Dongguan Quality Control Technology Co., Ltd. |

|

0.5HR Resolution Manual Loading Rockwell Hardness Testing Machine Max Vertical Space 400mm

Applications:

Rockwell hardness measurement of ferrous metals, non-ferrous metals

and non-metallic materials.

Wide range of applications, suitable for rockwell hardness testing

of hardening, quenching and other heat-treated material.

XRock-150M is suitable to determine the Rockwell hardness of ferrous, non-ferrous metals and non-metal materials. It can be widely applied in the Rockwell hardness testing for heat treatment materials, such as quenching, hardening and tempering, etc.

Mainly Functions:

● Lever Loading, manual operation, durable and reliable.

● No friction spindle, high precision test force.

● Precision hydraulic buffers, steady load.

● Dial display the hardness value, HRA, HRB, HRC, and can choose

other Rockwell Scale.

● Accuracy according to GB / T230.2, ISO 6508-2 and American ASTM

E18 standard.

Technical Specifications:

| Product name | Manual Rockwell Hardness Tester |

| Model | XRock-150M |

| Measuring range | 20-88HRA, 20-100HRB,20-70HRC |

| Dial pointer range | HRA, HRC (black): 0-100; HRB (red): 30-130 |

| Preliminary test force | 10kgf (98.07N) |

| Rockwell test force | 60Kgf(558.4N), 100Kgf(980.7N), 150Kgf(1471N) |

| Hardness indication | Dial Reading |

| Resolution | 0.5HR |

| Loading control | manual |

| Max height of specimen | 400mm |

| Instrument throat | 220mm |

| Dimension | 650 x 210 x 1020mm |

| Packing dimension | 680 x 420 x 1270mm |

| Gross/ Net weight | 150Kg/120Kg |

| Execution standard | GB/T230.2, JIS Z2245, EN-ISO 6508, ASTME-18 |

Standard Accessories:

| Instrument main body | Ø1.588mm ball indenterl | Weight A |

| Ø58mm V-shape anvil | Ø1.588mm Steel ball | Weight B |

| Hardness block | Cone diamond indenter | Weight C |

| Anti-dust cover | Ø150mm Flat anvil | Accessory box |

| Warranty card | Qualified certificate | Instrument manual |

The Rockwell test consists of measuring the additional depth to which a carbide ball or diamond penetrator is forced by a heavy (major) load beyond the depth of a previously applied light (minor) load (SET point).

The minor load is applied first and a SET position is established on the dial gauge or displacement sensor of the Rockwell tester. Then the major load is applied. Without moving the piece being tested, the major load is removed and, with the minor load still applied, the Rockwell hardness number is automatically indicated on the dial gauge or digital display.

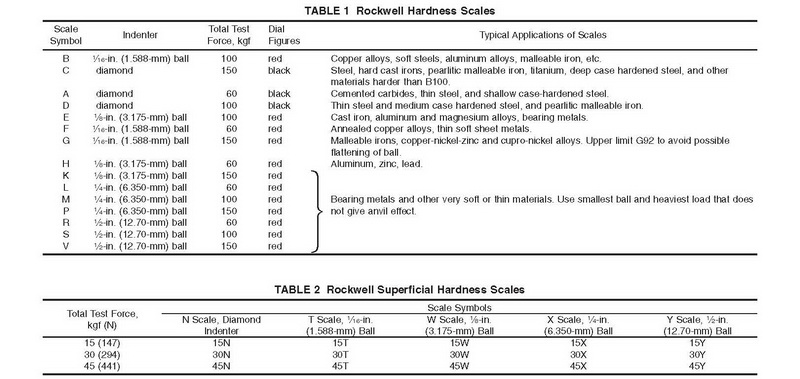

The diamond penetrator is used for testing materials such as hardened steels and cemented carbides. The carbide ball penetrators, available with 1/16 inch, 1/8 inch, 1/4 inch, and 1/2 inch diameter, are used when testing materials such as steel-copper alloys, aluminum and plastics to name a few.

Rockwell testing falls into two categories: Regular Rockwell testing (e.g., C and B scales) and Rockwell superficial testing (e.g., 30 N and 30 T scales).

High Rockwell hardness numbers represent hard materials and low numbers soft materials.