Shenzhen Linquan Technology Co., Ltd. |

|

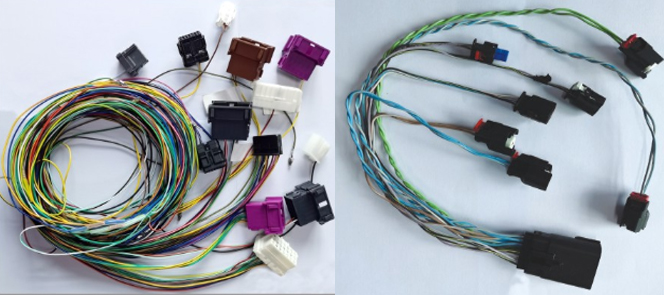

Automatic wire cable cutting stripping and terminal crimping machine wire types

Equipment Configuration

With the German high pixel image detection system

Module(THK),Electric(YASKAWA),Cylinder(SMC),Sensor(Omron),CCD

Camera(Germany Basler),Reducer(Xinbao)

The maximum speed can reach to 1000pcs/hr

Equipment Function

It can process 35 different specifications and colors of wire

Terminal visual detection system,pressure inspection,insertion

drawing force detection

Double-end crimping with the function of double-end housing

Insertion

Simultaneous multiple housing insertion

Technical Parameters

| Mechine Function | Fixed length cut at both ends, Peel off, Double-end crimping, Double-end insertion, Manual feeder, Adjust height on touchscreen, Discharge defective products through inspection |

| Capacity | Crimping and inserting at both ends around 1000pcs/hr |

| Drive Mode | Mitsubishi SERVO MOTOR, Drive, IPC |

| Wire Size | 0.13mm²—4.0mm² |

| Mould Assembly Type | Assemble AS40, AS42, AE30( Customized Acceptable) |

| Wire Cutting Length | 280-9999mm |

| Cutting Precision | Cutting length<100mm,Error range 0.5mm+(Setup cutting length*0.002) |

| Stripping Length | Both sides(crimping ends)0-15mm |

| Penetraction Depth | MAX 3mm |

| Crimping Capacity | 3TON Servo mute specifications |

| Detection Device | Wire presence, Wire overload, Terminal presence, Terminal overload, Stripping and crimping visual monitoring, Pressure manager, Housing presence, Insertion error detection,Tinning surface detection |

| Power Source | 3 phase/380V/50Hz |

| Power | 10KW |

| Compressed Air | 0.5Mpa |

| Equipment Size | L3200*W4000*H1900mm |

| Weight | 1500KG |

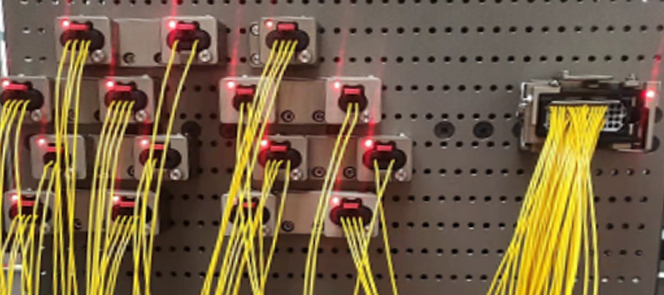

Wide variety with up to 36 wire types

The different wire types for versatile wire

harness production are available on the

Loong machines without the need for

changeovers. The automatic wire changer

provides up to 36 different wires from the

entire cross-section range. This enables the

range of wires required in the construction of control

cabinets,which to be covered perfectly.

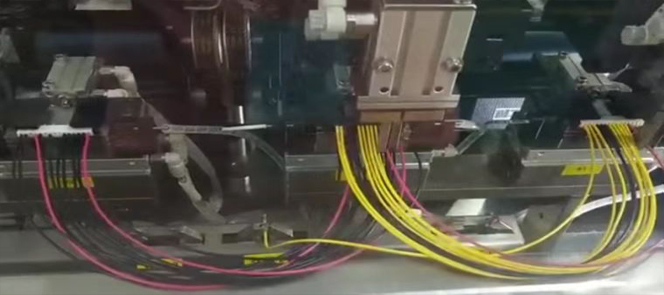

Automated inkjet printers mark the wires

The marked wires are picked up by a shuttle system and guided in

loops to the processing machines.

