Lingman Machinery Technology (Changzhou) Co., Ltd. |

|

Verified Suppliers

|

|

Hydraulic Rotary Chuck Cylinder Center Solid TH Series for CNC Lathe Machine

1. Description

Our hydraulic cylinder block is made of aluminum alloy and is of lightweight design with little inertia and light weight, which can greatly reduce the load on the spindle of the machine tool. The balance design of this cylinder is light and dense, high speed operation can maintain uniform shape balance, and can reduce the load of machinery. Solid rotary cylinder high-speed continuous rotation and balance, internal parts are all imported original. This ensures long cylinder life due to the high quality cylinder seal and high accuracy. Can be customized according to customer needs high pressure type, long stroke type, large caliber type. The drain hole pipe must be connected to the oil pressure tank separately to avoid back pressure.

2. Performance Parameters

Model number | RH-200 |

Push side | 310.0cm2 |

Pull side | 286.3cm2 |

Stroke | 35mm |

Max. numbers of revolutions | 4000 r.p.m |

Max.working pressure | 4.0Mpa |

Weight | 20.4KG |

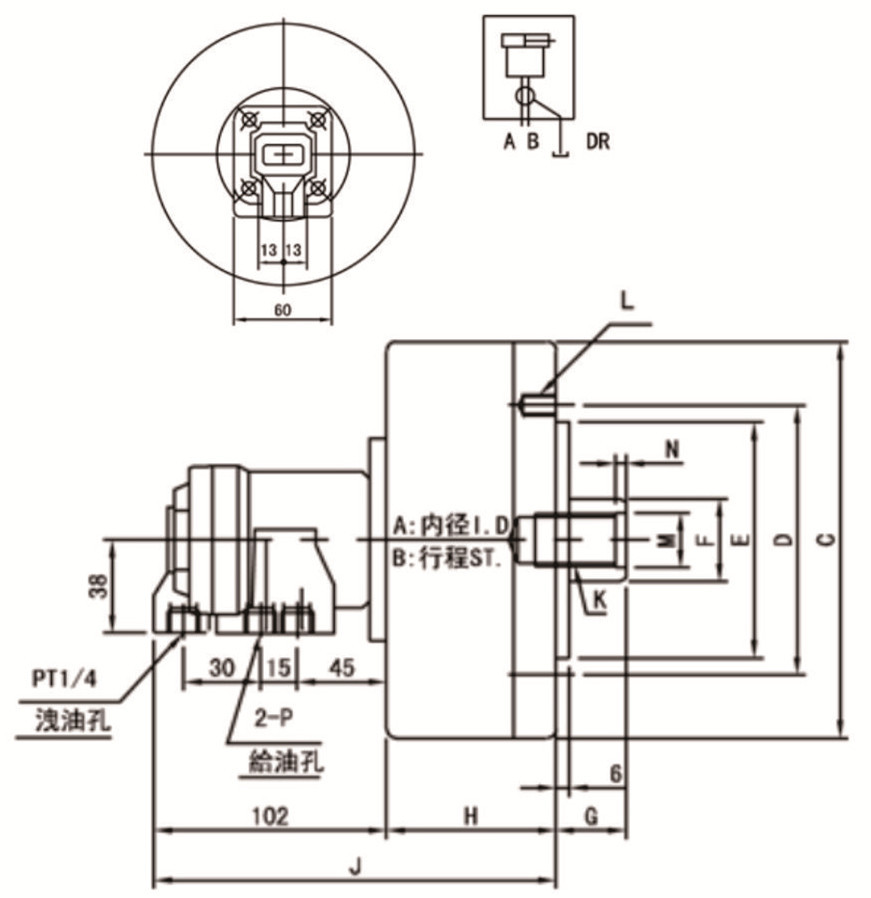

3. Dimensions

| Specifications | A | B | C | D | E | F | G | H | J | K | L | MH8 | N | 2-P |

| RH-200 | 200 | 35 | 245 | 145 | 120 | 55 | 35-70 | 130 | 231 | M36X60 | 12-M16X30 | / | / | PT3/8 |

4. Advantages

| a. Full stroke design |

| b. Wide range of applications, diversification of processing profiles |

| c. High repetitive positioning accuracy |

| d. Low maintenance cost, long service life |

e. Multiple configurations are available |

5. Our Service

| a. We are the direct factory with good price and fast lead time. |

| b. Professional design team work with you. |

| s. Professional QC team to guarantee the high quality. |

| d. Providing OEM & ODM service. |

6. Production Line

7. FAQ

Q: What parameters should we offer us for proper quotation?

A: Application, dimension, quantity, packing requirements.

Q:What's your advantages?

A:Honest business with competitive price and professional service on export process.

Q: Can we visit your company to inspect products before delivery?

A: You are welcome to visit our company to inspect us and our

products.

Q:What's your lead time?

A: Within 15-35 days after confirming the order.

Q: What are your payment terms?

A: T/T, L/C, West Union, Paypal, etc.