Lingman Machinery Technology (Changzhou) Co., Ltd. |

|

Verified Suppliers

|

|

1. Description

The connecting between the chuck and main shaft complies with the national standard(short cylinder connecting mode), so users only need to prepare right connection flange compatible with the machine tool and chuck instead of changing the machine tool structure during installation.

The whole installation process is quite easy. The chuck body is the

cylinder, with piston and inverted valve inside to achieve

super-long time pressure-keeping function (more than 24 hours). The

clamping and loosing movement is achieved by rotary air inlet at

the side. The machine will not work before cutting off the gas

supply.

The chuck boasts advantages of less weight, big hole diameter, high

stroke and high rotating speed, which is applicable for lathe, pipe

thread machine tool and welding equipment.

2. Performance Parameters

Model number | BK130TQ |

Claw stroke/diameter | 3.7mm |

Max. clamping force | 15KN |

Allowable pressure | 0.4-0.9Mpa |

Limit speed | 2600r/m |

Clamping range | 2-130mm |

Net weight | 11KG |

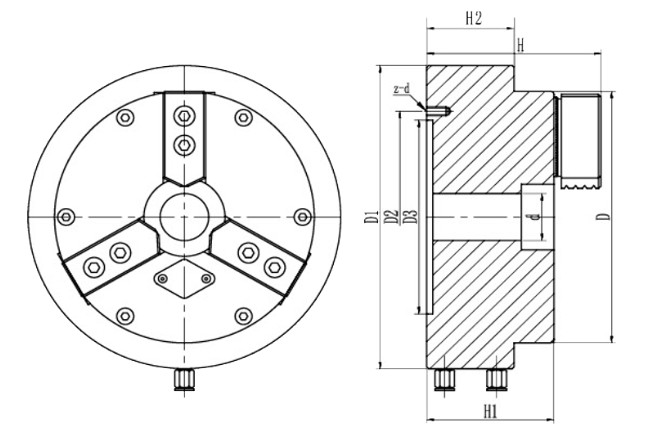

3. Dimensions

| Specifications | D | D1 | D2 | D3 | d | H | H1 | H2 | z-d |

| BK130TQ | 135 | 175 | 108 | 95 | 25 | 132 | 101 | 66 | 3-M8 |

4. Advantages

| a. Full stroke design |

| b. Wide range of applications, diversification of processing profiles |

| c. High repetitive positioning accuracy |

| d. Low maintenance cost, long service life |

e. Multiple configurations are available |

5. Production Line

6. Our Service

| a. We are the direct factory with good price and fast lead time. |

| b. Professional design team work with you. |

| s. Professional QC team to guarantee the high quality. |

| d. Providing OEM & ODM service. |