Henan Lanphan Industry Co.,Ltd |

|

Verified Suppliers

|

|

Wiped Film Distillation Equipment Electric Vacuum Oil Molecular System

As a new kind of separation method, the Wiped Film Distillation Equipment varies from the normal distillation.

It makes fully use of difference in the free path of molecular motion of different materials to realize the separation. Hence, the molecular can be operated far below the boiling point.

This is a kind of process of distilling and purifying the heat sensitive material or high boiling point material making use of the difference of material molecular movement free path in high vacuum degree.

The Wiped Film Distillation Equipment is mainly used in chemical, pharmaceutical, petrochemical, spices, plastics, oil and other fields.

Features and Advantages

Q: Do you accept custom model Wiped Film Distillation Equipment except for the models in your parameter sheet?

A: The models in the sheet can be adjustable according to customer needs, and the custom model is available as well.

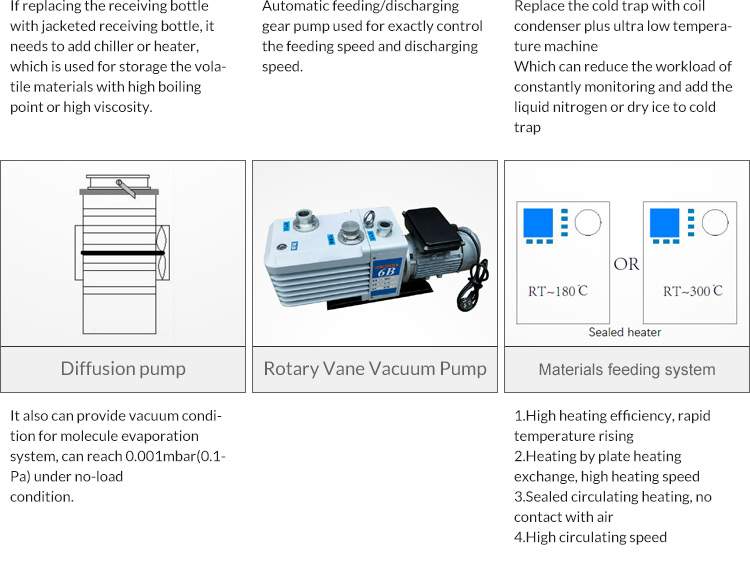

Q: What is the maximum vacuum degree the equipment can reach?

A: The common one can reach 0.05mbar. The one equipped with a secondary diffusion pump can be up to 0.001mbar.

Q: What is the relationship among the rotary evaporator, short-path distillation and Wiped Film Distillation Equipment?

A: The rotary evaporator--used to handle materials with low boiling point.

Short-path distillation--used to handle materials with high boiling point.

Wiped Film Distillation Equipment--used to handle materials with high boiling point. It can replace the short-path distillation as it is more efficient than the short-path distillation and can get purer products.

Wiped Film Distillation Parameters

| Item | Effective evaporation area(m²) | condensation area(m²) | Evaporator inside diameter(mm) | constant pressure funnel volume(L) | Handing capacity(KG/H) | Motor power(W) | Max. rotary speed(RPM) |

