Dongguan Quality Control Technology Co., Ltd. |

|

Fully Automatic Micro Vickers Hardness Tester With 2 Indenters And 3 Objectives

Technical Data Download:iqualitrol Micro Hardness Tester iVick-459ST

Product Features:

New generation automatic Micro Vickers hardness tester iVick-459ST adopts the integrated design with panel computer. Panel computer equips with Windows 7 operating system, all the testing parameters can be selected and preset by touch screen computer, makes operation quickly and conveniently and displays clearly and intuitively.

iVick-459ST can show the indentation image directly on the touch screen and automatically get the Vickers hardness value by CCD image acquisition system.

iVick-459ST takes over the old method of measuring the diagonal length by eyepiece, avoids the stimulation and visual fatigue of the light source of the eyepiece, and protects the eyesight of the operator.

With two indenters and three objectives, automatic recognition and turret between the objective and the indenter, support hardness scales conversion.

With USB, VGA and LAN interfaces, the hardness measurement can be printed out by USB interface, and can automatically save the measuring data, generate the hardness-depth curve and save as WORD or EXCEL document.

With motorized X-Y test table, automatic focusing and automatic measuring, it realizes the fully automation of Micro Vickers hardness testing.

Application range:

Suitable for ferrous metal, non-ferrous metals, IC thin sections, coatings, ply-metals; glass, ceramics, agate, precious stones, thin plastic sections etc.; hardness testing such as that on the depth and the trapezium of the carbonized layers and quench hardened layers.

Technical Specification:

| Model | iVick-459ST | |

| Test Force | gf | 10gf, 25gf, 50gf, 100gf, 200gf, 300gf, 500gf, 1000gf |

| N | 0.098N, 0.246N, 0.49N, 0.98N, 1.96N, 2.94N, 4.90N, 9.80N | |

| Test Range | 1HV~2967HV | |

| Test Mode | HV/HK | |

| Loading Method | Automatic (Loading/Dwell/Unloading) | |

| Turret | Automatic Turret (Two Indenters, Three Objectives) | |

| Computer | CPU: Intel I3, Memory: 2G, SSD: 32G | |

| CCD Pixel | 1.30 Million | |

| Conversion Scale | HV, HK, HRA, HRB, HRC, HRD, HRE, HRF, HRG, HRK, HR15N, HR30N, HR45N, HR15T, HR30T, HR45T, HS, HBW | |

| Hardness Reading | Indentation Displaying and Automatic Measuring on Touch Screen | |

| Data Output | WORD or EXCEL Report with Curve Chart | |

| Objective | 10X (Observe), 20X (Measure), 40X (Measure) | |

| Total Magnification | 100X, 200X, 400X | |

| Resolution | 0.03μm, 0.015μm | |

| Dwell Time | 0~60s | |

| Light Source | Halogen Lamp | |

| Motorized X-Y Test Table | Size: 110×110mm; Travel: 50×50mm; Resolution: 0.002mm | |

| Max. Height of Specimen | 185mm | |

| Throat | 130mm | |

| Power Supply | AC220V/50Hz/1Ph | |

| Execute Standard | ISO 6507, ASTM E384, JIS Z2244, GB/T 4340.2 | |

| Dimension | 560×335×675mm, Packing Dimension: 650×380×960mm | |

| Weight | Net Weight: 52kg, Gross Weight: 67kg | |

Packing List:

| Instrument Main Body | 1 set | Diamond Micro Vickers Indenter | 1 pc |

| Diamond Knoop Indenter | 1 pc | 10x, 20x, 40x Objective | each 1 pc |

| Weights | 7 pcs | Motorized Cross Test Table | 1 pc |

| Flat Clamping Test Table | 1 pc | Filament Clamping Test Table | 1 pc |

| Thin Specimen Test Table | 1 pc | Level | 1 pc |

| Horizontal Regulating Screw | 4 pcs | Screw Driver | 1 pc |

| Inner Hexagon Spanner | 1 pc | Color Filter | 1 pc |

| Plastic Absorbing Plate | 1 pc | Fuse 1A | 2 pcs |

| Power Cable | 1 pc | Halogen Lamp 12V/15~20W | 1 pc |

| Hardness Block 400~500 HV0.2 | 1 pc | Hardness Block 700~800 HV1 | 1 pc |

| Hardness Block 700~800 HK1 | 1 pc | Anti-dust Cover | 1 pc |

| Usage Instruction Manual | 1 copy |

The Vickers hardness test method consists of indenting the test material with a diamond indenter, in the form of a right pyramid with a square base and an angle of 136 degrees between opposite faces subjected to a load of 1 to 100 kgf. The full load is normally applied for 10 to 15 seconds.

The two diagonals of the indentation left in the surface of the material after removal of the load are measured using a microscope and their average calculated. The area of the sloping surface of the indentation is calculated. The Vickers hardness is the quotient obtained by dividing the kgf load by the square mm area of indentation.

When the mean diagonal of the indentation has been determined the Vickers hardness may be calculated from the formula, but is more convenient to use conversion tables.

The Vickers hardness should be reported like 800 HV/10, which means a Vickers hardness of 800, was obtained using a 10kgf force. Several different loading settings give practically identical hardness numbers on uniform material, which is much better than the arbitrary changing of scale with the other hardness testing methods.

The advantages of the Vickers hardness test are that extremely accurate readings can be taken, and just one type of indenter is used for all types of metals and surface treatments. Although thoroughly adaptable and very precise for testing the softest and hardest of materials, under varying loads, the Vickers machine is a floor standing unit that is more expensive than the Brinell or Rockwell machines.

The Knoop hardness test method is mostly used for small parts, thin sections, or case depth work. Knoop indentation is very small, the main application like below:

testing very thin materials like foils or measuring the surface of

a part,

small parts or small areas,

measuring individual microstructures,

measuring the depth of case hardening by sectioning a part and

making a series of indentations to describe a profile of the change

in hardness.

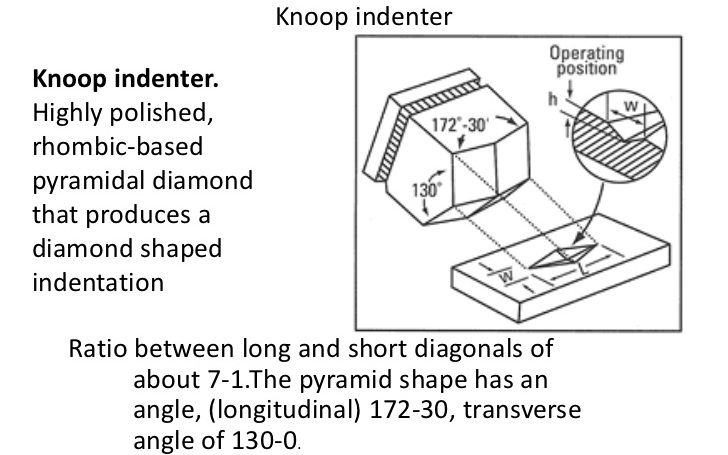

The Knoop indenter is a pyramid shaped diamond is more elongated or rectangular in shape. The Knoop method is commonly used when indentations are closely spaced or very near the edge of the sample.

The width of the Knoop indentation can provide more resolution for measurement and the indentation is also less deep. Consequently, it can be used on very thin materials.

EXPORT STANDARD SEAWORTHY PACKING: