Lingman Machinery Technology (Changzhou) Co., Ltd. |

|

Verified Suppliers

|

|

1. Description

Dense, light aluminum alloy, low inertia, and light weight are the obvious features of our hydraulic cylinder. So based on these characteristics, it can reduce the load on the machine spindle. The solid hydraulic cylinder can continuously rotate and balance at high speed. All the internal parts are imported from origin. Except standard type, high pressure type, long stroke type, and large bore type all can be provided according to your requirements.

The hydraulic cylinder has a simple structure and reliable work. When it is used to achieve reciprocating motion, the deceleration device can be eliminated, and there is no transmission gap, and the motion is stable. Therefore, it is widely used in various mechanical hydraulic systems.

The hydraulic cylinder shows its stability and reduces the mechanical load. So it is the priority for CNC lathe machines.

2. Performance Parameters

Model number | RH-150 |

Push side | 173.6cm2 |

Pull side | 157.7cm2 |

Stroke | 30mm |

Max. numbers of revolutions | 4000 r.p.m |

Max.working pressure | 4Mpa |

Weight | 11.5KG |

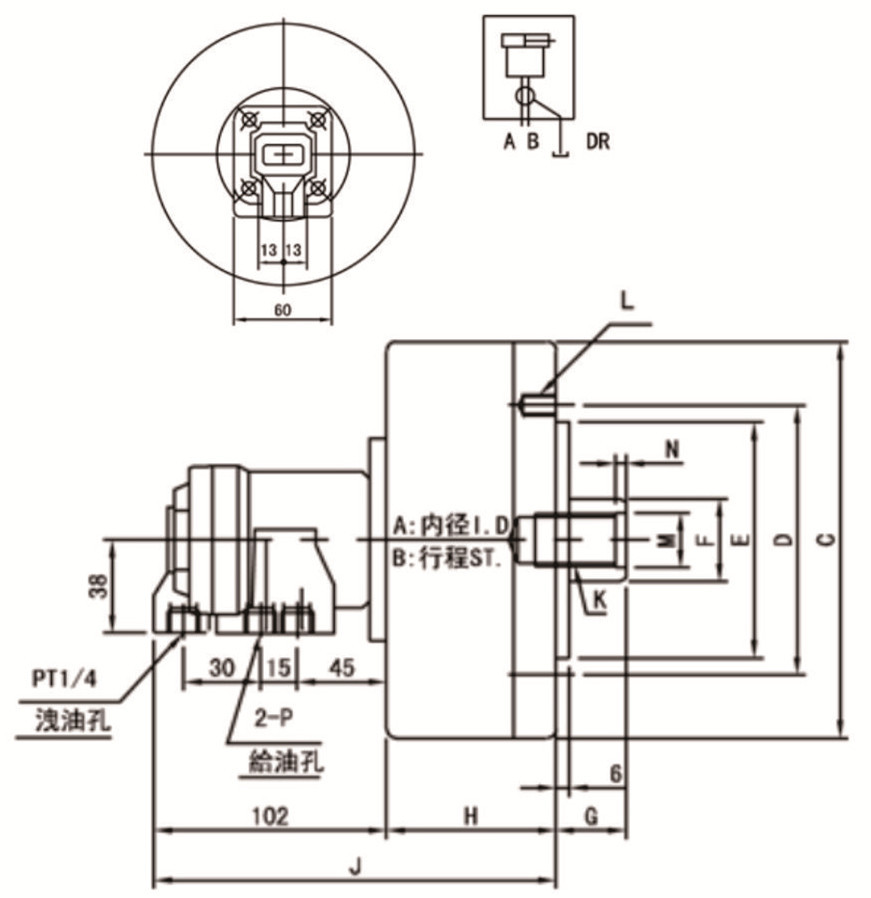

3. Dimensions

| Specifications | A | B | C | D | E | F | G | H | J | K | L | MH8 | N | 2-P |

| RH-150 | 150 | 30 | 190 | 130 | 110 | 45 | 25-55 | 105 | 206 | M30X45 | 6-M12X24 | 31 | 5 | PT3/8 |

4. Advantages

| a. Full stroke design |

| b. Wide range of applications, diversification of processing profiles |

| c. High repetitive positioning accuracy |

| d. Low maintenance cost, long service life |

e. Multiple configurations are available |

5. Production Line

6. Our Service

| a. We are the direct factory with good price and fast lead time. |

| b. Professional design team work with you. |

| s. Professional QC team to guarantee the high quality. |

| d. Providing OEM & ODM service. |

7. FAQ

Q:What's the OEM serivce of OREE LASER?

A:1. Customized and OEM orders are welcome if you need;

2. All the OEM services are free, customer only need to provide us

with your logo drawing,

function requirements, colors etc;

3. No MOQ required.