Active Member

|

[China]

Address: Shajing Road 211-3, Shatou Industrial Park, Shajing Street, Bao'an Distrist, Shenzhen(518104), China

Contact name:William Zhang

Shenzhen Yi Xin Precision Metal And Plastic Ltd |

|

| Design: | Auto CAD, Pro/E, Solidworks, UG (dwg, dxf, IGS, STP, X-T) |

| Manufacture: | We use With advanced technology, unmatched skill, professional and advanced equipment size range from 15T-160T, and experienced technicians to fit our customers requirements, like tooling manufacturing, stamping and surface treatment service |

| Mould Cavity/core material: | DIN1.2344, 738H, 718, 8407, S136, NAK80,P20, SKD-61, NIMAX etc |

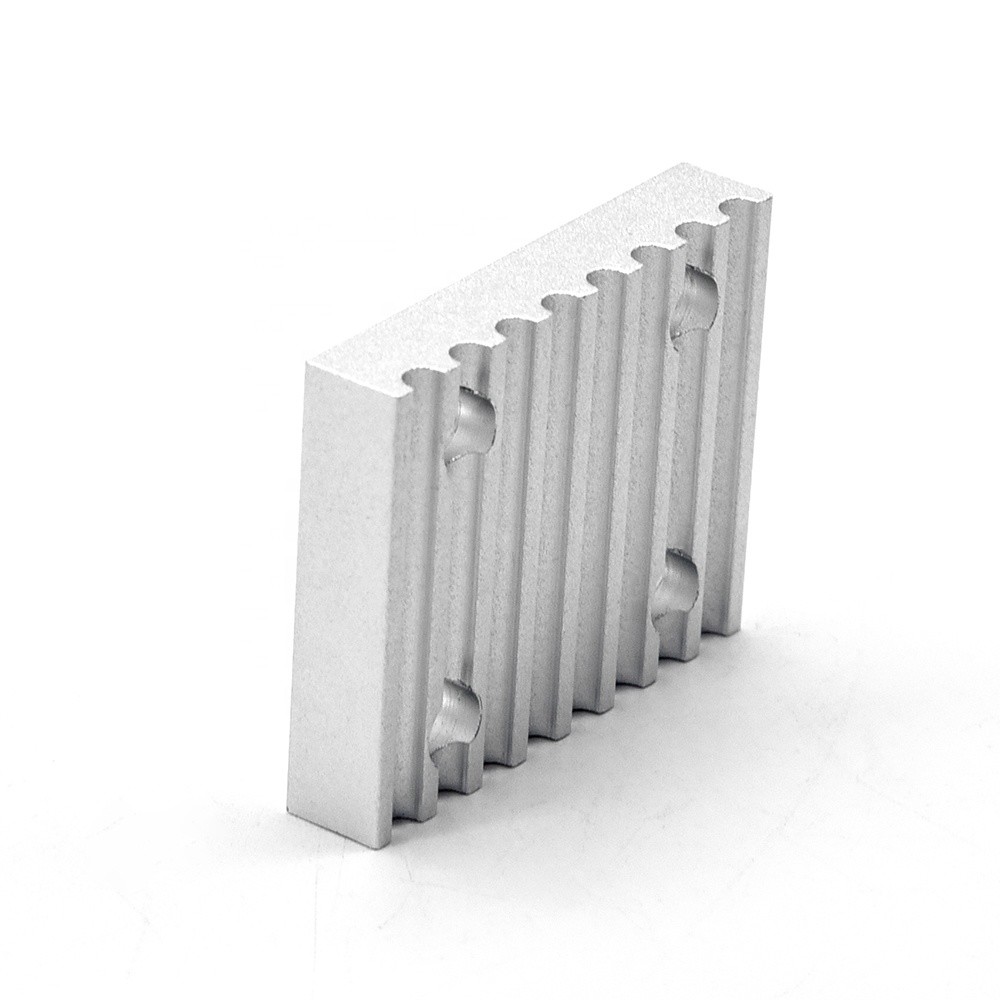

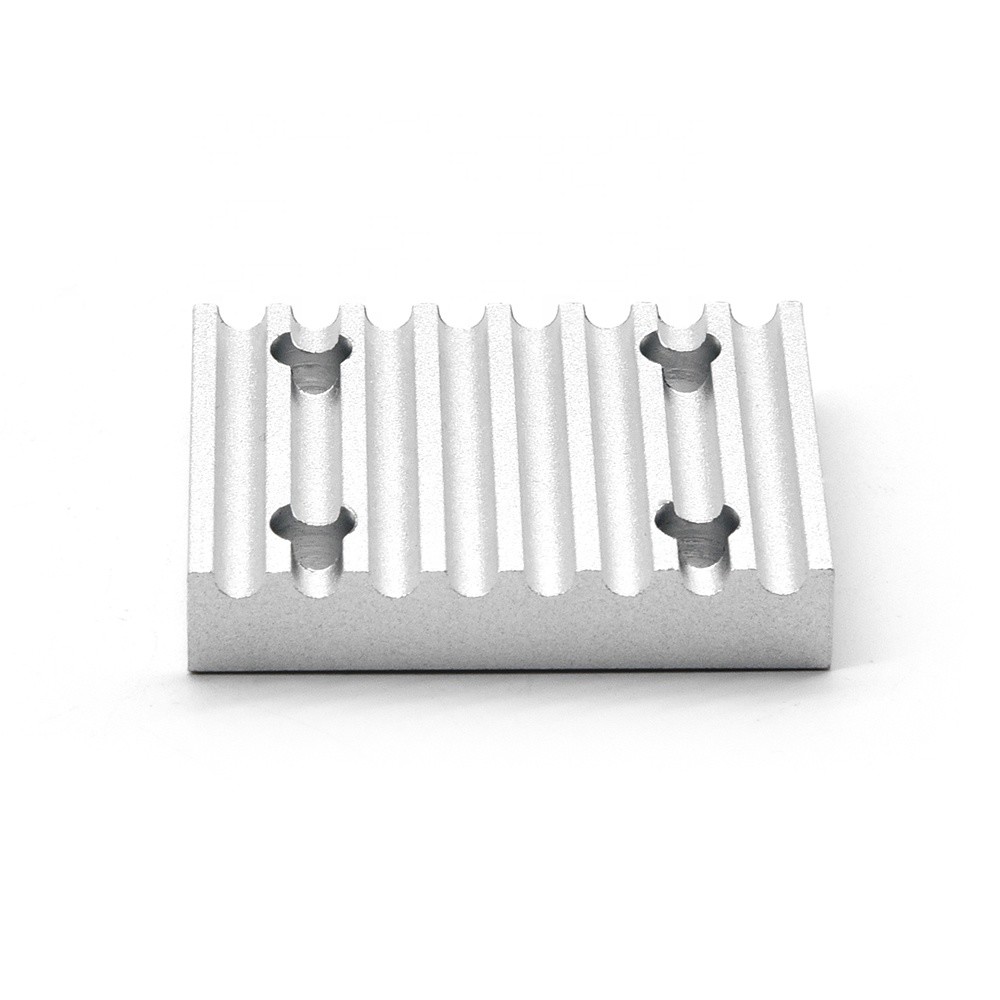

| Product Material: | Stainless steel, carbon steel, aluminum, brass, Aluminum alloy, and so on |

| Making process: | Progression die, Stamping, deep drawing, Bending, Punching, Threading, Welding, Tapping, Riveting, Grinding, CNC machining, Forging, Casting, Broaching,etc. |

| Product Surface treatment: | Anodizing, Powder-Coating, Zinc-Plated, Chrome coated,Nickel Plated,Hex Chromates Zinc, Rust-inhibiting oils, Electrophoresis, Paints and primers, blacking, etc |

| Heat treatment capability | Annealing, Normalizing, Nitriding, Tempering,Carbonitriding, Carburizing and induction hardening |

| Processing machine | CNC machines, Automatic lathe machine, Stamping Lathes, Milling/ Grinding machine, Drilling/ Boring/ Honing machine,Ultrasonic cleaning machine and other advanced production equipments. |

| Tolerance | 0.02mm |

| Lead time: | 25-50days based on the different products |

| Packaging: | canton case or as per customers’ requirement |

| Certification: | ISO9001:2008 |

| Application | Automotive, Electrical, Building, Furniture, Household, Machine assembly, Computer, Air industry. OEM/ODM Electronics |

