Henan Lanphan Industry Co.,Ltd |

|

Verified Suppliers

|

|

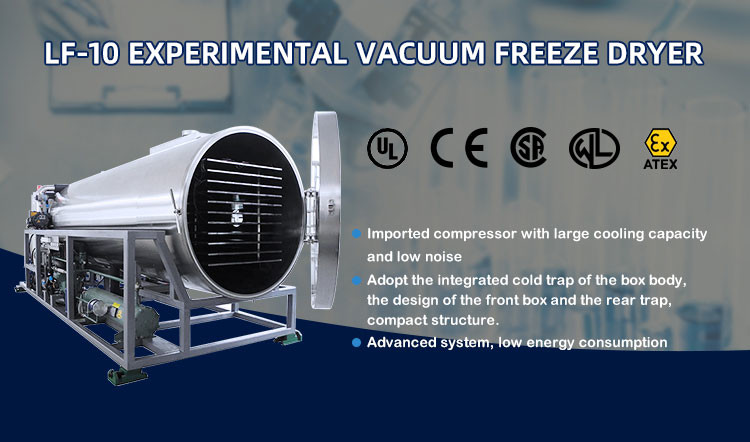

Commercial Industrial Large Lyophilizer Vacuum Freeze Drying Machine For Food Vegetable

industrial freeze dryer parameter

| Effective trays square | 10.01㎡ |

| Condenser capacity kg/batch | 100kg/batch |

| Equipment dimensions | Circular chamber,3800*1400*2000mm(L*W*H) |

| Trays dimension | 1300*550*30mm(according to the shelf,can be design and change) |

| Nr Trays | 14pcs(if dimension change,it will change) |

| Installed Power KW | 22.25KW,but will not running all machines all the time |

| Power Voltage | 380V/50HZ |

| Colling Water(Cooling tower use) | about 11.7m³/hr(Recycling,<30℃) |

industrial freeze dryer features

1. Working Principle: Industrial freeze dryers utilize two key steps—freezing and vacuum—to achieve the drying process. Firstly, the substance is frozen into a solid state, and then heat is applied in a vacuum environment. This causes the frozen moisture to transition directly from a solid to vapor state, bypassing the liquid phase, thus achieving rapid drying.

2. Application Fields: Industrial freeze dryers play a vital role across various industries. In the food sector, they are employed to create freeze-dried foods that retain nutritional content, taste, and texture. In pharmaceuticals, they produce stable powdered drugs, extending their shelf life. Furthermore, they are used for producing biologics, enzymes, cell cultures, and more.

3. Industrial Scale: Industrial freeze dryers typically come with larger drying capacities, suitable for large-scale production. Different models offer varying drying capacities and production capabilities to meet specific needs.

4. Temperature and Pressure Control: The equipment is equipped with precise temperature and pressure control systems to ensure optimal conditions during the drying process. This aids in preserving the quality and activity of the products.

5. Operation and Monitoring: Industrial freeze dryers often incorporate advanced automation and monitoring systems, capable of tracking and recording various parameters of the drying process, ensuring controlled and reproducible operations.

6. Product Quality: The freeze-drying process effectively removes moisture from the product, preventing the growth of microorganisms and enzymes, thereby maintaining the long-term stability and activity of the product.

industrial freeze dryer introduction

An industrial freeze dryer is a specialized equipment used for preparing dried products. It finds wide applications in industries such as food, pharmaceuticals, chemical engineering, biotechnology, etc., to convert liquid or semi-solid substances into dried powders or solid forms through a process involving freezing and vacuum drying. Here is a brief introduction to an industrial freeze dryer.