CHANGZHOU JKONGMOTOR CO.,LTD |

|

Verified Suppliers

|

|

| Item | Specifications |

| Step Angle | 1.8° |

| Temperature Rise | 80℃max |

| Ambient Temperature | -20℃~+50℃ |

| Insulation Resistance | 100 MΩ Min. ,500VDC |

| Dielectric Strength | 500VAC for 1minute |

| Shaft Radial Play | 0.02Max. (450g-load) |

| Shaft Axial Play | 0.08Max. (450g-load) |

| Max. radial force | 28N (20mm from the flange) |

| Max. axial force | 10N |

2.Electrical Specification:

| Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm | Kg | |

| JK42HS34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.2 | 4 | 120 | 34 | 0.22 |

| JK42HS34-0406 | 1.8 | 34 | 0.4 | 24 | 15 | 1.6 | 6 | 120 | 34 | 0.22 |

| JK42HS34-0956 | 1.8 | 34 | 0.95 | 4.2 | 2.5 | 1.6 | 6 | 120 | 34 | 0.22 |

| JK42HS40-0406 | 1.8 | 40 | 0.4 | 30 | 30 | 2.6 | 6 | 150 | 54 | 0.28 |

| JK42HS40-1704 | 1.8 | 40 | 1.7 | 1.5 | 2.3 | 4.2 | 4 | 150 | 54 | 0.28 |

| JK42HS40-1684 | 1.8 | 40 | 1.68 | 1.65 | 3.2 | 3.6 | 4 | 150 | 54 | 0.28 |

| JK42HS40-1206 | 1.8 | 40 | 1.2 | 3 | 2.7 | 2.9 | 6 | 150 | 54 | 0.28 |

| JK42HS48-0406 | 1.8 | 48 | 0.4 | 30 | 25 | 3.1 | 6 | 260 | 68 | 0.35 |

| JK42HS48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 4.4 | 4 | 260 | 68 | 0.35 |

