Shanghai Liangui Technology Co., Ltd. |

|

Verified Suppliers

|

|

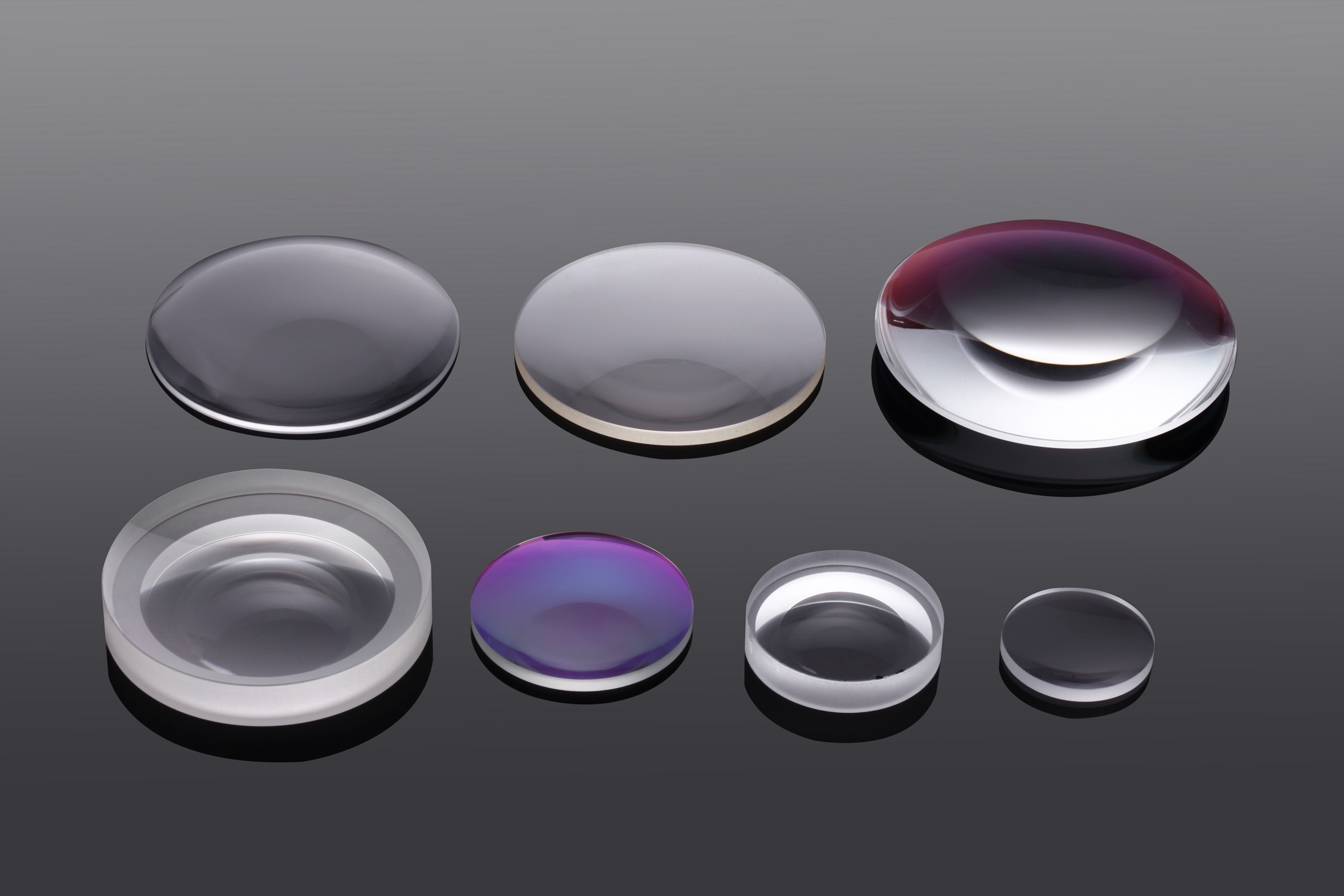

Optical Lens Plastics Parts Plasma Surface Treatment Equipment

1. Product Introduction

Plasma cleaning is the removal of impurities and contaminants from surfaces

through the use of an energetic plasma or dielectric barrier discharge (DBD) plasma created from gaseous species. Gases such as argon and oxygen, as well as mixtures such as air and hydrogen/nitrogen are used.

The plasma is created by using high frequency voltages (typically

kHz to >MHz) to ionise the low pressure gas (typically around

1/1000 atmospheric pressure), although atmospheric pressure plasmas

are now also common.

Before coating:Remove organic residues on the surface after centrifugal cleaning and ultrasonic cleaning, and play an active role in the subsequent coating technology.

After coating: To clean overflow plating.

This Small vacuum plasma cleaning machine using inductive coupling type working principle, and plays an outstanding role in insulation of microwave tube and parts. It is suitable for handling sensitive products with high cleanliness.It can deal with plastic, biochemical materials, PDMS, glass or metal semiconductor, ceramics, composite materials, polymer and other materials, It has the effect of super clean surface, sterilization, improving wettability change, surface property change and improving binding force on the material surface.

2. Characteristics

3. Technical Parameters:

| Name | Specification parameters |

| Vacuum degree | 30Pa-100pa |

| Gas flow | 0-100ml/s |

| Cleaning time | Adjustable (1-9999s) |

| Cooling mode | Air cooling |

| Gas channel | Two-way working gas; Argon, hydrogen, oxygen, nitrogen, air,etc. |

| Control Systems | PLC + Touch screen |

| Vacuum cavity temperature | <50 ℃ |

| Vacuum pump | Oil pump/dry pump (optional) |

| Power supplies | AC220V(±10V) |

| Remarks | Specialized equipment can be customized for different material forms, sizes and production capacity. |

4. Equipmemt Composition:

Plasma cleaning machine is composed of reaction chamber (also known as vacuum chamber), vacuum system, discharge system, electrical control system, intake flow control system.

