Shanghai Banghuai Heavy Industry Machinery Co., Ltd. |

|

MTM130 Limestone Grinding Mill

MTM Medium-speed grinding mill is a world leading tool for powder grinding. it absorbs world first-class industrial powder milling technology and organizes the technical experts and related engineers for elaborate design, test and improvement.

[Application areas]: mining, construction, chemical industry, stone

[Adapted materials]: Quartz, feldspar, calcite, limestone, talc,

ceramics, marble, granite, dolomite, bauxite, iron ore, barite,

bentonite, coal gangue, coal, etc.

2, Technical Parameters

| Spec. | Roller number | RollerSize (MM) | MaxFeedsize (MM) | Finishedsize (MM) | Overall size LxWxH(mm) | Electricpower (KW) | Electric power (KW) | WhenTheyield (T) |

| YGM7815 | 3 | 260*150 | 15-20 | 0.613-0.033 | 4300*3500*5100 | 18.5 | 15 | 0.8-2 |

| YGM8314 | 3 | 270*140 | 15-20 | 0.613-0.033 | 5300*4100*5200 | 22 | 22 | 1-3 |

| YGM9517 | 4 | 310*170 | 15-25 | 0.613-0.033 | 7100*5900*7900 | 37 | 37 | 2.1-5.6 |

| YGM4121 | 5 | 410*210 | 15-25 | 0.613-0.033 | 7850*8000*9700 | 75 | 75 | 2.8-10.5 |

| MTM160 | 6 | 440*270 | 20-35 | 0.613-0.033 | 12550*5700*8350 | 132 | 132 | 5-20 |

| MTM175 | 5 | 520*280 | 25-40 | 0.6-0.045 | 12575*9555*9916 | 160 | 200 | 13-25 |

3, Product advantages

1. High economic efficiency.

2. Three-dimensional structure, small footprint,

strong complete set.

3. More crushing pressure.

4. Better stability.

5. High level of environmental protection.

6. The operation is more convenient, the equipment is

simple to operate, and one person can easily operate it.

7. High precision of finished products.

8. Grind more fully.

9. More energy efficient.

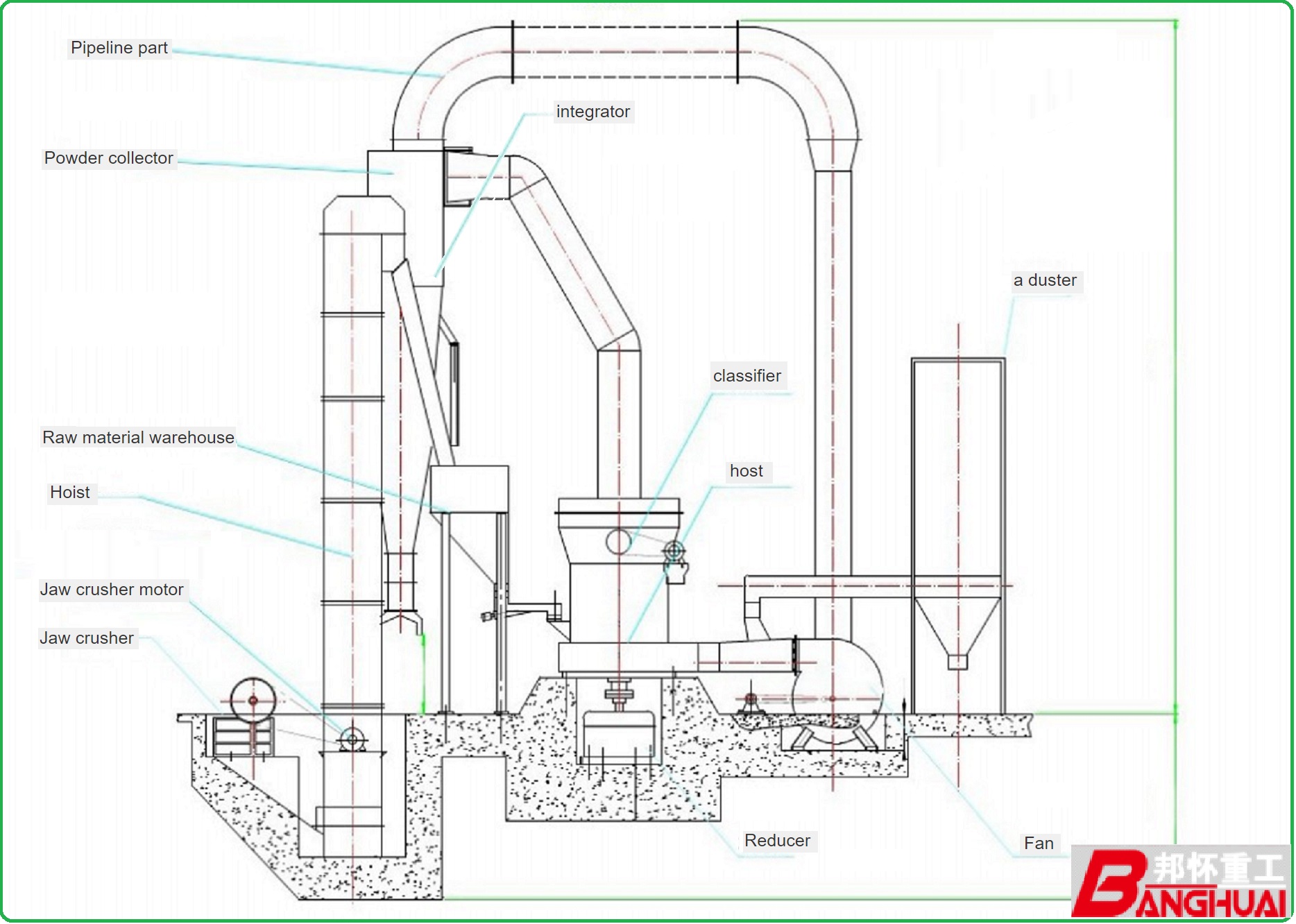

4, Working Principle

After jaw crushers break large bulky materials to smaller ones, elevators work to send materials to the hopper. Then, by electromagnetic vibrating feeders, broken materials are evenly and quantitatively sent to the grinding chamber of MTM Medium-speed Grinding Mill. After grinding, materials are blown away by airflow to the powder concentrator for classifying.

Under the action of the impeller of powder selector, materials which fail to meet fineness would be sent back to grinding chamber to get another grinding while qualified powders would be collected by cyclone powder collector and discharged from the bottom as finished products. And, after that, the airflow would go into the fan along with the air return duct at the top of cyclone power collector.

This system adopts a closed circuit and runs under positive and negative pressure. Because materials have a certain content of moisture, heat generated during grinding may lead air evaporation or swell in the grinding chamber so that the amount of airflow increases sharply. Besides, if the feed port and joints of pipelines are not sealed well, external air may intrude the grinding mill and lead imbalance of airflow.

5, Factory manufacturing and transport

Tag:

High pressure pulverizer ore, stone and stone pulverizer industrial pulverizer equipment