Shenzhen Honreal Technology Co.,Ltd |

|

Verified Suppliers

|

|

Product introduction:

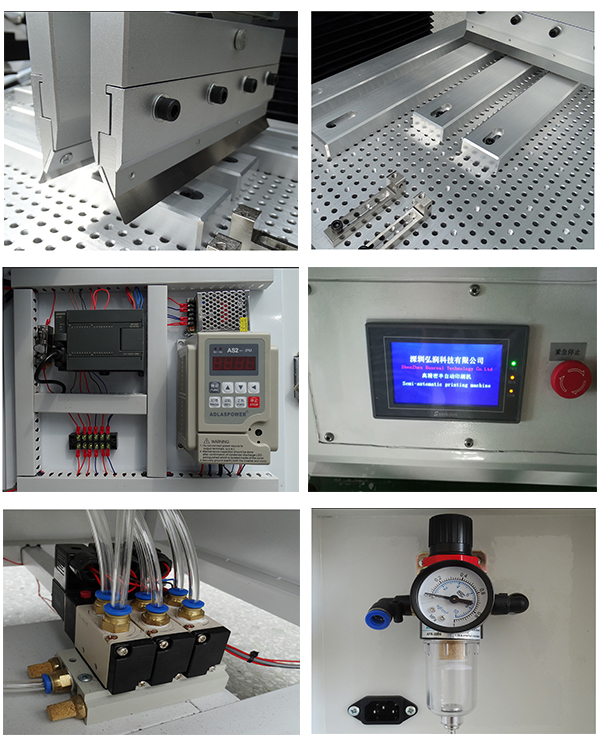

1.Using precision guide rail and the import motor to drive the

blade seat conversion, printing, and high accuracy.

2.Printing scraper can rotate 45 degrees fixed up, easy printing

stencil and squeegee cleaning and replacement.

3. Scraper block can be adjusted before and after the blade, to

choose the right printing position.

4.Combined with a fixed groove printing platen and PIN, easy

installation and adjustment, for single, double sided printing.

5.School Edition way to move a steel mesh, combined with printed

(PCB), X, Y, Z. Convenient fine adjustment.

6.Can be set to one-way and two-way, a variety of printing methods.

7.With the automatic counting function to facilitate the production

of output statistics.

8.Adjustable blade angle, steel blade, rubber scraper are suitable.

9.Touch screen with a screen saver function, the time can be

adjusted to protect the touch-screen life.

10.Printing speed display, can be adjusted.

Equipment characteristics and functions

1.1 Adopting German precision motors and linear guides, the printing of the scraper holder tends to be more stable;

1.2 The printing pressure of the double scraper can be controlled separately by controlling the precision throttle valve behind the small cylinder of the printing head to set the speed of the scraper lifting and lowering to avoid resonance;

1.3 Input total power supply voltage: single-phase 220V 50/60Hz, power consumption 100W, online display of operating status;

1.4 The printing base can be lifted up by 450 and fixed, making it convenient for scraper loading and unloading and steel mesh cleaning;

The 1.5 printing base can be moved forward and fixed, making it easy to match the position of the steel mesh pattern to achieve better printing results;

The 1.6 mesh frame support arm can be adjusted left and right separately, suitable for the printing range of 300-1550mm;

The 1.7 modular printing platform is equipped with a fixed slot and positioning PIN, which is fast to replace and easy to locate, suitable for single-sided and double-sided substrate operations;

1.8 The proofreading method adopts a mesh frame support arm movement to coordinate with the X, Y, and Z correction and adjustment of printed materials (platens), making the correction convenient and simple;

1.9 Adopting Mitsubishi PLC control, human-machine interface touch control, with options for single/multiple printing, as well as manual or automatic methods;

1.10 The scraper seat can be adjusted back and forth, and the printing scraper can be adjusted, according to the needs of product printing;

1.11 Adopting a Xingchen cylinder and a magnetic proximity switch, the workbench moves back and forth, and the printing surface can reach an accuracy of+0.001mm in place;

1.12 Use air pressure of 4-6 kg/cm2, printing table area of 300x400mm and 450x450mm (suitable for larger sizes), printing accuracy of+0.02mm, machine repeatability of+0.02mm;

1.13 Equipped with automatic counting function and frequency setting, facilitating production statistics;

| Technical parameters | |

Function | This unit is used to print solder paste onto PCB board |

| Printing table sizes | 300×400mm(or customized) |

| The frame size | 370×470mm,420×520mm,550×650mm |

| PCB size | 50x50~300×400mm |

| PCB thickness | 0.2 - 5.0mm |

| Printing position fixed | PCB Outer Or Pin Positioning |

| Bedplate fine-tuning | Front/Back±10mm R/L±10mm |

| Printing precision | ±0.02mm |

| Repetitive precision | ±0.05mm |

| Minimum spacing | 0.35mm |

| Air pressure | 4-6Kgf/Cm2 |

| Power supply | 220V 50/60Hz 100W |

| Specifications | ||||

Model No | HR-1068 | HR-1068A | HR-1068B | HR-1068C |

| PCB size (L×W)~(L×W)mm | (50x50)~(300x400) | (50x50)~(300x600) | (50x50)~(300x1200) | (50x50)~(300x1500) |

| Steel mesh size (L×W)mm~(L×W)mm | (370x470~(550x650) | (370x470)~(550x850) | (370x470~(550x1450) | (370x470)~(550x1750) |

| Printing table sizes (L×W)mm | 300×400 | 300×650 | 300×1250 | 400×1550 |

| Machine size (L×W×H)mm | 860×760×1700 | 1060×760×1700 | 1660×760×1700 | 1960×760×1700 |

| Weight | 260kg | 300kg | 340kg | 380kg |

| Company | Shenzhen Honreal Technology CO.,Ltd. |

| Address | No15,Shangnan Hongma Road, Shajing Street, Baoan District, Shenzhen, Guangdong Province, China |

| Tel | +86755 2302 0279 |

| Fax | +86 755 2330 6782 |

| Zip code | 518125 |

| Skype/Whatsapp/Wechat | +8613715227009 |

| Email: | Monica@szhonreal.com |