Polishing is to make the product beautiful, transparent and protect the surface. Polishing transparency is your very good choice. Hardware polishing can be divided into manual polishing, mechanical polishing and electrolytic polishing. Electrolytic polishing can be used to replace heavy mechanical polishing, especially for parts with complicated shapes and parts that are difficult to be machined by manual polishing and mechanical methods. Electrolytic polishing is often used for steel, aluminum, copper and other parts.

Most CNC factories only focus on CNC machining, but are not good at surface treatment. If the surface treatment of parts does not meet expectations, it will not only increase the cost, but also affect the time to market of products.

YMP has rich experience in surface treatment of metal parts, and we will choose suitable surface treatment process according to different parts materials and uses.

The common surface treatments of YMP include: electroplating, electrophoresis, painting, powder spraying, sand blasting, polishing, shot blasting, laser engraving, etching, CD pattern, silk screen printing, wire drawing, blackening, anodizing, hard oxidation, thick film oxidation, micro-arc oxidation and so on. No matter what personalized requirements your parts need, we can meet them.

There are various parts that can be processed by CNC, involving a wide range of industries.

YMP has many years of experience in making OEM parts, and there are 475 kinds of materials. Basically, we can process all the metal materials in the market, and we are equipped with spectrometers to ensure the authenticity of the materials. So you don't have to worry about material problems when you choose YMP. We have stocks of aluminum alloy, stainless steel, magnesium alloy, titanium alloy, zinc alloy, nickel alloy, copper, steel, and so on.