Shenzhen Yizhuo Electronics Co., Ltd |

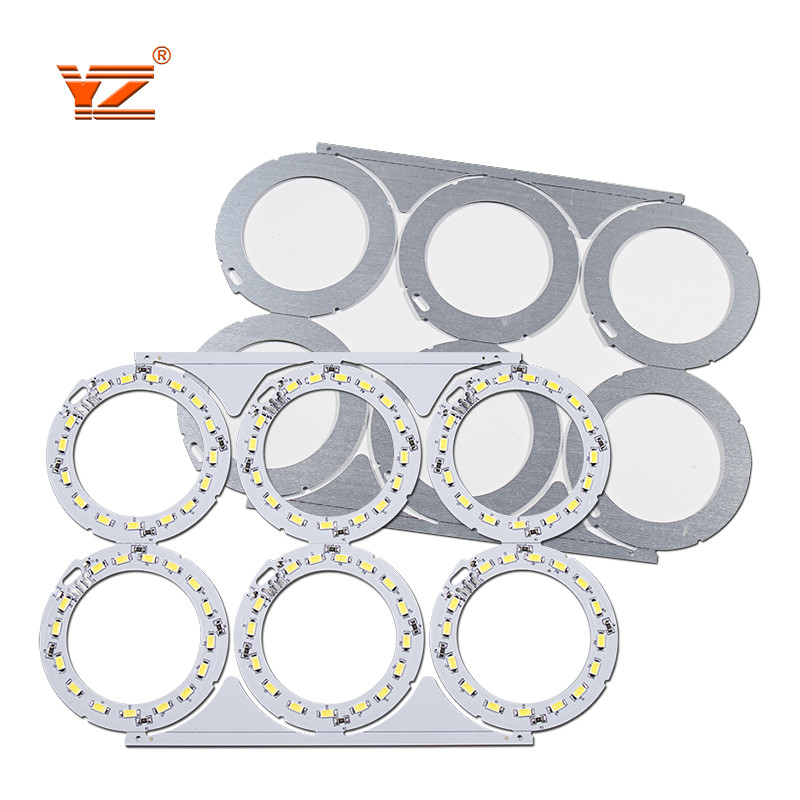

PCBA Marker Led Pcb Board Eesign Assembly Led Bulb Circuit Board

After designing and printing the circuit boards, they have to be connected so the electric messages can be properly sent between them. Wiring them together is what makes the electronic device function.

Technical Specification |

Minimum line width/gap:3.5/4mll(laserdrill) Multilayers:0.40-4.0mm, Min Solder Mask Bridge:0.08mm Aspect ratio: 8: 1

| |||

In the SMT process, reflow soldering takes place at this time, as well. The board is sent through a furnace, which melts the solder paste, allowing it to flow as necessary, before the board passes through a series of coolers that gradually bring the temperature down, solidifying the solder on the board and cementing the components in place.

Shenzhen Yizhuo Electronics Co., Ltd. is a national high-tech enterprise certified to ISO9001: 2015 international quality management system. We have CE, ROHS, UL certification. It was founded in 2012 and factory area consists of more than 6,000 square meters, 131 employees, and two shifts. We have the capability to manufacture aluminum PCBs, FR4 PCBs, LED PCBA, and other related products. We are also providing services like PCB design, PCB assembly, and LED SMT board processing for PCB designing services. The products are widely used in lighting, electronics, communications, automotive and other industries that require heat dissipation. Our professionals work in close association to understand the specific requirements of our clients. In our quality testing unit, we meticulously test each product, thus results in their compliance with international quality standards. We can do ODM or OEM one-stop service for our customers.

We are supported by a ‘state-of-the-art’ infrastructural base and team of enthusiastic and skilled professionals. we have divided our well-developed infrastructural base into various units such as procuring, designing, manufacturing, quality testing, R & D, sales marketing, warehousing packaging, and more. This facilitates us to deliver totally defect free range product to our clients at the leading market prices and equipped with the latest machinery and innovative technology in order to meet the large-scale orders of customers. With a senior management team and R & D design team with an average industry experience of more than 10 years, our products are selling well around the world.

FAQ:

Q1. What specifications do you need for PCB quotation?

A: We need your PCB Gerber file,board thickness,copper

thickness,surface finishing and quantity to quote you.

Q2. How about the Shipping cost?

A: The shipping cost is determined by the destination, weight,

packing size of the goods. Please let us know if you need us to

quote you the shipping cost.

Q3: Do you have MOQ limited?

A: We don’t have any MOQ limited, the minimum order we accept is 1pcs.