5. Equipment Operation

1) Open the vacuum chamber door, put the items to be processed into the vacuum chamber, and close the vacuum chamber door;

2) Turn on the main power switch and set parameters through the touch screen;

3) The equipment will run automatically according to the set parameters (vacuum → air intake → discharge → empty). After the treatment, the buzzer will ring to remind the operator that the experiment has been completed;

4) Open the vacuum chamber door cover and take out the processed items.

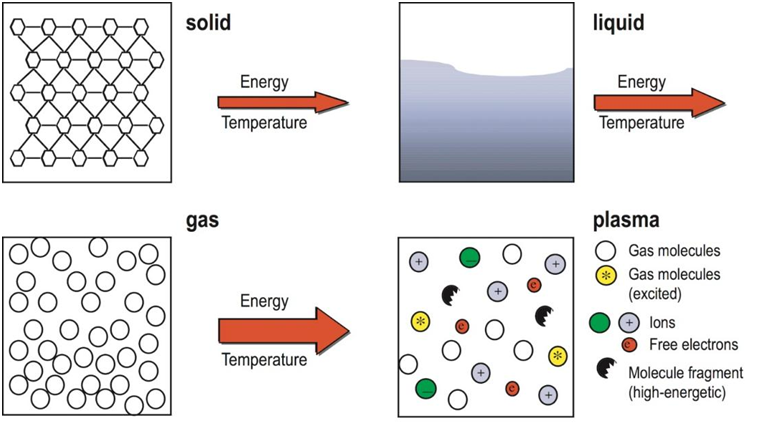

6. Principle of Plasma Cleaning

Plasma is a kind of existing state of substance. It is usually juxtaposed with the solid, liquid and gaseous states of a substance and is called the "fourth state of matter". It can use the plasma high-energy particles and the material surface physical and chemical reaction to realize the material surface activation, etching, decontamination and other processes, as well as the material friction coefficient, adhesion and hydrophilic and other surface properties of the purpose of improvement.

The surface of the treated material is cleaned chemically and physically by making the plasma and material surface contact and react using plasma cleaning technology (low temperature plasma characteristics) in order to improve surface smoothness, implant new chemical functional group and realize etching.

(1) Cleaning and activation for material surface

(2) Form new functional group- Chemical effect.

New functional groups will be introduced, such as hydrocarbyl, amidogen and carboxyl, all of which are active groups and could improve the activity of material surface significantly.

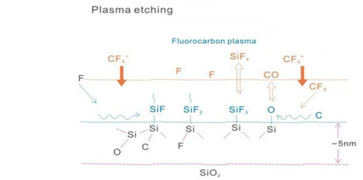

(3) Plasma etching.

Plasma etching means a process of removing volatile gaseous substance generated by creating plasma of a kind of proper gas chosen and substance on solid surface.

Plasma etching technique is actually a kind of reactive plasma process. Its main advantages include high etching rate and evenness. The technological parameters of plasma play a vital role in etching effect.

7. Plasma Cleaning Process:

8. Plasma Cleaning Advantages:

9. Comparison Before and After Plasma Treatment:

The contact Angle of liquid on the surface of solid material is an important parameter to measure the wettability of liquid on the surface of material.If θ<90°,the solid surface is hydrophilic, and the smaller the Angle, the better the wettability; if θ>90°, the solid surface is hydrophobic.

The measurement of the dyne value is very common in printing, coating, laminating, welding and other applications. It can reflect the ability of the material surface to bond easily. In general, the greater the dyne value, the better the bonding performance of the surface with another material.

10. Common Applications:

Surface modification of polymer materials Improves surface bonding property

Removal of oxide residue of electronic components, improve the bond quality and enhance the bonding effect.

Glass substrates remove organic contaminants

Removal of oil from metal surfaces

Graphene and other powder cleaning modification

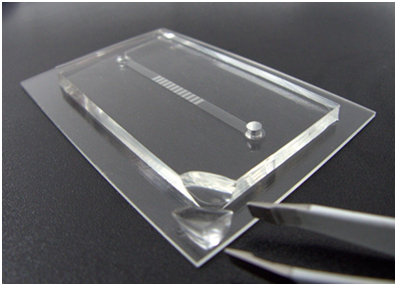

PDMSSurface activated bonding

11. Qaulity Assurance and After Salse Services:

1 year warranty,If the equipment fails during the warranty period,supplier should arrange personnelto follow up and deal with until troubleshooting.

1) Accessories and Information with equipment.

When the equipment is delivered, the supplier shall provide a complete set of technical documents concerning operation, commissioning and maintenance, including operation and maintenance manuals.The maintenance manual should contain circuit diagram, gas circuit diagram and pipeline diagram.

2) The installation

Provide all details needed to prepare for site equipment installation.

3) Training

During installation, training can be provided remotely, including normal operation, repair and maintenance, analysis of tank problems and emergency procedures.

4) Equipment delivery to use and after-sales technical service

Supplier shall provide the documents of equipment installation, operation and maintenance, and technical support for operation training.Also a copy of the warranty indicating the effective date and coverage of the warranty and the contact person of Seller.