Shanghai Liangui Technology Co., Ltd. |

|

Verified Suppliers

|

|

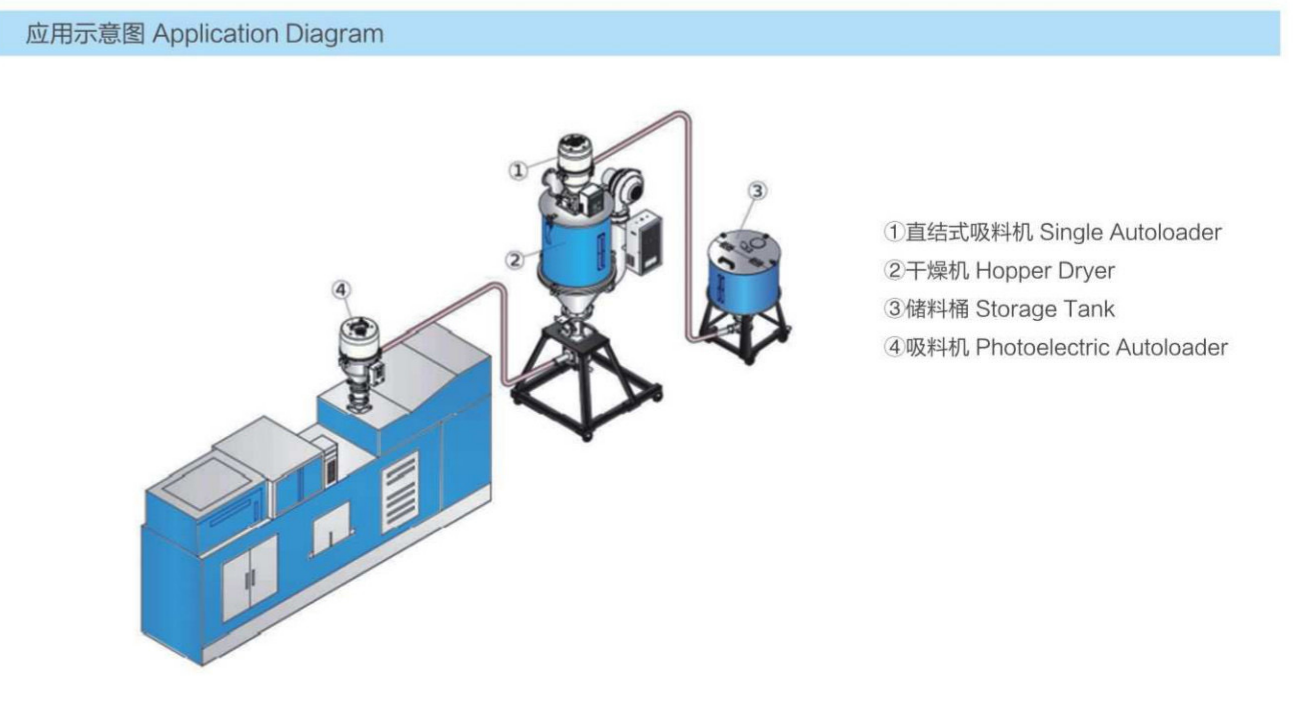

Injection production plastics material automatic feeding autoloader

Single Autoloader adopts carbon brush high-speed rectificative motors. All these models also feature light wight, small footprint, great suction power, easy installation and operation, suitable for conveying new material. All models of ZAL series adopts stainless steels hopper to ensure material no contamination;surface polish treatment, beautuful and exquisite, appearance; it can be mounted onto hopper dryers or injection molding machines, easy to install, savce spacem conveying capacity up to 200kgs/hr.

Fearures

Easy Maintenance / Quick Cleanup

AL series single auto loader us designed to provide rapid

transportation of free-flowing for virgin resin or regrind resin

directly to injection molding machine. The design of hinged upper

conver of cacuum motor ensures quick cleanup time and easy

maintenance.

The single-phase vacuum suction motor creates a flow of air which carries the plastic granules into the hopper through the material conveying hose during setting suction time. The granules are then discharged directly into the processing machine hopper. The cycle is repeated until both machine hopper and hopper loader are full.

Reliable Performance

The setting and displaying for loading time, loading fuction and mode selection digitally are controlled by microprocessor. Fault diagnosis & Alarm are provided as standard features of the control. All models are built by the highest quality with stainless steel for providing consistant, reliable performance.

Company Introduction

Founded in 2019 and located in Jiading District, Shanghai, Shanghai Liangui technology is committed to promoting human prosperity and development with technology, focusing on the manufacturing and sales of machinery and equipment in the injection molding industry, and operating and managing according to the values of integrity, innovation, respect, enthusiasm and challenge.

At present, the company has established two business divisions: injection molding equipment division and intelligent equipment division. The products include injection molding, drying, conveying, mixing, mold temperature, recycling and other equipment, as well as the central feeding system, customized intelligengt picking and placing system and the whole plant planning. It covers all injection molding applications.

The company has a number of professional tehcnical teams and experienced sales teams, with undergrante and research degrees accounting for more than 80% of the total number of the company. Adhering to the purpose of "customer first", the company has provided high-quality products and automation solutions for many well-known enterprises in domestic and abroad, and is the most trusted factory equipment supplier for factories and agents in domestic and aboard.