Lingman Machinery Technology (Changzhou) Co., Ltd. |

|

Verified Suppliers

|

|

1. Description

Our company mainly manufacture different kinds of chucks which are applied in laser cutting machines, CNC lathes, auto lathes and so on.

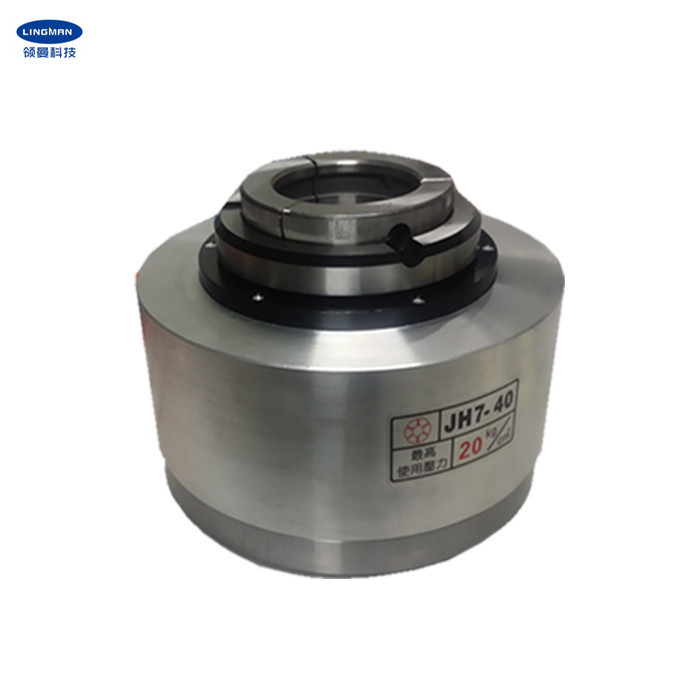

This collet has an internal mechanism inside the barrel, eliminating the need to install a rear revolving barrel. The clamping accuracy is between 0.05-0.08mm (the end face is measured at 10mm), but do not reduce the inner hole of the spindle. The use of light alloy cylinder body, light weight, good heat dissipation, can effectively reduce the temperature. The air pressure has a soft grip, which can keep the workpiece from being deformed when clamping soft workpieces. The power source can be hydraulic or pneumatic. The collet adopts powerful hydraulic clamping and can be widely used for heavy pipe cutting. This collet is suitable for laser cutting, NC, CNC, 4.5 axis. Besides, a shield should be installed to prevent the clip from breaking and hurting people. And do not use cutting fluid if the waterproof ability is insufficient.

The rotary chuck series has a built-in oil-pneumatic rotary cylinder, and the user can complete the setting of the workpiece clamping system in a very short time, and quickly start various processing operations. In addition, the design of the quick-change vice jaws of the quick-precision rotary chuck can help customers to face a variety of small and diverse processing operations more flexibly.

Except this kind of chuck, other types of chucks are also provided.

2. Performance Parameters

Model number | JH7-40 |

Push side | 87.7cm² |

Pull side | 31.1cm² |

Allowable pressure | 2.0/0.8MPa |

Limit speed | 1600r.p.m. |

Max. clamping force | 13.1/5.2 KN |

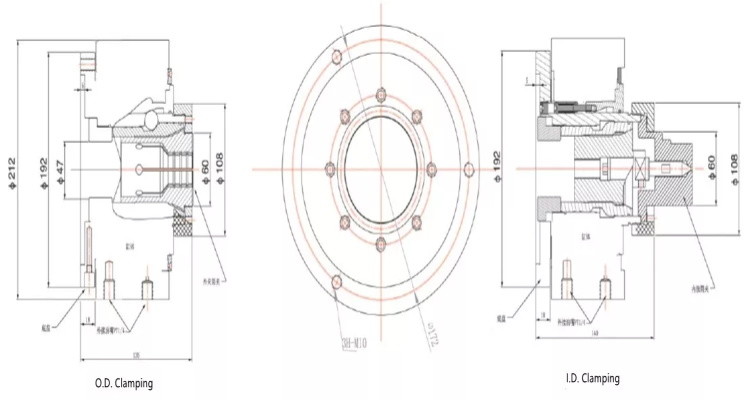

3. Dimensions

| Specification | A | B | C | D | E | F | G | L | I | H |

| JH7-40 | 192 | 155 | 46 | 65 | 94 | 192 | 5 | 128 | 172 | 18 |

4. Advantages

| a. Full stroke design |

| b. Wide range of applications, diversification of processing profiles |

| c. High repetitive positioning accuracy |

| d. Low maintenance cost, long service life |

e. Multiple configurations are available |

5. Our Service

| a. We are the direct factory with good price and fast lead time. |

| b. Professional design team work with you. |

| s. Professional QC team to guarantee the high quality. |

| d. Providing OEM & ODM service. |

6. Production Line