Hebei Guixiang International Trade Co., Ltd. |

|

Verified Suppliers

|

|

This is the simplest form of weave where the wires are simply crimped and placed into position. The crimp on each wire provides a firm hold of the intersecting wire, maintaining the rigid structure of the mesh. In the double crimp weave, both warp wires and weft wires are crimped.

This is characterized by wires that are precisely crimped prior to weaving. This results in additional stability and rigidity, which allows for larger openings in relation to wire diameter. Best suited for applications where load impact is to be expected.

The distinguishing feature of this type is its straight sections of wire followed by a crimp, which allows for more accurate control over the mesh's structure. This type of crimp is typically used when the opening size exceeds half an inch.

Here, the wires are crimped before they are woven, so one side remains flat. This type is typically used where a strong structure is needed but smooth top surface is preferred – for example, for vibrating screens in the mining industry.

In this type of weave, both the warp and weft wires are crimped before they are woven together. The final weave has stable structure and uniform squares, making it particularly suitable for heavy-duty applications.

Choosing the right weave type depends on where and how the crimped wire mesh will be used. By understanding the unique benefits of each, one can make an informed decision tailored to specific project requirements.

1. Wire Drawing: The process begins with wire drawing, where wire rods of larger diameter are drawn into wire filaments of smaller diameters.

2. Weaving or Welding: The wires are then woven or welded into a grid structure to form the basic shape of the mesh. At this stage, the wire mesh is flat and has not yet been crimped.

3. Crimping: Next, the wires undergo a crimping process. This involves passing the flat wire mesh through a specialized crimping machine. The machine presses each wire into a series of peaks and valleys, resulting in a wavy appearance – this is the 'crimp'.

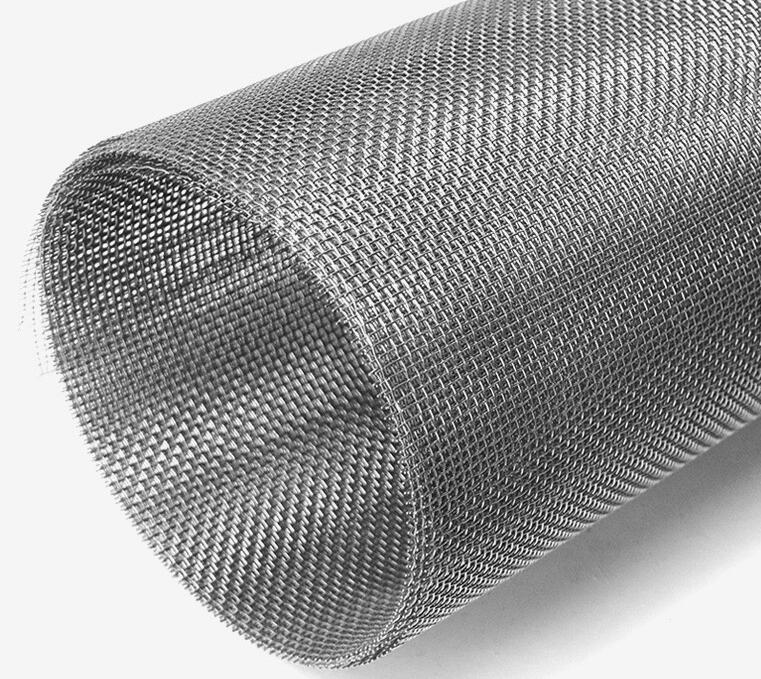

4. Cutting or Rolling: After crimping, the mesh is either cut into sheets or rolled up in desired lengths.

The crimping process gives the wire mesh additional rigidity and strength, enabling it to withstand greater loads compared to a flat wire mesh.

Stainless steel as a material for crimped wire mesh offers numerous advantages:

It is due to these attributes stainless steel crimped wire mesh is often preferred in industrial, architectural, and household applications.