Jiangsu Jinwang Intelligent Sci-Tech Co., Ltd |

|

Verified Suppliers

|

|

The GD6-300 returns to the bag packing machine

General information:

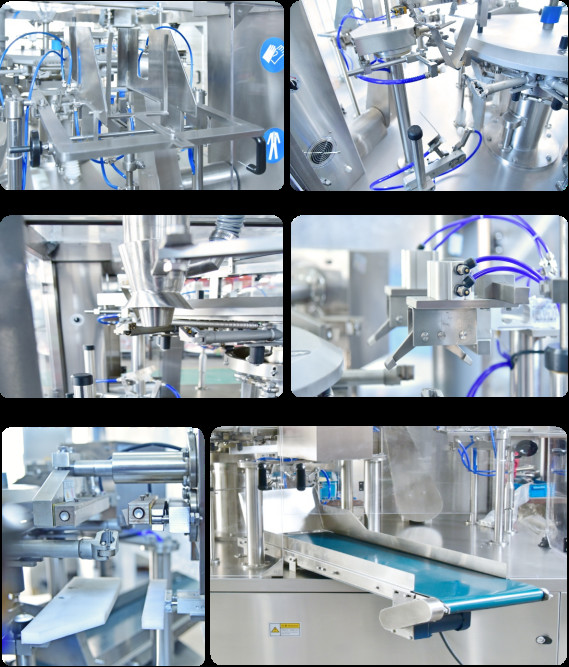

The machine is a rotary structure, six positions, a wide range of packaging, can package liquid, powder, particles, solid materials, only need to choose different metering and filling devices according to different materials. The equipment can quickly change the bag specifications, and the width of the automatic bag device can be easily adjusted by adjusting the handle; the standard detection equipment can detect that the machine without the packing device and the bag is not opened, so as to avoid waste of packing materials and raw materials.

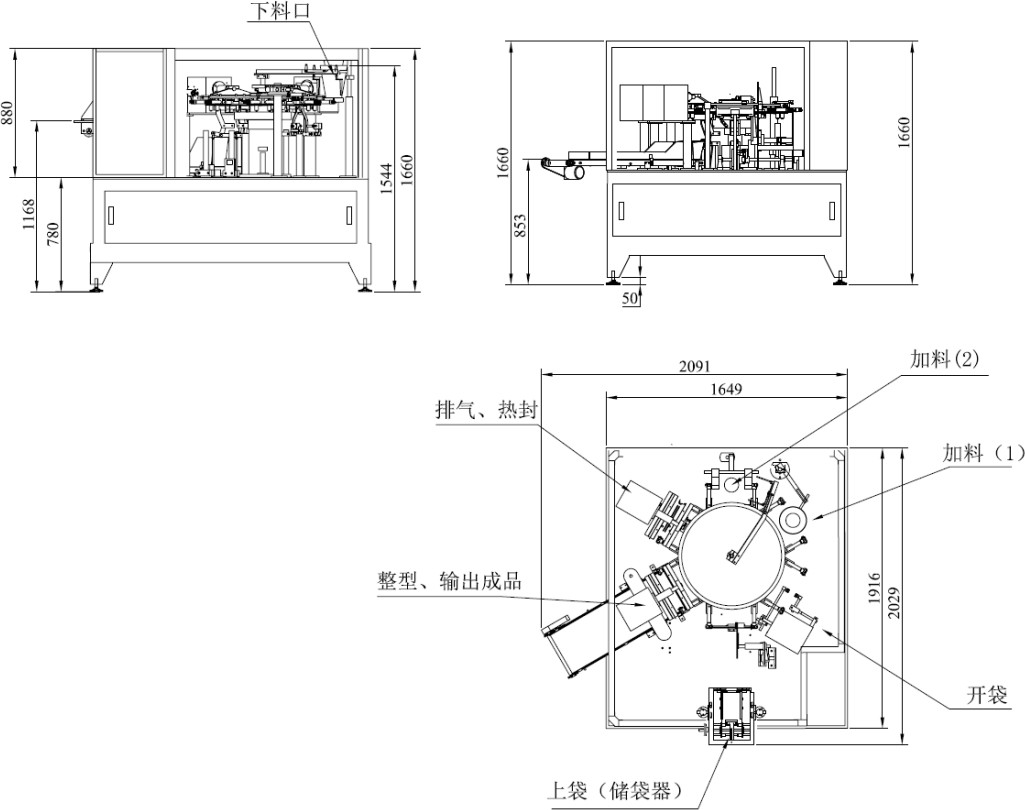

Technical parameters:

| 1 | Production capacity | 10-15 Package / sub * Actual capacity depends on the packaging material |

| 2 | Bag bag size | W200-300mm;L200-380mm. |

| 3 | Suitable for the bag type | Routine bags, self-standing bags; * Zip bag to be customized; M bag with back cover bag to be tested first |

| 4 | Packaging capacity | The ≤ 1000g * is determined by the material weight and package size |

| 5 | Fill accuracy | ± 1% (depending on the material condition) |

| 6 | Power Supply / Power | Three-phase AC380V,50Hz/4KW |

| 7 | Air source pressure | 0.5-0.7MPa. |

| 8 | Equipment dimensions | 2029 × 2091 × 1660mm (L × W × H) |

| 9 | Complete machine weight | About 1,700 Kg |

Equipment dimension drawing:

Equipment advantages:

1,The integrated design of whole machine replaces the traditional manual packaging, realizes the automation of product packaging and production, improves the production efficiency, and greatly reduces the product cost. The complete set of equipment can be operated alone by one person, greatly reducing the labor cost

2, based on the years of experience, using a stable process and driving structure to ensure the packaging effect.

