Wuxi Yushun Metallurgical Technology Co., Ltd. |

|

Verified Suppliers

|

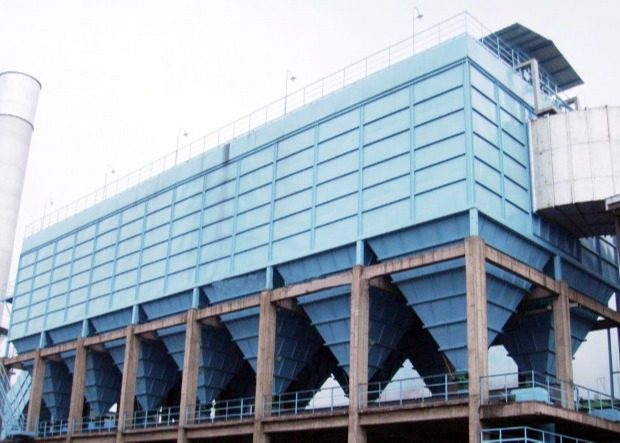

Dust Collector/Welding Dust Removal Equipment/Fume Extractor for

Steel Production Line

Air box pulse bag filter, our company makes it in the advanced level of high efficiency. It combines the advantage of chamber blow and injection pulse soot cleaning of all kinds of bag filter, and overcomes the disadvantage of the chamber blow soot cleaning insufficient strength, and the injection pulse ash removal and filtering simultaneously, thus expands the application range of bag filter. Due to the structure has the characteristics of this type of filter, so it improves the efficiency of dust, prolong the service life of filter bag.

The working principle of bag type dust collector is as follows: rely on woven or felt woven (pressure) filter cloth as filter material,

when dust gas passes through the filter bag, dust is blocked on the surface of the filter bag, dry air is discharged through the gap between the filter bag fibers, so as to achieve the purpose of separation of dust gas and dust.Its working mechanism is the dust through the filter cloth screen, inertia, adhesion, diffusion and static electricity and other effects and capture.

| Model | DMC-24 | DMC-36 | DMC-48 | DMC-64 | DMC-80 | DMC-96 | DMC-120 |

| Total filtration area(m3) | 18 | 27 | 36 | 48 | 60 | 72 | 90 |

| Filter wind speed(m/min) | 1.04-1.67 | 1.15-1.62 | 1.21-1.71 | 1.25-1.67 | 1.27-1.62 | 1.28-1.7 | |

| Processing air volume(m3/h) | 1500 | 1500-2400 | 2500-3500 | 3500-5000 | 4500-6000 | 5500-7000 | 6500-8500 |

| Number of filter bags(bars) | 24 | 36 | 48 | 64 | 80 | 96 | 120 |

| Air consumption(m/min) | 0.024 | 0.036 | 0.048 | 0.064 | 0.08 | 0.096 | 0.12 |

| Pulse valve(set) | 4 | 6 | 6 | 8 | 10 | 12 | 12 |

| Motor model(kw) | 2.2 | 3 | 3 | 5.5 | 5.5 | 7.5 | 15 |

| Equipment weight(kg) | 300 | 500 | 850 | 1220 | 1450 | 2150 | 2550 |

| Inlet concentration(mg/Nm3) | 200 | ||||||

| Injection pressure(Mpa) | 0.5-0.7 | ||||||

| Withstand negative pressure(pa) | 5000 | ||||||

| Equipment resistance(pa) | ≦1200 | ||||||

Features:

1. 99.9% high dust removal efficiency, especially for micro dust.

2. PPC dust collector uses offline ash removal method, when a chamber is removing dust, the filter air flow will be cut off to avoid producing the secondary dust float in the sky, it improves the effect and extended the service life of the filter bag.

3. It can capture different nature dust with the strong adaptability.

4. PPC Dust collector machine adopts air box structure to reduce the part resistance, and make it easier to install the filter bag.

5.Simple structure, stable operation, convenient maintenance operation

1.What annual output do you require?

2.What is the main size range of rebar?

3.How long is the billet?

4.What is the fuel for the furnace?

5.How long does the machine work continuously?

And anything else you think necessary.

Selling Units: Single item

Single package size: 150*100*170cm

Single gross weight: 100,000kg

Package Type: Safety Seaworthy Package

Lead Time:

| Quantity (Tons) | 1-100 | >100 |

| Est. Time(Days) | 60 | To be negotiated |