Lingman Machinery Technology (Changzhou) Co., Ltd. |

|

Verified Suppliers

|

|

1. Description

Compared with other chucks, the hydraulic four-jaw chuck has the advantages of fast clamping, large clamping force, wide clamping range, high safety and high reliability. Therefore, the hydraulic four-jaw chuck has a great application space in processing and clamping various rectangular and irregular workpieces.

The working principle of the hydraulic four-jaw chuck is that the

hydraulic oil enters the cylinder from the cylinder inlet, and the

cylinder and the piston form a closed cavity. , the support sleeve

moves down together to compress the disc spring, the snap ring

moves down, and drives the three slips to move horizontally away

from the center to achieve the purpose of releasing the drill pipe.

The hydraulic four-jaw chuck adopts strict chuck manufacturing

method and is suitable for professional lathes. No matter it is

applied in various workshops, it has been well received by the

industry.This product is durable and has high speed smooth

operation. High precision of positioning and repetition, large

clamping force, suitable for automatic production. It is very

suitable for processing square parts and other special-shaped

parts.

The collet reduces the weight of the lathe and increases the service life. Moreover, the installation is very convenient, and the connection method adopts the industry standard. It only needs to be equipped with a flange that matches the chuck, and there is no need to change the structure of the machine tool.

2. Performance Parameters

| Product name | CNC lathe chuck |

Model number | 4H-10 |

Wedge stroke | 19mm |

Claw stroke/diameter | 8.8mm |

Clamping diameter | 31-254mm |

Max. D.B pull | 42.6KN |

Max. clamping force | 110.7KN |

Weight | 36.3KG |

Max.working pressure | 2.7Mpa |

Max. number revolutions | 3400 r.p.m |

Applicable rotary cylinder | TH-1075 |

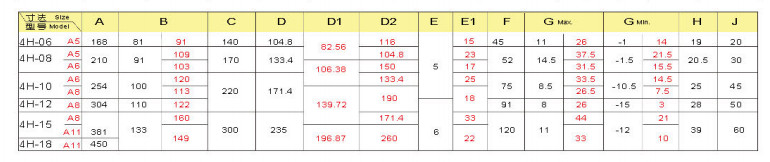

3. Dimensions

4. Advantages

| a. Full stroke design |

| b. Wide range of applications, diversification of processing profiles |

| c. High repetitive positioning accuracy |

| d. Low maintenance cost, long service life |

| e. Multiple configurations are available e.1 Solid or hollow e.2 Comb-type or mortise-groove type claws |

5. Our Service

| a. We are the direct factory with good price and fast lead time. |

| b. Professional design team work with you. |

| s. Professional QC team to guarantee the high quality. |

| d. Providing OEM & ODM service |

6. Production Line