Henan Lanphan Industry Co.,Ltd |

|

Verified Suppliers

|

|

Vacuum freeze drying technology, also known as sublimation drying, is a method of pre-freezing water-containing substances and sublimating the water under vacuum. The original biological and chemical properties of freeze-dried products remain basically unchanged and are easy to store for a long time. After adding water, it can be restored to the state before freeze-drying and maintain its original biochemical characteristics. Therefore, vacuum freeze-drying technology is widely used in medicine, food, chemical industry, biological products and other fields.

| Product Model | HFD-8 |

| Freeze-dried area | 1 M2 |

| Processing capacity | 10-12 kg/batch |

| Tray quantity | 8pcs |

| Tray size(mm) | 265*435*25 |

| Spacing between partitions | 40mm |

| Power(W) | 2500 |

| Ultimate vacuum | 15Pa |

| Cold trap temperature | ≤-40ºC |

| Temperature probe | independent probe |

| Compressor | French Danfoss brand |

| Frame | Iron frame + Plastic spraying |

Main features

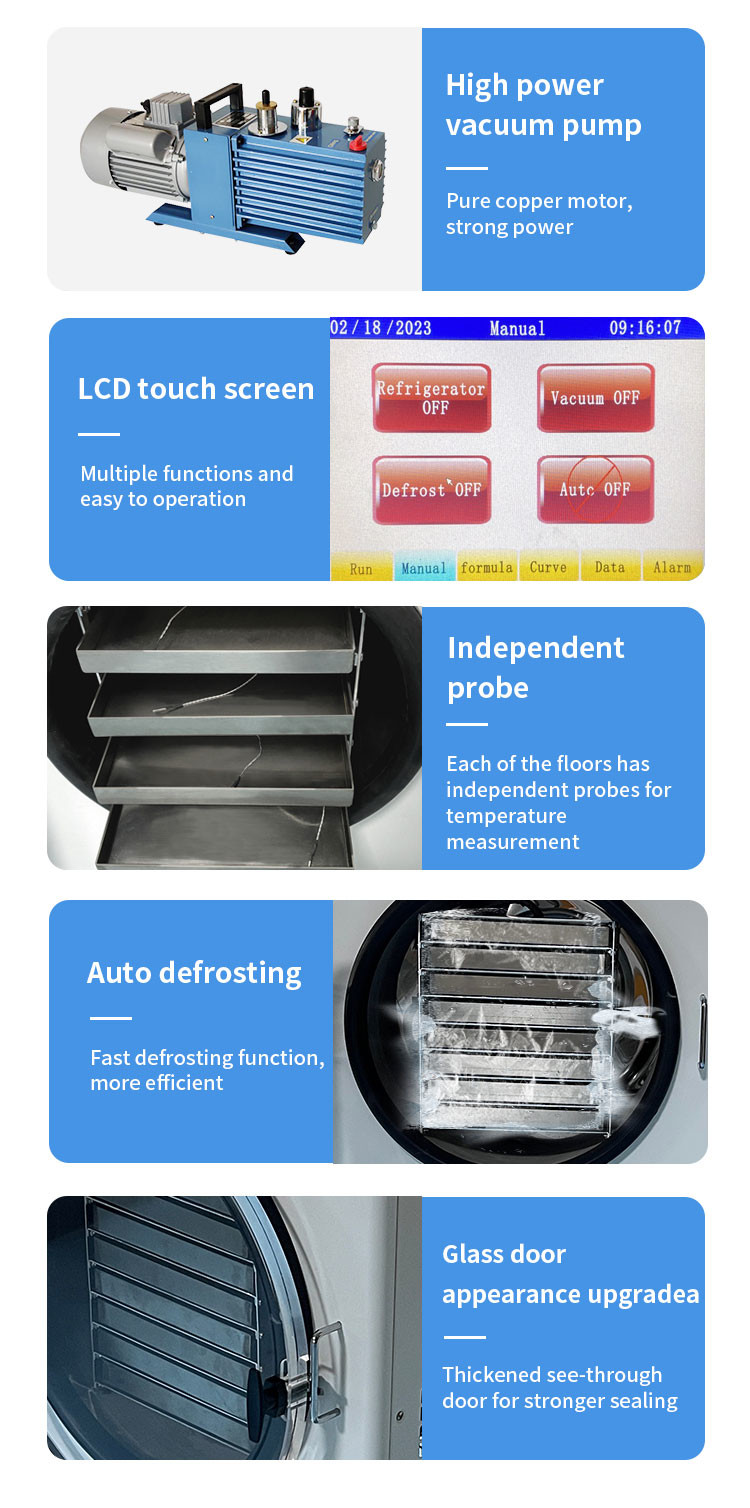

High power vacuum pump

Pure copper motor, strong power

LCD touch screen

Multiple functions and easy to operation

Independent probe

Each of the floors has independent probes for temperature

measurement

Auto defrosting

Fast defrosting function, more efficient

Glass doorappearance upgradea

Thickened see-through door for stronger sealing

Vacuum freeze-drying is one of the most gentle ways to dry. It is

based on the sublimation principle, that is, the solid phase

directly into the gas phase of this physical phenomenon. The

freeze-dried material is placed in a vacuum drying chamber for

drying, and the water vapor produced by the cold trap is condensed

to form ice, so as to achieve the purpose of eliminating water

vapor. Vacuum pump is used to discharge the air in the drying room,

not including water vapor.

The baffle plate is provided with a heating device, and the heat is

transferred to the material through the conduction function to

provide the energy needed for sublimation. When the free water in

the material is sublimated, the internal bound water can also be

removed from the material at a very low vacuum. This drying process

is considered to be the last stage of drying, analytical drying.

In-Sale Service

With supervision from the source of products, the qualified rate of

raw materials entering the factory can reach 100%;

Whole manufacturing process are in strict accordance with promised

procedure requirements, product qualified rate can reach 100%;

Provide product's inspection record of key junctures to customers;

Provide production schedule photos to customers at regular

intervals;

Package and transport of products are in strict accordance with the

export standard;

Provide transportation schedule information to clients timely.