Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

Hot Selling Front Axle Right Tie Rod End Auto Spare Parts High Quality Customized Auto Steering Spare Parts Tie Rod End

>>The Parameters of Product:

| Item | Value |

| CNC Machining or Not | Cnc Machining |

| Type | DRILLING, Etching Machining, Laser Machining, Milling, Chemical Machining, Turning, Wire EDM, Rapid Prototyping, Other Machining Services |

| Material Capabilities | Aluminum alloy, Brass, Magnesium alloy, Stainless Steel, Steel Alloys and so on |

| Micro Machining or Not | Micro Machining |

| Process | Cnc machining Service |

| Material | Aluminum alloy,Magnesium alloy |

| Finishing | Nickel plated/Painting/powder coating/anodized etc+/- 0.005mm |

| Tolerance | ±0.005mm |

| Main market | USA,European/UK/Japan/Canada/Australia etc |

| Quality | 100% QC Test before shipment |

| Quality Assurance | TS16949, ISO9001:2015 Certified, SGS Certification |

| Color | Customized |

| Size | Customized |

| Surface Treatment | Chrome Plating, ZincPlating, Nickel plating, Electrophoresis, Anodization, Polishing, Powder coating, Sandblasting, Passivation, Spray painting, Etc. |

| Mainly Testing Facility | Three-dimensional measuring instrument (CMM), Salt spray test box, Dynamic balance detector, Pneumatic detection. |

>>Our Processing:

>>The Applications:

①3D Printer; ②Auto Parts; ③Medical Equipment; ④Computer Case; ⑤Smart Camera; ⑤Electrical machinery; ⑤Audio equipment; and so on

>>About US:

Shenzhen Yixin Precision Metal and Plastic Ltd. is a one-stop service factory specializing in aluminum machining, anodizing and assembling. The company was established in 2004 and has long been devoted to the production of aluminum products for any industry.

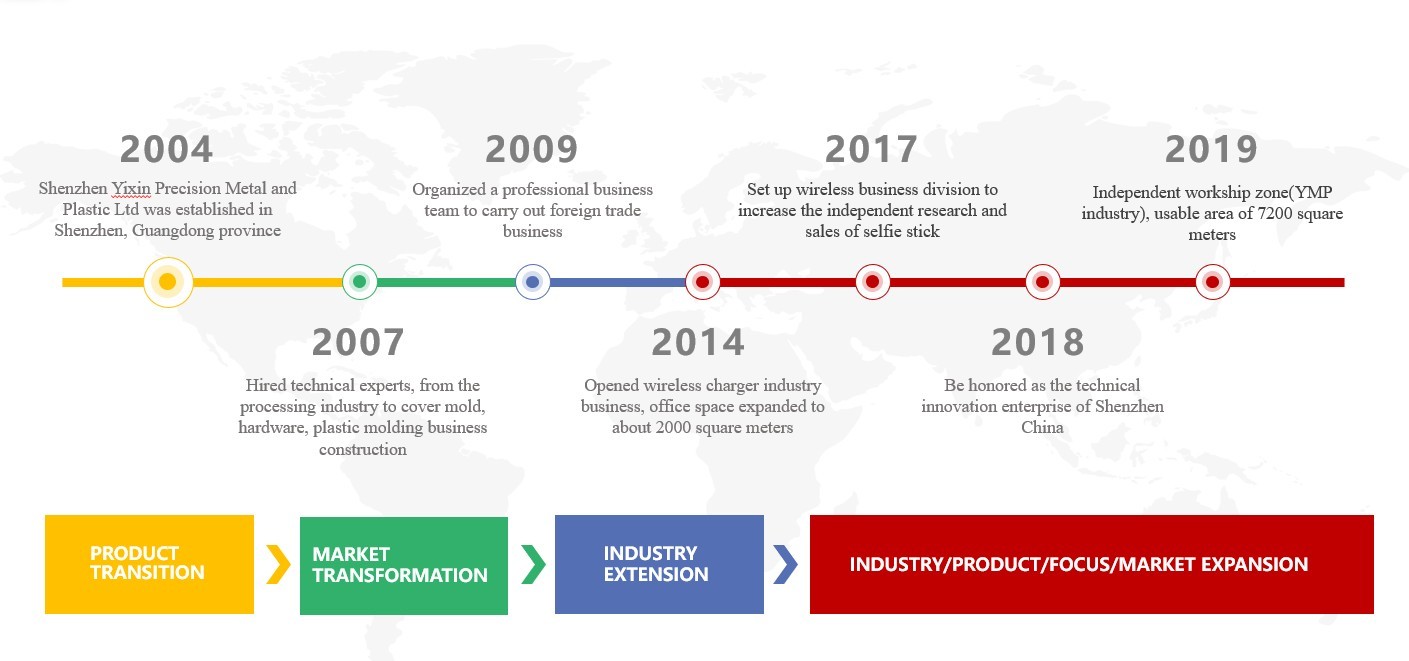

>>The Development of Company:

>>Our service

The specialist provides 24h service for customer; the engineers

spent a lot of time studying the impact of different aluminum

elements and different oxidation of the pigment on the anode, in

the appearance of high demand aluminum machining has its own unique

advantages.

1. Over 20 years factory.

2. MOQ is unlimited quantity.

3. Copy the second set of mould free of charge.

4. Standard:ISO9001:2015.100% inspection.

5. The National High-tech Enterprises.

6. 21 utility model patents and 2 invention patents.

7. Provide custom service. Accept OEM and ODM.

8. Delivery on time. Annual output reached 2500 tons.

>>Our Machining Equipments:

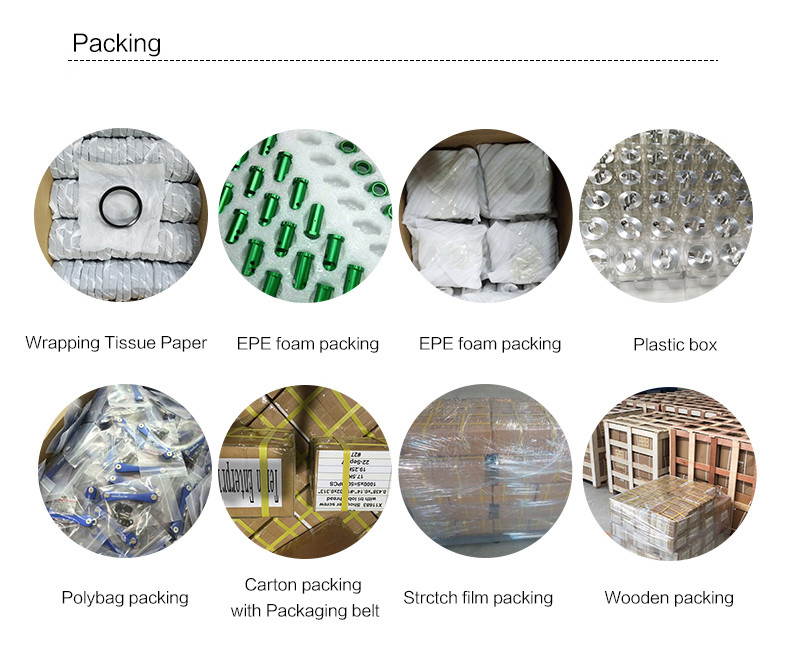

>>Packaging:

>>More Related Products: