Shenzhen Luckym Technology Co., Ltd. |

|

Verified Suppliers

|

|

CNC metalworking milling stainless steel brass aluminum titanium CNC turning machine parts:

Quick Detail:

1. Customized according to customer drawing samples

2 Features: material selection, strict requirements of good workmanship

3. Commonly used materials: stainless steel, carbon steel, galvanized steel, aluminum, weathering steel, ceramics, plastics, brass, copper, plastic custom materials, etc

4. Experts/factory/production/OEM/ODM

5. Surface treatment: polishing, painting, brushing, chrome plating, anodizing, screen printing, zinc plating, nickel plating.

6. Testing: professional testing equipment, professional testing team;

Specification:

| Business Type | Manufacturer | |

| Our Advantages | 1. LUCKYM is factory providing CNC machining ,Stamping ,die -casting service for more than 10 years, we focus on client's demand and client's satisfaction | |

| 2. Provide 2D & 3D drawing for modifying | ||

| 3. Competitive price with good quality | ||

| 4. Small order is acceptable | ||

| 5. Short delivery time (7-25days according to order Qty) | ||

| 6. Customized size and specification /OEM available | ||

| 7. Near Shenzhen and Guangzhou, convenient transportation | ||

| Application | Automobile, Motorcycle, Bicycle, Scooter, Aerospace ,Machinery, electronics, Medical , 5G ,furniture, construction and other industrial uses | |

| Materials | Stainless Steel | SS201, SS303, SS304, SS316 etc |

| Steel | Q235, 20#, 45# etc | |

| Brass | C36000 ( C26800), C37700 ( HPb59), C38500( HPb58), C27200(CuZn37) , C28000(CuZn40) etc | |

| Iron: | 1213, 12L14,1215 etc | |

| Bronze | C51000, C52100, C54400, etc | |

| Aluminum | Al6061, Al6063,AL7075,AL5052 etc | |

| Titanium | Gr1, Gr2, Gr3, Gr4,Gr5, Gr7, Gr9, Gr11, Gr23, etc | |

| Magnesium | AZ31, AZ61, AZ91,etc | |

| Plastic | ABS,PC,PE,POM,Nylon,Teflon,PP etc | |

| Machining | Turning, Milling, Drilling, Grinding, Cleaning, | |

| Main equipments | CNC lathe, CNC milling, Stamping machine, | |

| Automatic lathe, Grinder, Tapping | ||

| Drilling machine...etc | ||

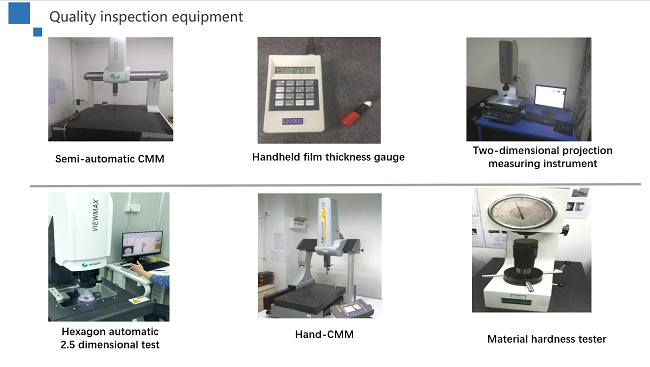

| Measuring & Testing equipments | CMM, Profile Projector, Rockwell Hardness Tester, Vickers Hardness Tester, Roughness Tester, Micrometers, height gauge, Calipers... etc. | |

| Accuracy | Accuracy Of Machining:+/-0.003mm | |

| Accuracy Of Grinding:+/-0.003mm | ||

| Surface Roughness:Ra0.5 | ||

| Parallelism:+/-0.003mm | ||

| Verticality:+/-0.003mm | ||

| Concentricity:0.003mm | ||

| Surface Treatment: | Polishing, Deburring, Chrome Plating, Ni Plated, Zinc plated, Silver platinng | |

| Anodizing various colors, Carburizing Nitriding, Heat Treatment, etc... | ||

| MOQ | 1 ~10000pcs. | |

Products show

1. Different types of CNC processing products;

2. Welding bending stamping parts and laser cutting parts;

3. Precision manual displacement platform;

4. Ceramic parts.

Quality guarantee:

Our advantage

1. Standard parts, 90% can be shipped within 3 days. Assembly

products, which can be delivered according to customer

requirements,Negotiate delivery dates for customized

products according to customer requirements

2. Non-standard customized products, developing new products

according to customer drawings

3. The company has strict internal quality management system and

perfect supplier quality management system

4. The whole series of products have 3D models,Calculation and

selection support to improve design efficiency.Pre-sales support

and after- sale technical training services

FAQ:

1. Are you a manufacturer or a trading company?

We are a factory located in Shenzhen, China, with 10 years of rich experience. Our facilities are relatively complete, including 3D quality testing equipment, ERP system and 40 machines.

Packaging and transportation: carton, wooden box (size can be negotiated);