Jiangsu Jinwang Intelligent Sci-Tech Co., Ltd |

|

Verified Suppliers

|

|

25KG Intelligent ECO Pouch Packaging Machine

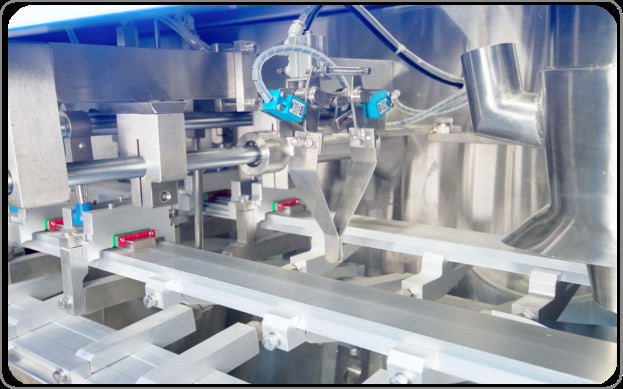

This line consists of weighing machine -bag supplying unit -heat sealing and sewing machine -bag shaping machine -check weight and removal mahcine -stacking machine -winding machine -out of the library unit .It is suitable for M-bag and pillow type bag. The machinery uses the servo driving system instead of the cylinder components to ensure the accuracy. The line is with stable performance and high running speed.It reduces the labor effectively.

Technical parameters

| 1 | Production capacity | 40-60 pack / sub * Actual capacity depends on the packaging material |

| 2 | Suitable for the bag type | W100-215mm;L140-300mm |

| 3 | Packaging capacity | The ≤ 500g * actual packaging volume is determined by the specific weight of the material and the package size |

| 4 | Fill accuracy. | ± 1% (depending on the material condition) |

| 5 | Power Supply / Power | Three-phase AC380V,50Hz/3.5KW |

| 6 | Air source pressure | 0.5-0.7MPa |

| 7 | Equipment dimensions | 3373×2356×2544mm(L×W×H) |

| 8 | Dust removal pipe diameter. | Φ98mm |

| 9 | Complete machine weight | Approximately 3,500 Kg |

Equipment dimension drawing:

Good results.

1, capacity improvement: the equipment mainly optimizes the cam operation curve based on the original equipment and improves the processing process twice.

Surface correction, stable action line, improve production capacity (Increase by 10% -20% based on the original production capacity)

2,High accuracy: using Spanish cam technology, camams generally use internal cam, no running position, and high operation accuracy

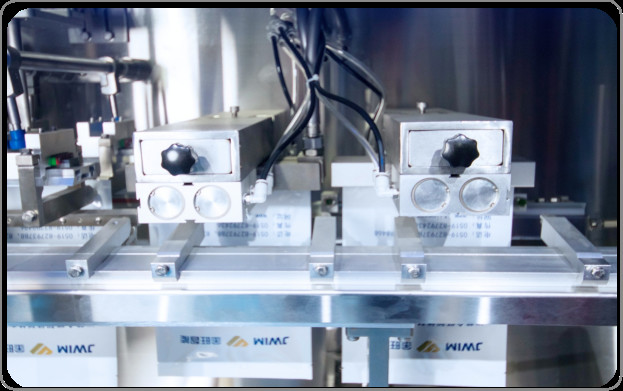

3, easy to maintain: quick demolition type hot block structure, convenient for manual maintenance and cleaning, save time and effort, to ensure efficient operation

4, province cost: unique open bag detection function

Electrical configuration

| No ial | First name | Product Card |

1 | Programmable controller CPU | Schneider, Schneider |

| 2 | Touch-screen | Schneider, Schneider |

| 3 | Converconverter | Schneider, Schneider |

4 |

Servo system | Schneider, Schneider |

| 5 | Approach sensor | Sick Schancecker |

| 6 | Switch on the power supply | Schneider, Schneider. |

| 7 | Vacuum generator. | SMC |

| 8 | Heat fan. | SUNON Completion permit. |

| 9 | Encoder. | OMRON The Omron. |

| 10 | Button. | Schneider, Schneider |

| 11 | Circuit breaker | Schneider, Schneider |

| 12 | Pressure switch | SMC |