CHANGZHOU JKONGMOTOR CO.,LTD |

|

Verified Suppliers

|

|

17HS4401 40mm Nema 17 Stepper Motor 1.7A 12V 42Ncm (59.49oz.In) Used For CNC 3D Printer XYZ

A hybrid stepper motor is a combination of the variable reluctance and permanent magnet type motors. The rotor of a hybrid stepper motor is axially magnetized like a permanent magnet stepper motor, and the stator is electromagnetically energized like a variable reluctance stepper motor.

Compared with servomotors, hybrid steppers have the advantage of rugged, simple construction; reliability with little maintenance; high torque at low speeds; and no need for position or velocity feedback devices.

A typical small step angle of a hybrid stepper is 1.8°(sometimes 0.9°). This corresponds to 200 (or 400) steps per revolution. To obtain a higher precision a reduction mechanism or gearbox can be used.

Due to the availability of lower step resolutions of 0.9°, 1.8°, or 3.6°, the standard being 1.8°. They exhibit high static and dynamic torque characteristics (response for starting, stopping, and reversing). Hence, hybrid stepper motors are used in various industrial and domestic applications like, Robotics.

1.Genaral Specification of nema 17 stepper motors:

| Name | nema 17 step motor |

| Model | JK42HS40-1704-13A |

| Motor Type | hybrid stepping motor |

| Rated Voltage | 2.55V |

| Holding Torque | 42Ncm (59.49oz.in) |

| Step Angle | 1.8 degree |

| Current | 1.7A |

| Shaft | 5mm D-cut shaft |

| Usage | Engraving machines, laser machines, CNC machine tools, textile and garment machinery, medical equipment, measuring equipment, electronic processing equipment, packaging machinery and other various automation equipment and instruments. |

2.Electrical Specification of stepping motor (1.8 degree):

| Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass | |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | ||

| JK42HS25-0404 | 1.8 | 25 | 0.4 | 24 | 36 | 1.8 | 4 | 75 | 20 | 0.15 | |

| JK42HS28-0504 | 1.8 | 28 | 0.5 | 20 | 21 | 1.5 | 4 | 85 | 24 | 0.22 | |

| JK42HS34-1334 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.2 | 4 | 120 | 34 | 0.22 | |

| JK42HS34-0406 | 1.8 | 34 | 0.4 | 24 | 15 | 1.6 | 6 | 120 | 34 | 0.22 | |

| JK42HS34-0956 | 1.8 | 34 | 0.95 | 4.2 | 2.5 | 1.6 | 6 | 120 | 34 | 0.22 | |

| JK42HS40-0406 | 1.8 | 40 | 0.4 | 30 | 30 | 2.6 | 6 | 150 | 54 | 0.28 | |

| JK42HS40-1684 | 1.8 | 40 | 1.68 | 1.65 | 3.2 | 3.6 | 4 | 150 | 54 | 0.28 | |

| JK42HS40-1206 | 1.8 | 40 | 1.2 | 3 | 2.7 | 2.9 | 6 | 150 | 54 | 0.28 | |

| JK42HS48-0406 | 1.8 | 48 | 0.4 | 30 | 25 | 3.1 | 6 | 260 | 68 | 0.35 | |

| JK42HS48-1684 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 4.4 | 4 | 260 | 68 | 0.35 | |

| JK42HS48-1206 | 1.8 | 48 | 1.2 | 3.3 | 2.8 | 3.17 | 6 | 260 | 68 | 0.35 | |

| JK42HS60-0406 | 1.8 | 60 | 0.4 | 30 | 39 | 6.5 | 6 | 280 | 102 | 0.5 | |

| JK42HS60-1704 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.5 | |

| JK42HS60-1206 | 1.8 | 60 | 1.2 | 6 | 7 | 5.6 | 6 | 280 | 102 | 0.5 | |

3.Electrical Specification of stepping motor (0.9 degree):

| Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

| JK42HM34-1334 | 0.9 | 34 | 1.33 | 2.1 | 4.2 | 2.2 | 4 | 200 | 35 | 0.22 |

| JK42HM34-0316 | 0.9 | 34 | 0.31 | 38.5 | 33 | 1.58 | 6 | 200 | 35 | 0.22 |

| JK42HM34-0956 | 0.9 | 34 | 0.95 | 4.2 | 4.0 | 1.58 | 6 | 200 | 35 | 0.22 |

| JK42HM40-1684 | 0.9 | 40 | 1.68 | 1.65 | 3.2 | 3.3 | 4 | 220 | 54 | 0.28 |

| JK42HM40-0406 | 0.9 | 40 | 0.4 | 30 | 30 | 2.59 | 6 | 220 | 54 | 0.28 |

| JK42HM40-1206 | 0.9 | 40 | 1.2 | 3.3 | 3.4 | 2.59 | 6 | 220 | 54 | 0.28 |

| JK42HM48-1684 | 0.9 | 48 | 1.68 | 1.65 | 4.1 | 4.4 | 4 | 250 | 68 | 0.35 |

| JK42HM48-1206 | 0.9 | 48 | 1.2 | 3.3 | 4 | 3.17 | 6 | 250 | 68 | 0.35 |

| JK42HM48-0406 | 0.9 | 48 | 0.4 | 30 | 38 | 3.17 | 6 | 250 | 68 | 0.35 |

| JK42HM60-1684 | 0.9 | 60 | 1.68 | 1.65 | 5.0 | 5.5 | 4 | 270 | 106 | 0.55 |

4.Electrical Specification of closed loop stepper motor:

| Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

| JK42HS34-1334BED-01 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.6 | 4 | 120 | 34 | 0.22 |

| JK42HS40-1704BED-02 | 1.8 | 40 | 1.7 | 1.5 | 2.3 | 4.2 | 4 | 150 | 54 | 0.28 |

| JK42HS48-1684BED-02 | 1.8 | 48 | 1.68 | 1.65 | 2.8 | 5 | 4 | 260 | 68 | 0.38 |

| JK42HS60-1704BF-ED-01 | 1.8 | 60 | 1.7 | 3 | 6.2 | 7.3 | 4 | 280 | 102 | 0.55 |

5.Electrical Specification of nema 17 brake stepper motor:

| Model No. | Step Angle | Motor Length | Current /Phase | Resistance /Phase | Inductance /Phase | Holding Torque | # of Leads | Detent Torque | Rotor Inertia | Mass |

| ( °) | (L)mm | A | Ω | mH | kg.cm | No. | g.cm | g.cm2 | Kg | |

| JK42HS34-1334BK0.5 | 1.8 | 34 | 1.33 | 2.1 | 2.5 | 2.2 | 4 | 120 | 34 | 0.4 |

| JK42HS40-1684BK0.5 | 1.8 | 40 | 1.68 | 1.65 | 3.2 | 3.6 | 4 | 150 | 54 | 0.46 |

| JK42HS48-2504BK0.5 | 1.8 | 48 | 2.5 | 1.6 | 1.8 | 5.0 | 4 | 260 | 68 | 0.53 |

| JK42HS60-1504BK0.5 | 1.8 | 60 | 1.5 | 4.0 | 6.0 | 7.5 | 4 | 280 | 102 | 0.68 |

6.Electrical Specification of nema 17 linear screw:

| Screw Diameter | Screw Lead | Screw Pitch | Travel per step | Screw Diameter | Screw Lead | Screw Pitch | Travel per step |

| mm | mm | mm | mm | mm | mm | mm | mm |

| Tr5 | 1 | 1 | 0.005 | Tr8 | 8 | 2 | 0.04 |

| 2 | 1 | 0.01 | 10 | 2 | 0.05 | ||

| Tr6 | 2 | 1 | 0.01 | 12 | 2 | 0.06 | |

| 4 | 1 | 0.02 | 14 | 2 | 0.07 | ||

| 6 | 1 | 0.03 | Tr10 | 2 | 2 | 0.01 | |

| 12 | 2 | 0.06 | 3 | 1.5 | 0.015 | ||

| Tr8 | 1 | 1 | 0.005 | 4 | 2 | 0.02 | |

| 2 | 2 | 0.01 | 8 | 2 | 0.04 | ||

| 3 | 1.5 | 0.015 | 10 | 2 | 0.05 | ||

| 4 | 2 | 0.02 | 12 | 2 | 0.06 |

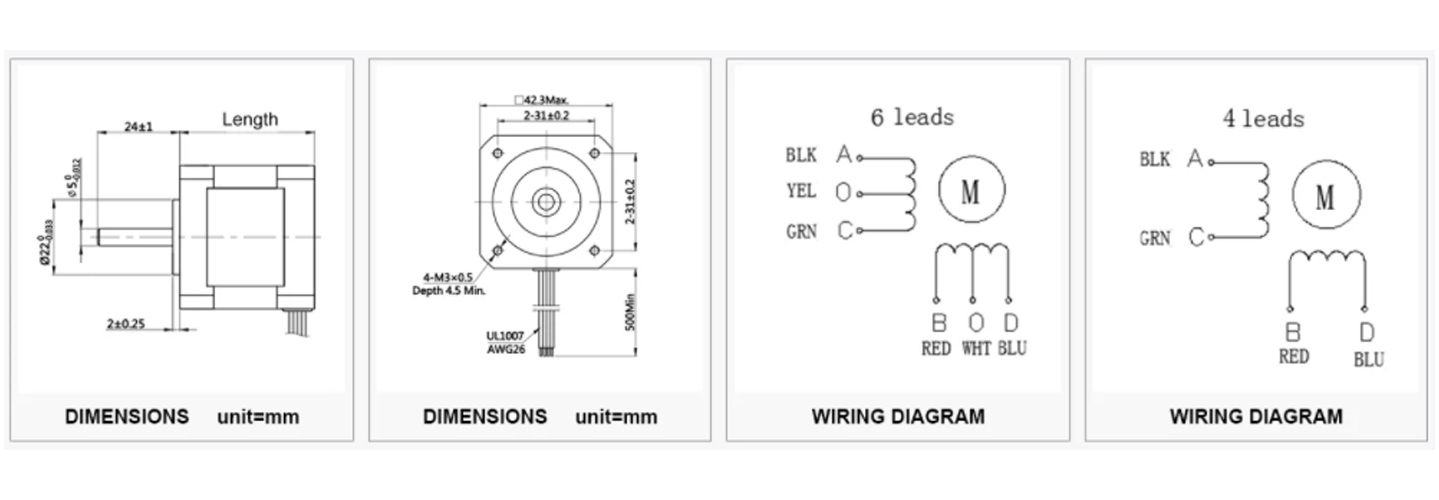

7.Drawing of 42mm step motor:

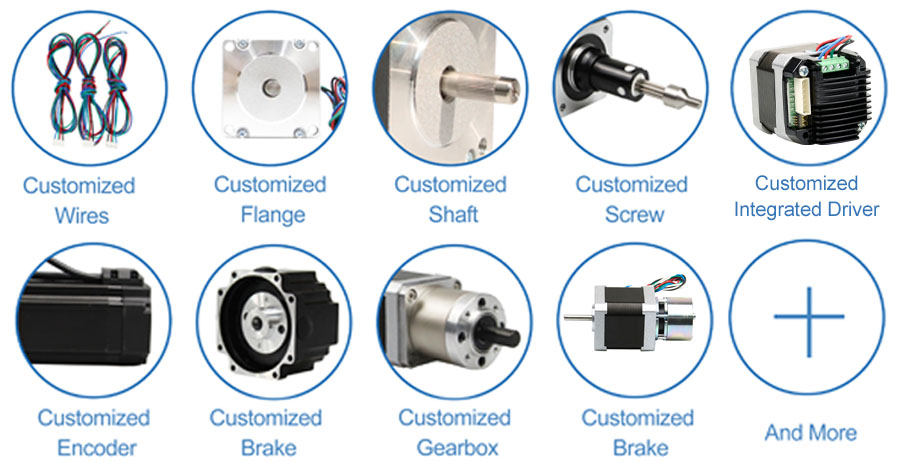

8.Customized design of stepping motor:

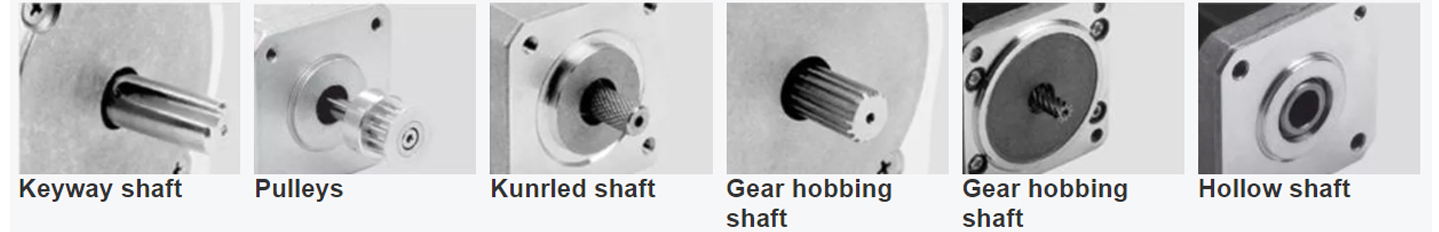

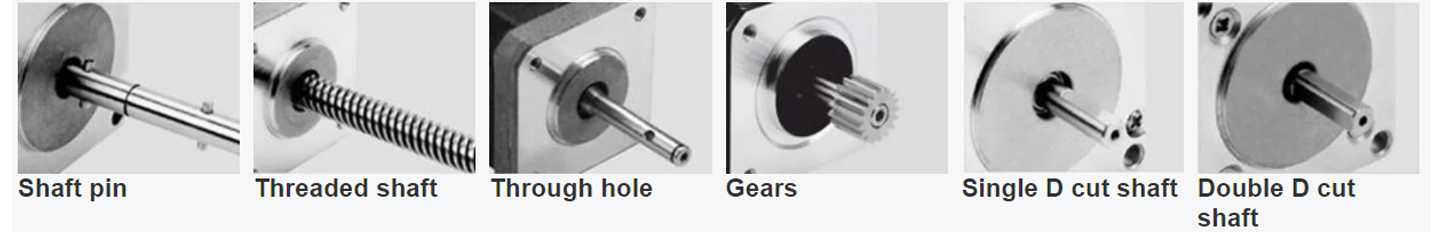

9.Different shaft type:

10.Advantages of Hybrid Stepper Motor

As the stepper motor are digitally controlled using an input pulse, they are suitable for use with computer controlled systems.

They are used in numeric control of machine tools.

Used in tape drives, floppy disc drives, printers and electric watches.

The stepper motor also use in X-Y plotter and robotics.

It has wide application in textile industries and integrated circuit fabrications.

The other applications of the Stepper Motor are in spacecrafts launched for scientific explorations of the planets etc.

These motors also find a variety of commercial, medical and military applications and also used in the production of science fiction movies.

Stepper motors of microwatts are used in the wrist watches.

In the machine tool, the stepper motors with ratings of several tens of kilowatts is used.