Continuous data flow and traceability Production data can be sent

directly to the machine via a network. The quality data

from the production process is saved for each wire harness and

traceability is guaranteed at all times.

Cutting Precision

It is based on a capacitive measuring principle, is integrated in

the blade holder and can be operated using any standard

stripping blade.

The sensitivity of the monitoring can be configured using setting

parameters. Defective wire ends are detected automatically

and rejected

Cutting length shorter than 100mm, error range 0.5mm+

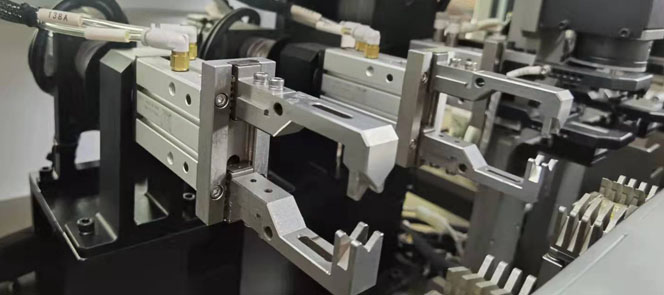

Self-Developed Crimping Head

Pass CPA+ pressure stability test CMK can reach to 4.0 or

higher,far higher than the industry standard 1.6(Detailed data

reports can be provided)

Higher stability and accuracy

Adjust height on touchscreen

The crimping machine head can be added according to customers need.

The equipment is modular and can be matched according to product

types.

3 or 12 modules can be selected, as required.

Self-Developed CCD Visual Inspection

CCD Visual Inspection detect the Coreless crimping, Crimping

without stripping, Deep and shallow crimping, Core wire splay, Half

packing of insulation layer and provide alarm.

Core Wire Online Inspection System

Detect the Copper Wire Inspection Number and Stripping Length

Inspection and provide alarm.

Self-Developed Online Pressure Inspection

Detect the Terminal Presence, Deep or shallow crimping and Coreless

crimping and provide alarm.

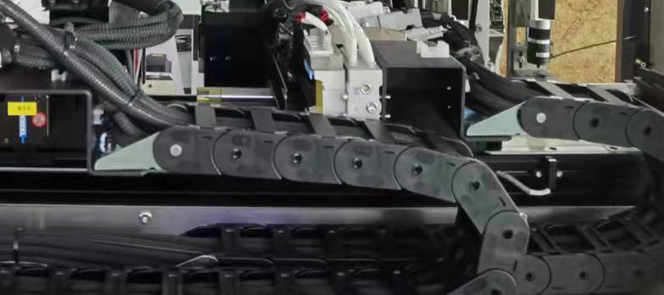

Magnetic Levitation Linear Motor

Fast handling Speed

High position accuracy

Quiet,long service life, low maintenance cost

High precision inserting unit

Untwisting of the wires

Unwound wires are always twisted. A special

untwisting module removes this twist. The

wires are then 100% straight, which is crucial

for the subsequent fully automatic insertion.

Versatile seal insertion

Double-end crimping with the function of double-end housing

Insertion.

Simultaneous multiple housing insertio.

The latest generation seal

module creates the ideal conditions for the

efficient insertion of conventional seals and mini-seals.

Efficiency reach 2.5 sec per single-sided loading.

Drawing force inspection and discharge defective products while

selecting keep the qualigy.

Kinds Line Stroing Function

Exquisite structure and beautiful

appearance

Multiple wire storing, meets various

wire harness process needs

No limit on the housing type, 20 different kinds of housing can be

inserted at the same time.

High flexibility and simple operation

The new fully automatic blockloaders with enlarged mounting pallets

ensure even greater flexibility for specific manufacturing across a

wide range of applications. They process wire harnesses in a single

process step from A to Z and open up new possibilities for the

required wire harnesses. Already created wire harnesses can be

loaded again in seconds and re-produced.

Processing samples