Henan Lanphan Industry Co.,Ltd |

|

Verified Suppliers

|

|

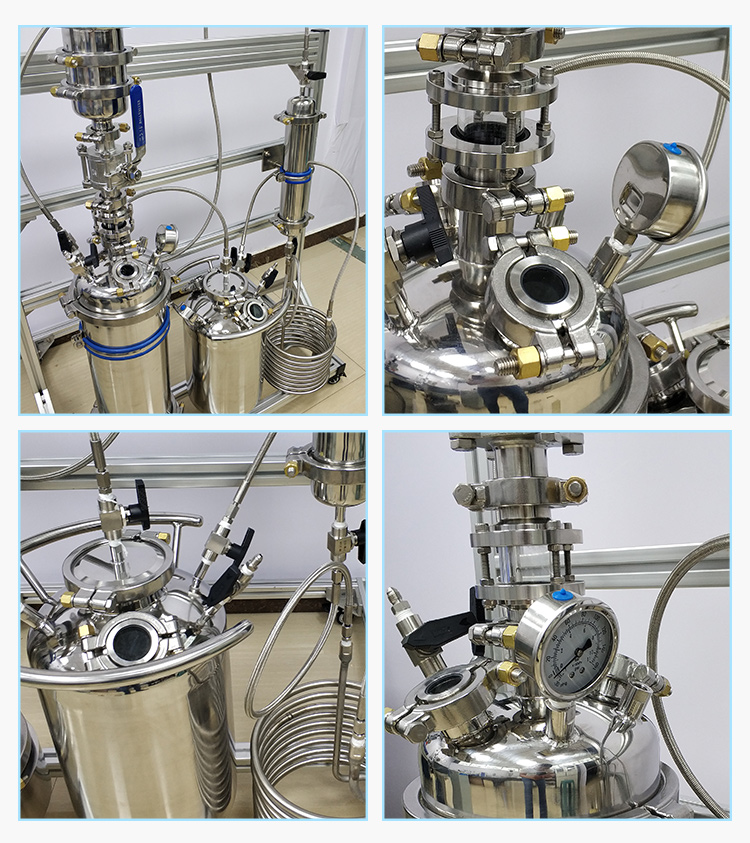

Flange Seal SS304 Closed Loop Extraction Machine

Product Parameter

| polish | mirror polish |

| seal | Flange,mesh gasket |

| Capacity | 1LB |

| Stainless construction | SS304 |

It’s well-known that closed loop extractors are widely used for the extraction and concentration of substances in chemical, biochemical, industrial fields and other fields. It’s especially suitable for the process of food , perfume and othe beauty products. The reasons can be concluded as follows. Firstly, it is safer because of the closed-loop extraction setup. Secondly, it’s energy-saving due to the materials can be reused. Thirdly, it possesses a higher efficiency and better quality, which can separate various substances very quickly and produce the pure extracted solvents.

There are several types of closed loop extractors. In terms of ways of solvent injection, closed loop extractors can be classified into the top filled closed loop extractors and the bi-directional closed loop extractors. In terms of ways of solvent movement, closed loop extractors can be classified into the passive closed loop extractors and the active closed loop extractors.

When the closed loop extractors are used to extract and concentrate substances, the ethanol is usually chosen as the washing solvent. The working process of closed loop extractors can be concluded as follows. Firstly, users need to put the sample materials into the closed loop extractor from the top. The user places the hemp in the top fill inlet, then the solvent washes the hemp in the column of material and then collects the oil as it passes through the material. Secondly, after users put the sample materials into the top, the materials will be washed by special liquid to extract the pointed solvents from the sample materials. The solvent containing the oil will be collected into the collection chamber below the column of material. After the solvent containing the oil arrives the collecting tank, the oil will stay in the collecting tank and the washing solvent will be transferred back into main reacting column to be reused, which proves the closed loop extractor is energy-saving.

The equipment primarily consists of three parts: a solvent tank, a material column and a receiving foundation. Some upgraded versions add a dewaxing column as the fourth part, or equip the material column with a dewaxing structure directly.