Guangzhou Tianyuan Silicone Machine Technology Co., Ltd. |

|

Advanced Silicone Mobile Phone Case Making Machine For Silicone Mobile Case Manufacture

The most common application for silicone rubber is the production of LSR parts. LSR parts are used in a range of different industries. Their steam resistance and low compression set make them an excellent choice for gaskets and hardware in consumer appliances such as microwaves. Their conductivity and fatigue resistance make them ideal for electronic interfaces on keyboards or touchpads. Their oil and heat resistance offers long-term durability in automotive components.

Machine Model Parameter

| Machine Model | Shot Volume | Injection | Injection | Clamping | Opening Stroke | Tie-Bars Space | Ejection Force | Machine Weight | Motor Power |

| TYM-L5058 | 165g | 30g/s | 700kg/cm2 | 130T | 250-550MM | 500*580MM | 4.3T | 5.3T | 12.1kw |

| TYM-L6068 | 300g | 30g/s | 700kg/cm2 | 130T | 250-550MM | 600*680MM | 4.3T | 5.5T | 12.1kw |

| TYM-W4545 | 165g | 30g/s | 700kg/cm2 | 130T | 200-700MM | 450*450MM | 4.3T | 5.2T | 12.1kw |

| TYM-W5050 | 300g | 30g/s | 700kg/cm2 | 130T | 200-700MM | 500*500MM | 4.3T | 5.3T | 12.1kw |

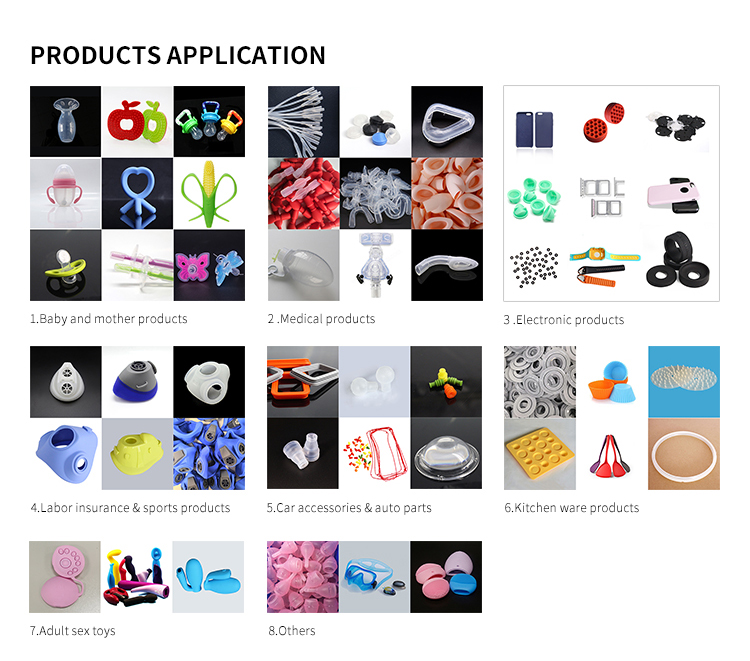

Applications

Our LSR injection molding machine is widely used in medical

industry, food industry, infant industry, diving industry,

insulator industry and other LSR production field. Furthermore,

with abundant technical strength,Tianyuan can design the LSR

injection molding equipment exactly based on the customer's

requirements, and can provide the turn-key solutions, such as the

LSR feeding machine, LSR injection molding machine, LSR mixing

system, color adding system, LSR mould and so on.

Our Services

Pre-sale service

According to customer's investment budget, plant planning and other forms of pre-sales services to ensure customer's planning is reasonable, standardized and cost-saving and provide matched mold scheme and recommend suitable machine according to customer's product.

On-purchase service

Enable the relevant personnel to be familiar with the operation of the TYM's machinery and understanding the machine maintenance.

1) Installation of LSR machine and new machine commissioning service

2) Machine operator training

3) Training of relevant technicians

After-sales service

1) Free training till relevant personnel is able to operate and maintain independently

2) Help to solve and reply technical problem and question timely, TYM will arrange professional engineer for site instruction

3) TYM will provide technical guidance for free if customer need new equipment or expand(rebuild)

4) TYM will give priority to customer according to customer's upgraded demand when TYM's equipment is upgraded.

FAQ

Q1: Is there any difference between horizontal and vertical LSR molding machine?

A: The vertical LSR machine is suitable for silicone parts which needs to be removal by manually, after the mould open, the bottom moldboard will slide out, and you can remove the finished Parts; manually and it is very safe. And vertical LSR machine is also suitable for producing some LSR parts which has plastic or metal inserts inside, because we must put the plastic inserts on the mold first before close the mould, because the moldboard of the vertical LSR machine is up and down, when we put the inserts on the bottom moldboard, the inserts won ‘t drop down.

Q2: What is the property difference between liquid silicone rubber (LSR) material and solid silicone rubber material?

A: The vulcanizing agent of LSR material is platinum, there is no outgrowth. Environmental Performance is very good, the weather resistance, Tear strength. Resistance to fatigue performance are much better than the solid silicone rubber material. The vulcanizing agent of the solid silicone rubber material is peroxide, and there will be peroxide dissolved out slowly after laying aside for very long time.

Q3: What is the difference between liquid silicone rubber (LSR) products and solid silicone rubber products?

A: The LSR is injection molding process, the finished LSR parts has much better transparency and the tearing strength, rebound resilience, yellow-color changing resistance, heat stability, water-tolerant. expansibility, aging resistance, weather resistance, and less flashing. And the finished LSR parts is very precise.

The solid silicone rubber product is NOT so good on the transparency, tearing strength, extension, tearing strength and so on, and it has much flashing, the finished solid silicone rubber parts are not so precise.

Q4: What's the advantage of TYM machine?

A: Our TYM LSR molding machines are exported to Europe and the United States and more than 30 countnes in the world, and we give the professional service for more than 10 years. Our business scope includes medical, baby products, electronic ,diving products ,kitchenware industry, we supply the whole solution including the LSR moulds ,and we have rich experiences to share.