Shenzhen Jaguar Automation Equipment Co.,Ltd. |

|

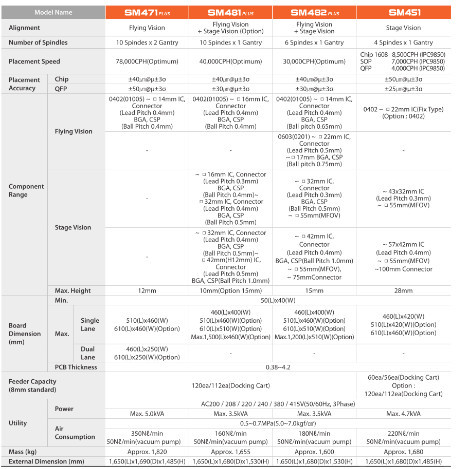

Samsung SMD pick and place machine /chip mounter favorable price

As a high performance chip shooter that applies two gantries equipped with 10 spindles per head as well as new flying vision, the SM471 realizes a chip mounting speed of 75,000 CPH, the highest in the world among chip shooters of the same class. In addition, it is applicable to 0402 chips to the largest 14mm ICs by default and increases actual productivity and placement quality by applying an electrically driven high speed and high precision feeder. Moreover, it is designed for mixed use with the SM pneumatically driven feeder to maximize the customers’ operational convenience.

75,000 CPH(Optimum)

2 Gantry x 10 Spindle/Head

Applicable Parts : 0402 ~ 14mm(H 12mm)

Applicable PCB : Max. 510(L) x 460(W)(Standard)

Max. 610(L) x 460(W)(Option)

Electrically Driven High Speed and High Precision Feeder

- Allows mixed use with an SM pneumatically driven feeder

SMART Feeder

- The world’s first feeder equipped

Samsung flexible mounter SM482

Advanced Flexible Mounter

As a general component placer whose applicability to odd-shaped

parts is reinforced based on the platform of the SM471, equipped

with a head with one gantry and 6 spindles, the SM482 is applicable

up to 55mm IC parts. It supports a polygon recognition algorithm to

provide an optimum solution for the application to odd-shaped

parts.

In addition, it has improved actual productivity and placement

quality by applying high speed and high precision electrically

driven feeders. Furthermore, since it is designed to be compatible

with SM series pneumatic feeders, it maximizes the customer’s

operational convenience.

28,000 CPH(Optimum) 1 Gantry x 6 Spindles/Head

Applicable part: 00603 ~ 42mm(H 15mm), 0402(Option)

~L75mm Connector

Applicable PCB: 460(L) x 400(W)(Standard)

Max. 740(L) x 460(W)(Option)

High speed, high precision and electrically driven feeder

- Automatic pick-up position alignment function

- Compatible with SM pneumatic feeders

New vacuum system and optimized pickup/placement motion SMART

Feeder

- World’s first Auto Splicing and Auto Loading

Advanced High Speed Flexible Mounter SM481

As a general component placer whose vision system is reinforced

based on the platform of the SM471 high speed chip shooter and

whose chip placement speed is the highest among the same class

component placers, the SM481 realized a chip placement speed of

39,000 CPH, the highest among the same class component placers, by

applying a head with one gantry and ten spindles as well as new

flying vision and by maximizing the pickup and placement motion.

In addition, it is applicable up to 0402 chips and 42mm ICs. It has

improved actual productivity and placement quality by applying high

speed and high precision electrically driven feeders. Furthermore,

since it is designed to be compatible with SM series pneumatic

feeders, it maximizes the customer’s operational convenience.

39,000 CPH(Optimum)

1 Gantry x 10 Spindles/Head

Applicable part: 0402 ~ 42mm(H 15mm)

Applicable PCB: 460(L) x 400(W)(Standard)

Max. 740(L) x 460(W)(Option)

High speed, high precision and electrically driven feeder

- Automatic pick-up position alignment function

- Compatible with SM pneumatic feeders

New vacuum system and optimized pickup/placement motion SMART

Feeder

- World’s first Auto Splicing and Auto Loading

Our Services

1, our service tenet: fast, thoughtful and thorough

2, service goals: service quality to win the user satisfaction

3. the service efficiency: the warranty period or the warranty as

equipment

failure, the supplier in the receipt of the notification, the

maintenance

personnel in one hour to respone.

4, service principle: product warranty period of 12 months, in the

guarantee

period the supplier will free maintenance and replacement of

quality caused by

he damaged parts.