| LMD-60 | 0.05 | 0.1 | 60 | 0.5 | 0.1-2.0 | 120 | 450 |

| LMD-80 | 0.1 | 0.15 | 80 | 1 | 0.3-4.0 | 120 | 450 |

| LMD-100 | 0.15 | 0.2 | 100 | 1 | 0.5-5.0 | 120 | 450 |

| LMD-150 | 0.25 | 0.4 | 150 | 2 | 1.0-8.0 | 120 | 450 |

| LMD-200 | 0.35 | 0.5 | 190 | 2 | 1.5-10.0 | 200 | 300 |

| LMD-300 | 0.5 | 0.65 | 220 | 5 | 2.0-15.0 | 200 | 300 |

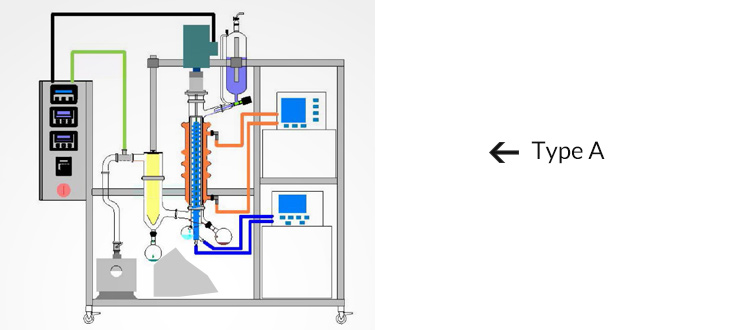

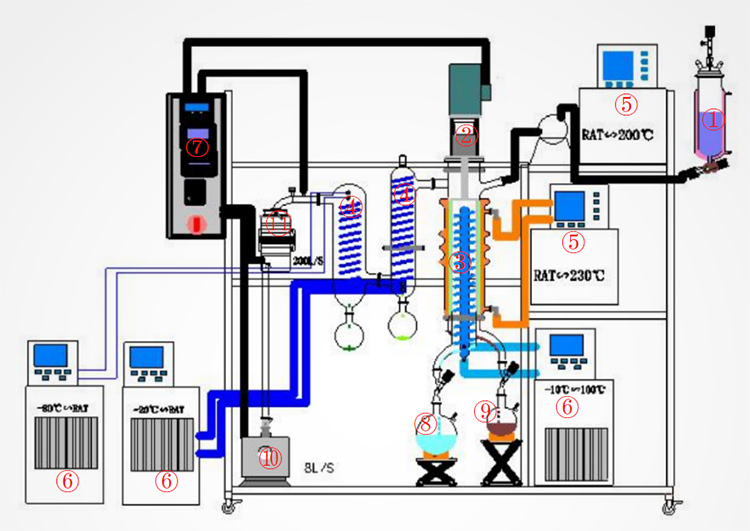

1. Feeding pot

2. Magnetic coupling drives stirring

3. Jacketed evaporator(with condenser inside)

4. condenser

5. Circulating heater(work with jacketed evaporator)

6. Heating and cooling circulator (work with internal condenser)

7. Controlling system(show vacuum degree, control and

display 2.rotary speed)

8. Distillate Receiving bottle(low boiling point)

8. Residue Receiving bottle(high boiling point)

10. Rotary vane vacuum pump

11. Diffusion pump

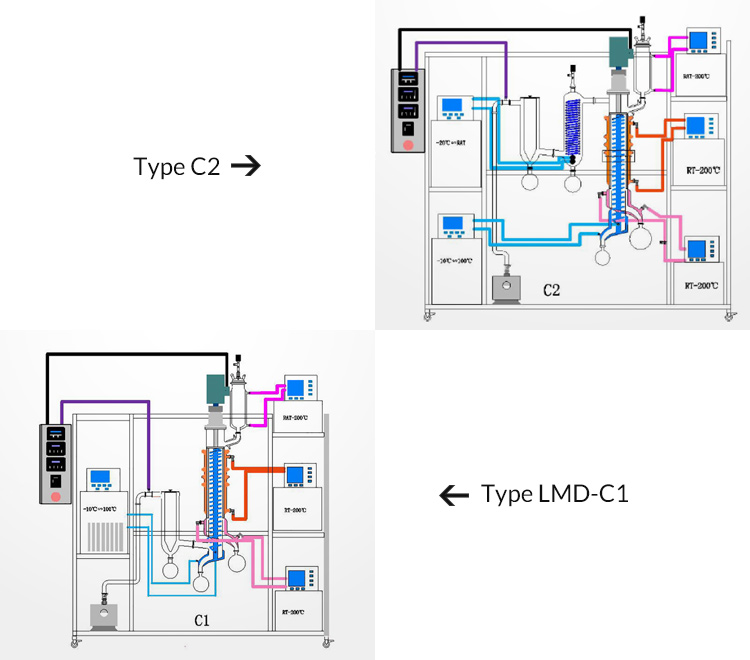

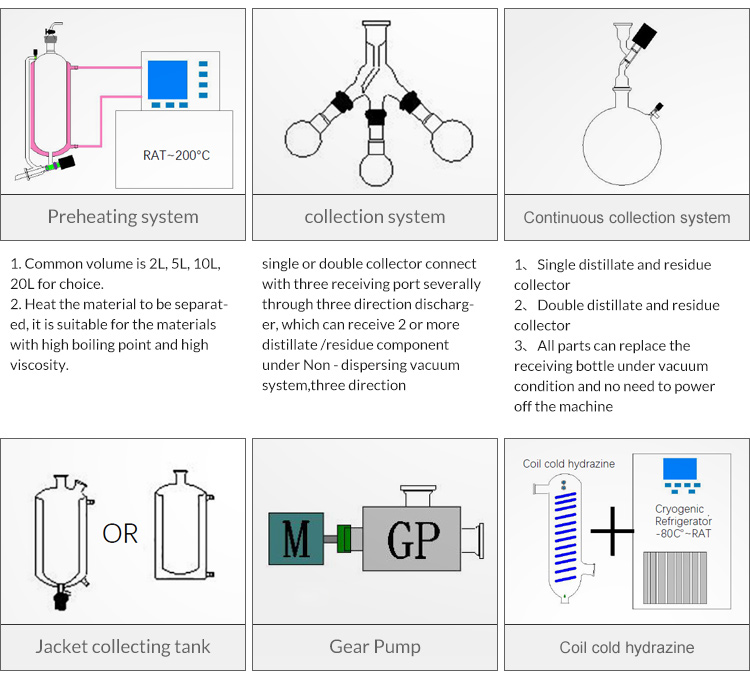

SERIES PRODUCTS