Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

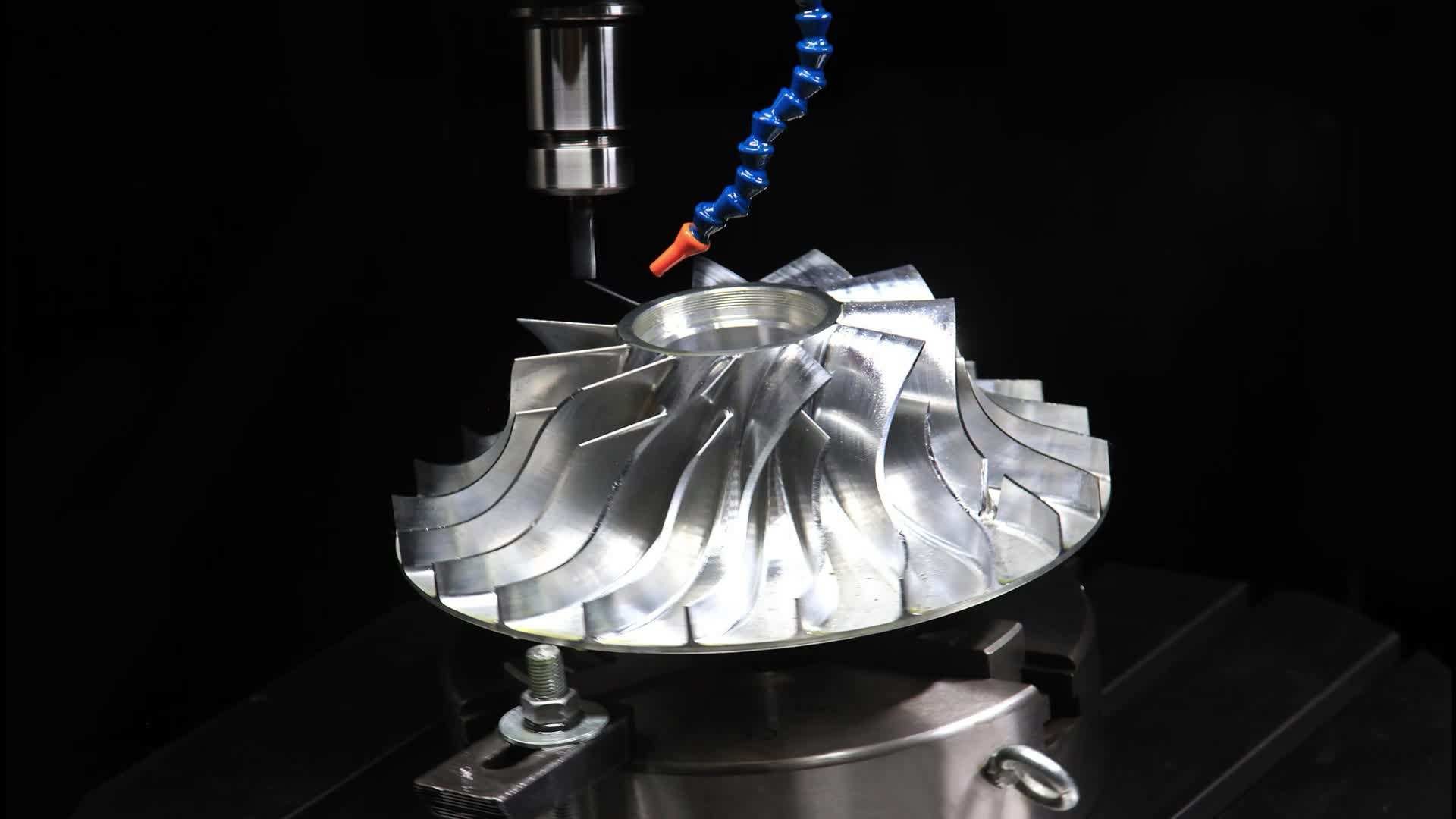

YMP was founded in 2004, We have accumulated rich experience, inherits the advanced industrial concept and owned professional design team and First-class equipments. We also through ISO, SGS certifications. We dedicates to the precision Metal stamping, CNC machining and the production of sheet metal parts.

Focusing on processing with all kinds of materials like aluminum, steel, stainless steel, brass, and plastic etc. We also make various surface treatment like Anodizing, Plating, Painting, Brushed, Deactivation, Polishing, Grinding, Silk-screen, Laser Carving etc.

YMP finished all the processing procedure From the drawings design to mold production to blank to surface treatment. We provide one-stop service for customers, which will greatly reduce the customer′s cost about product development and the purchasing.

Our company has the right in import and export by itself, Our products are based on Mainland China, and we are actively developing foreign markets.

YMP will create the most satisfying value for customers with superior technology, advanced concept and Chinese manufacturing.

CNC Machining or Not | CNC Machining |

Type | metal:aluminum: 2024,5052,6061,6063,6082,7075 etc. Steel: carbon steel (No.10,15,20,25,30,35,40,45...80). etc. alloy steel (15Cr,20Cr,42CrMo) and other etc. Stainless steel: 201,202,301,302,303,304,316,317,420,430,440,630 etc. Brass, copper, bronze:H62,H65.H90,HA177-2,HPb59-1, HSn70-1 etc. Titanium:TA1,TA2,TA3,TA4,TA5,TC1,TC2,TC3,TC4,TC5 etc. |

Material Capabilities | Aluminum, Brass, Bronze, Copper, Hardened Metals, Precious Metals,

Stainless Steel, Steel Alloys |

Micro Machining or Not | Micro Machining |

Process | CNC machining Service |

Material | Brass/Aluminum/hardened metals/stainless steel/carbon steel |

Finishing | Sanding/ Polishing/Painting/electroplating/Nickel

plated/Painting/powder coating/anodized etc+/-0.002mm |

Tolerance | +/-0.002mm |

Quality | 100% QC Test before shipment |

CE or ISO | passed |

Color | customized |

What is the difference between powder coating and painting?

> > Powder coating for dusting does not contain any solvent, which is environmentally friendly and pollution-free, while paint contains solvent.

> > The utilization rate of powder coating is high, about over 95%, and the painted coating can only be kept for a short time.

> > There are many kinds of paints and relatively few kinds of powder spraying.

> > Powder coating is thicker than paint coating, and the surface effect of paint coating is smoother than that of powder coating.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.

A: There are some basic specs we need to know for price calculation, that are:3D drawings in STP, IGS, and X-T format are available, Please suggest to us your quantity too.

A: We are a factory.

A: Yes! We are always happy to work with potential customers to evaluate the technical feasibility of your idea or design and we can advise on materials tooling and likely set-up costs.

A: Mould tools can be either single impression (one part at a time)or multi-impression(2, 4, 8, or 16 parts at a time). Single impression tools are generally used for small quantities, up to 10,000 parts per year whereas multi-impression tools are for larger quantities. We can look at your projected annual requirements and recommend which would be best for you.

A: It will take 3-8 weeks to have the tooling manufactured which depends on the part's complexity and the number of impressions(single or multi). After the tooling is completed, you can expect delivery of trial shot samples within 2-3 days.