| JK42HS48-1206 | 1.8 | 48 | 1.2 | 3.3 | 2.8 | 3.17 | 6 | 260 | 68 | 0.35 |

| JK42HS60-0406 | 1.8 | 60 | 0.4 | 30 | 39 | 6.5 | 6 | 280 | 102 | 0.5 |

| JK42HS60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.5 |

| JK42HS60-1206 | 1.8 | 60 | 1.2 | 6 | 7 | 5.6 | 6 | 280 | 102 | 0.5 |

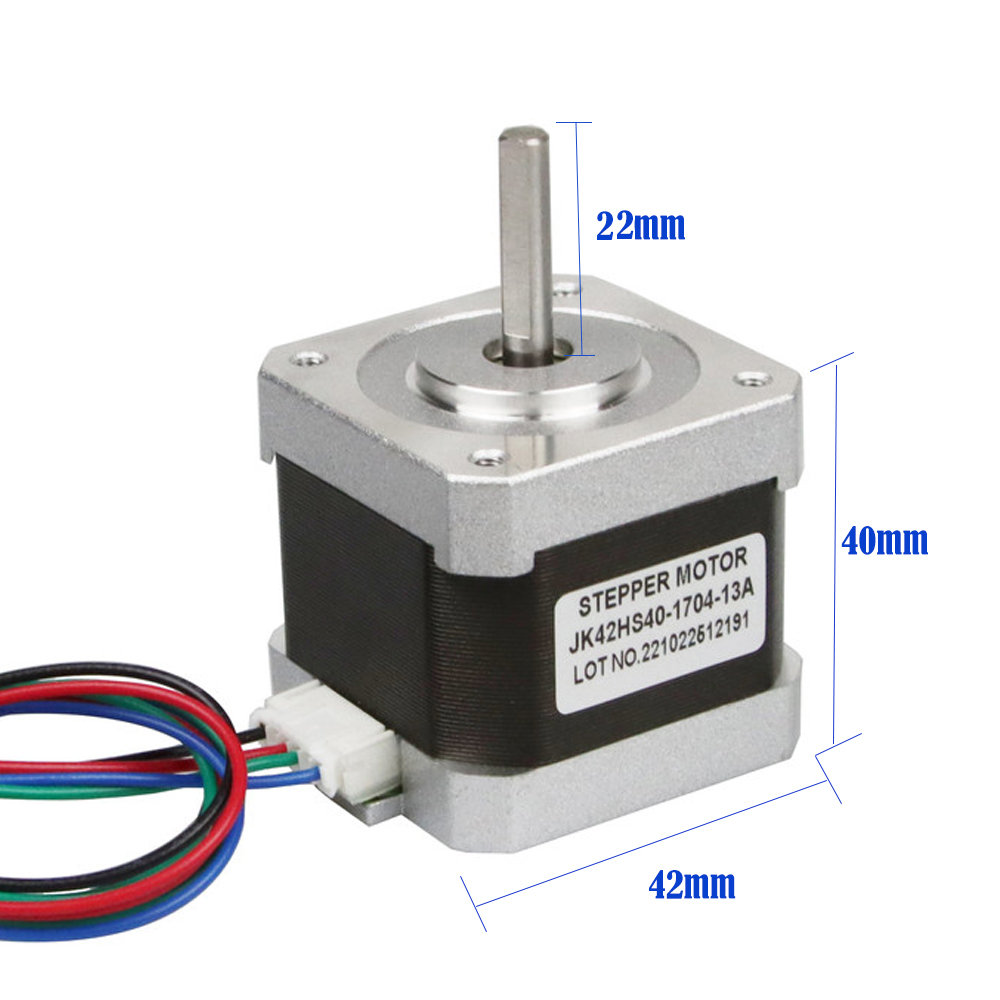

3.Dimensions: (Unit=mm)

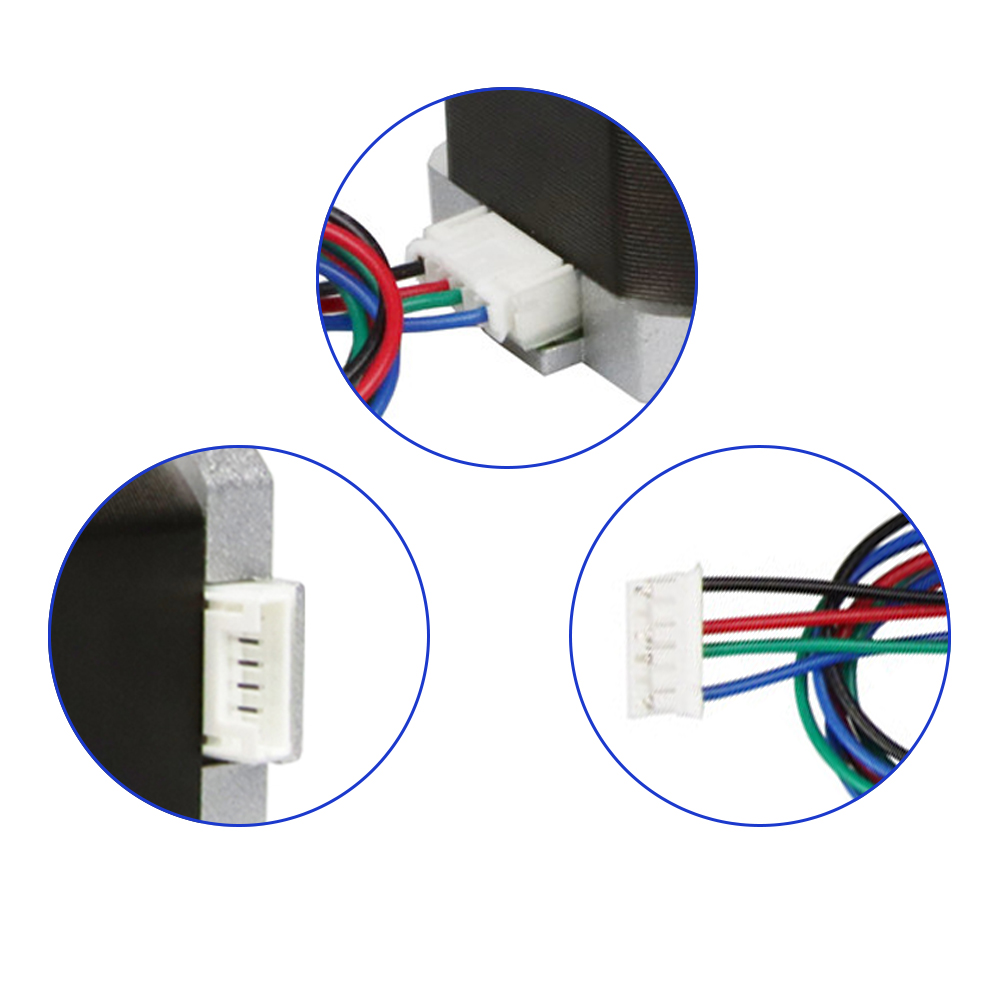

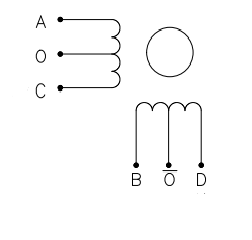

4.Wiring Diagram:

5.Customized

Advantages

What is a stepper motor used for?

Computer controlled stepper motors are a type of motion-control positioning system. They are typically digitally controlled as part of an open loop system for use in holding or positioning applications.

In the field of lasers and optics they are frequently used in precision positioning equipment such as linear actuators, linear stages, rotation stages, goniometers, and mirror mounts. Other uses are in packaging machinery, and positioning of valve pilot stages for fluid control systems.

Commercially, stepper motors are used in floppy disk drives, flatbed scanners, computer printers, plotters, slot machines, image scanners, compact disc drives, intelligent lighting, camera lenses, CNC machines and, more recently, in 3D printers.