Wuxi Yushun Metallurgical Technology Co., Ltd. |

|

Verified Suppliers

|

|

High Speed Diameter Φ5.5-Φ20mm Wire Rod Rolling Mill Production Line

Steel type: high quality carbon steel, low alloy steel, spring steel, alloy steel, etc.

Raw material is generally 150×150×12000mm continuous casting billet, the billet weight is 2 tons.

Maximum rolling speed 95m/s, single line production capacity of 600,000 ~ 800,000 tons/year.

Main equipment of high speed wire rod coil production line:

| 1. | 610-350 horizontal and vertical short stress path rolling mill |

| 2. | 550-350 2-hi roll horizontal and vertical closed rolling mill |

| 3. | Crops (chopping)shear |

| 4. | Water cooling equipment |

| 5. | 285 cantilevel type pre-finishing mill group |

| 6. | 10 rack 45°no-twist high speed and heavy load finishing mill group |

| 7. | Pinch roll |

| 8. | Laying head |

| 9. | Air cooling control cooling line |

| 10. | Coil collecting station |

| 11. | P/F cooling line |

| 12. | Full- automatic wire rod packer |

Main equipment of high-speed wire rod production line:

610-350 Horizontal and vertical short stress line mill, or 550-350 two-high horizontal and vertical closed mill, Cutting head (broken) flying shears, water cooling equipment, 285 cantilever pre-finishing mill group, 10 stand 45° twistless high speed and heavy load finishing mill group, pinch roll, spinning machine and loose coil air cooling control cooling line, coil collecting station, P/F cooling line, automatic wire baler, etc.

| Condition: | New |

| Type: | Steel rolling mill |

| Warranty of core components: | 1 Year |

| Core components: | Bearing, Gearbox, Motor, Gear |

| Voltage: | Customized |

| Power: | Customized |

| Dimension(L*W*H) | Customized |

| Specification: | 750,850,950,1150 |

| Certification: | ISO 9001 |

| Output: | Negotiated |

| After-sales-Service Provided: | Video technical support, online support |

| Applicable industries: | Manufacturing plant, construction works |

| Raw material: | Steel product |

| Usage: | Steel construction |

| Item: | Finishing |

| Color: | Customized |

| Finished product: | Steel |

Features:

| 1. | High dimensional accuracy, small ellipticity |

| 2. | Using distributed wind cooling, its composition is uniform, good mechanical properties |

| 3. | Because of negative tolerance rolling, it saves metal, and the high speed wire is longer than the normal wire for the same weight |

| 4. | Each piece has only one head and tail |

| 5. | The high speed wire is 20~40 yuan /t more expensive than the general wire |

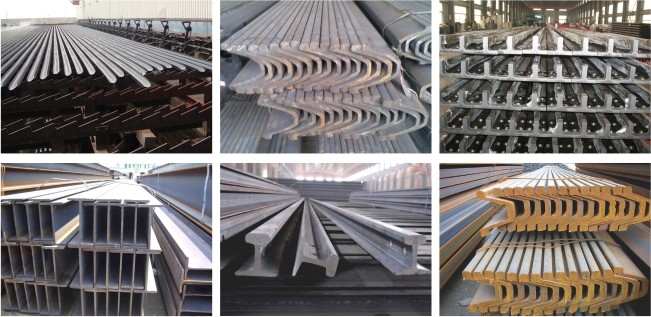

Our company can design and manufacture section steel rolling equipment including short-stress path, universal rolling mill. Specification: 750,850,950,1150. Our company can contract the turn-key project for this kind of project, the investment of which is small but the performance is good. |

Packaging Details: Wooden case packing or nude packing

Port: Tianjin

Lead Time:

| Quantity(Sets) | 1-1 | >1 |

| Est.Time(Days) | 30 | To be negotiated |

Recommed Products

Rolling mill is a mill or factory where ingots of heated metal are passed between rollers to produce

sheets or bars of a required cross section and form.

We supply the whole production lines, from induction furnace, CCM to rolling mills, cooling beds

and packing. Our hot rolling mill can produce 8-32mm deformed rebar, round bar and also wire

rod.

Technology Parameter

| Production capacity: | 50,000MT-800,000MT/year |

| Type of steel: | Quality carbon steel, low alloy steel, etc. |

| Material: | Billet size from 80mm*80mm to 150mm*150mm |

| Final products: | Φ5.5-Φ12mm wire rod, Φ8-Φ40mm rebar |