Shenzhen Honreal Technology Co.,Ltd |

|

Verified Suppliers

|

|

Smd Soldering Machine Pcb Soldering Oven Smt Reflow Soldering Machine

Product introduction:

Machine's parameters:

| Model | HRM-840 |

| Heating zones | Upper 8 zones |

Bottom 8 zones

| |

| Heating tunnel | 2673mm |

| Dimension | L4600*W1200*H1450 |

| Net weight | about 1300Kg |

| General power | 53KW |

| Power consumption | Approx.5--9KW |

| Ramp Time from Room Temperature to 260 Deg C | < 20 mins |

| Controlling type | Touch screen and PLC |

| Heating method | Fully forced air convection |

| Temperature controlling | PID close-loop control, SSR drive |

| Temperature range | Ambient---350℃ |

| Temperature accurancy | ±1 ℃ |

| Temperature uniform | ±2 ℃ |

| Cooling | Two cooling zones,industrial chiller for cooling |

| Conveyor method | Mesh belt and chain conveyor |

| Conveyor height | 900±20mm |

| Mesh belt width | 450mm |

| Max PCB width | 400mm |

| Width adjustment | Manual |

| PCB clearance | 30mm |

| Conveyor direction | Left to right |

| Conveyor speed | 200-1000mm/min |

| Hook lift | Electrical screw pole |

| Power supply | 380v,3ph,50hz |

HRE-840 Lead Free Reflow Oven Aluminum Heating System

Aluminum heating system is made up by 2 pieces aluminum plates (topand bottom) and 2 pieces U shape heater by stainless steel, comparewith the traditional heater, advantages as below:

1.Easy to replace and maintain, only need to remove fix screws andreplace U-heater.

2.lt has longer service life than old version, can save more cost forcustomers.

3.Better raw materials to ensure the stability of oven temperature.

4.Customers can replace aluminum heating system on installed reflowovens(with old heating elements), maintenance and service problem canbe solved at once.

HRE-840 Lead Free Reflow Oven Controlling System

1.Full English interface, easy to be operated which can stock more than 50groups parameters with recommended leaded/leaded free

2.temperature/speed setting before machine be delivered. You can master how to operate it within 10 minutes.

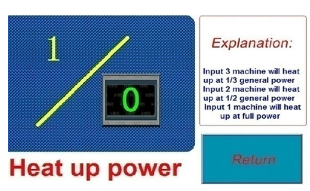

3.Unique program design can adjust the start power consumption andlower the start current. Best choice for customer with limit power supply.

4.Colored touchscreen interface with PLC controller ensure stable operation of machine.

Shenzhen Honreal Technology Co.,Ltdis a national high-tech enterprise,Specializing in smt equipment research and development, production, sales. Services for the world´s top 500 electronic companies.The registered capital of the company is 5 million.Havingexperienced technical team andexcellent technical innovation ability, Creating a better product supply chain and service team and meeting differentcustomer needs is our long-term goal. We will meet customer needs by understanding customers, putting them first and providing valuable services.

Q:How can you guarantee your sales’ quality?

A:We guarantees that every set of machines are under rigorous

testing before they are delivered to you, to ensure the excellent

performance of all products.

Q:How is the training?

A:After buying our machines, your engineers can go to our company or it is so easy to operate

the machine according the training video and user manual,the user manual will come with the machine together.

Q: I would like to ask you if it's possible to have my logo on the

product.

We hope you know that our company perfectly support customized logo

service,we’re do this. Besides, it's totally free,so just tell us

your requirements.

Q: Is it hard to use these machines?

A: No, not hard at all. For our previous clients, at most 2 days is enough to learn to operate the machines.