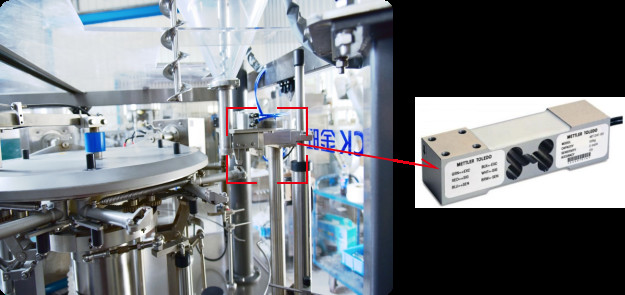

3, adopts the secondary filling mode, the first time for the large dose preliminary filling, to ensure the speed of the whole machine; the second filling with the American Metletoli multiple weighing sensor weighing and filling, to ensure the filling accuracy. (This function is optional)

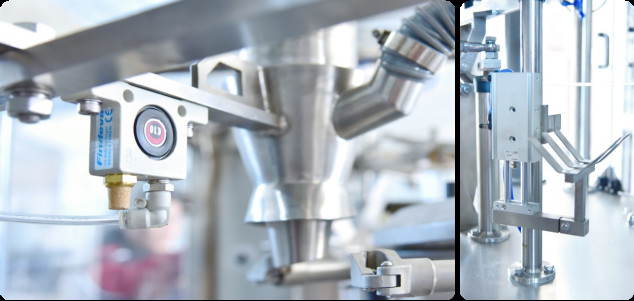

4, adds the vibrator at the characteristics of the powder, which is more smooth without blocking. Fill the bottom solid mechanism, the bag material is more substantial.

5, falling material detection device. No bags without falling materials, empty bags are not sealed, to reduce the waste of materials and materials and polluting equipment.

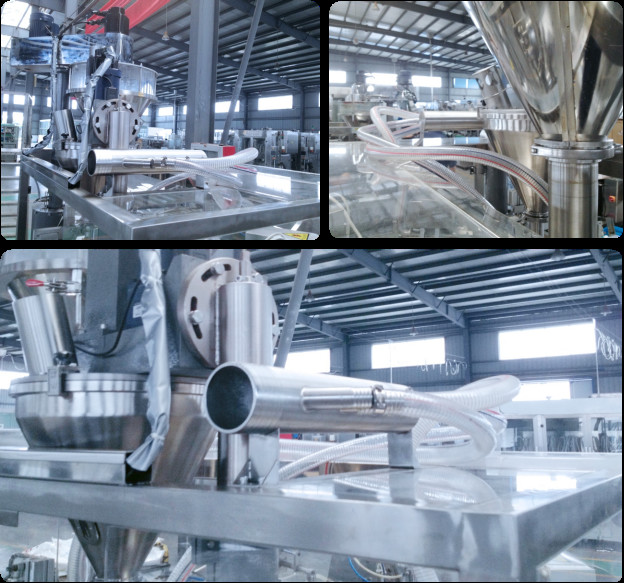

6, packaging counter is of food grade 304 stainless steel, 2mm, mirror plate and electrical box is 304 stainless steel 2mm.Upper bag, open bag, sealing and clamping are of 304 stainless steel.

7,The drive part cam is 45 # forging material, heat treatment hardness ≥ HR50 degree, 45 # grinding shaft, smooth surface and wear resistance.

8, machine is standard equipped with automatic monitoring system device, can detect air pressure, temperature controller failure, bag mouth opening, to judge the state of the machine, can control the code playing device, filling device, filling device, heat sealing device, whether to move, so as to avoid waste of packaging materials and raw materials, and save production cost.

9, equipment is equipped with dust removal pipeline to connect with engineering exhaust system to reduce dust on production site. (This function is optional)

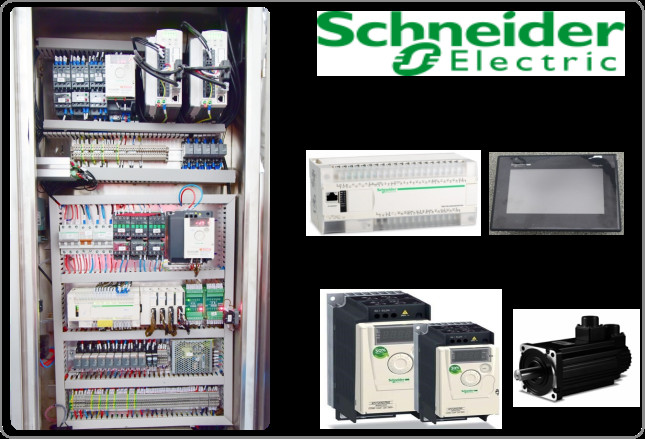

10,The electric control system adopts French Schneider configuration, with integrated electric control system, which is more stable, reliable, safe, green and low energy consumption.

Main configuration of the equipment:

| No ial | First name "Said that." | Product Card |

1 | Programmable controller CPU. | Schneider. Schneider |

| 2 | Touch-screen | Schneider. Schneider |

| 3 | Converconverter | Schneider. Schneider |

4 |

Servo system | Schneider. Schneider |

| 5 | Vacuum pump | BECKER. Baker, Germany |

| 6 | Solenoid valve | SMC. |

| 7 | Cylinder | SMC. |

| 8 | Button | Schneider. Schneider |

| 9 | Circuit breaker | Schneider. Schneider |