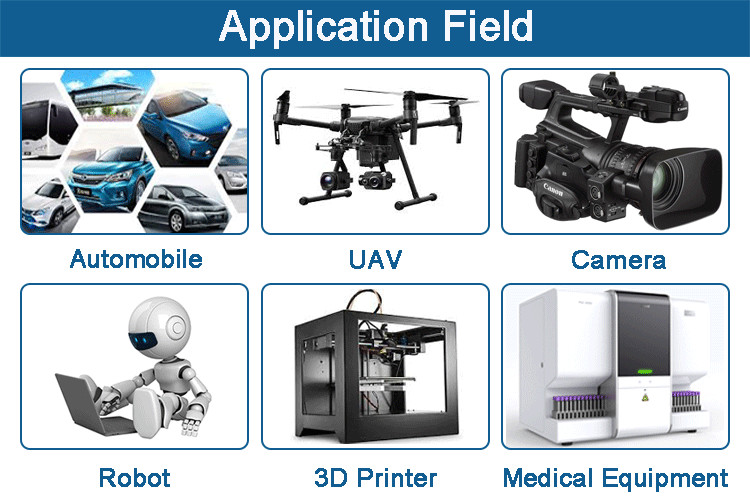

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

1) Inquiry--provide us with all clear requirements (total qty and package details).

2) Quotation--an official quotation form with all clear specifications from our professional team.

3) Marking Sample--confirm all quotation details and the final sample.

4) Production--mass production.

5) Shipping--by sea or by air.

As for the payment terms, it depends on the total amount.

By Sea, By Air, By courier, TNT, DHL, FedEx, UPS Etc. It is up to you.

Sample usually takes about 10-20days depending on product type. Bulk order usually takes about 35 days.

Please e-mail us, and tell us about your market with MOQ for each order. We would send the competitive price list to you ASAP.