Shenzhen SMTfly Electronic Equipment Manufactory Ltd |

|

Printed Circuit Board Automated Optical Inspection AOI-PCB AOI Inspection Machine,SMTfly-S810

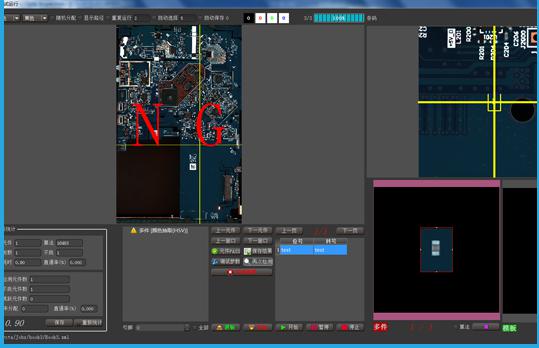

Various vector image algorithms to get the best inspection capability

The vector image algorithms include logic operation ,distance of luminance boundary, chip tracing,OCR/OCB Luminance/color template matching, color distance, color distance, color extraction (RGB&HSV),VALUE-range of luminance offset of luminance, the minimum variation span of luminace,etc.More than 30 Kinds of the most advanced algorithms

Germany imported 5.0 MP Industry cameras

Wight a high-color reproduction, collocation a high-resolutiontelecentric lens, high NG identification, provide high-definition image output the AOI

Control system

All major components are used internationally renowned brands, in the premise of ensuring the stability and accuracy of the movement equipment with high service life and low failure rate.

The entire PCB match capability can detect extra part at any location

The entire PCB match function

High frame rate industrial cameras with telocentric lens

High-speed dynamic image acquisition can acquire hundreds of images per second, combined with the software entire board matching algorithm, can be used detect extra parts,foreign matter, scratches and other information on the PCB

Multi machines one operator, intelligent communication

Central server mode that gathers information from all the test machines to facilitate the integrated management of production, multiple machines need only one operator

Printed Circuit Board Automated Optical Inspection AOI-PCB AOI Inspection Machine Feature:

Automated Optical Inspection AOI-PCB AOI Inspection Machine Specification:

| Category | Item | SMTfly-810 |

| Recognition system | Inspection | The vector image algorithms include logic operation, distance of luminance boundary, chip tracing,OCR/OCV luminance/color template matching, color distance, color extraction (RGB&HSV)Value-range of luminance, offset of luminance, the minimum variation span of luminace,etc….more than 30 kinds of the most advanced algorithms |

| Camera | Distal high speed CCD 5m pixel camera,20um(12um,15um,10um for option) | |

| Lens | High-resolutiontelecentric Lens | |

| Lamp-house | Rings RGB led lamp-house | |

| FOV | 40.95*40.95mm(20um)30.68*30.68(15um) | |

| 0201 Chip | <7.6m | |

| Per-image Time | <240ms(15um) | |

| Paste Printing Time | Missing,shift,skewed,tombstone,billboard,overturned,reversed polarity,wrong,damaged | |

| Component Defects | Overflow,insufficeient,short solder,stain | |

| Solder Defected | Overflow,insufficient,short solder, solder void | |

| Wave Soldering Inspect | 01005&0.3mm pitch()15um | |

| Mechanism System | PCB Conveyor | Left to right ,PCB fixing:bottom-up,PCB warp correction ,Automatic PCB loading and unloading ,Adjustable clearance,Conforming SMEMA standard,Orbit clearance: 900±20mm |

| PCB size | 50×70mm-400×330mm | |

| PCB thickness | 0.5mm – 3.0mm | |

| PCB warp Tolerance | <2mm | |

| Component Clearance | TOP≤25mm, BOT≤25mm | |

| Driver | AC server, camera moves in the directions of X/Y | |

| Positioning accuracy | <10um | |

| Moving Speed | 500mm/s |

Printed Circuit Board Automated Optical Inspection AOI-PCB AOI

Inspection Machine:

If you want to buy the machine,please contact us,we'll try our best to help you.