Guangzhou Andea Electronics Technology Co., Ltd. |

|

Verified Suppliers

|

|

Automobile Factory Process Automation Management UHF RFID Reader Modbus Communication Reading Distance 0-3m

An automobile factory process automation management system can benefit greatly from the implementation of UHF RFID readers with Modbus communication capabilities. These readers can be strategically placed throughout the production line to scan tags on various parts, components, and assemblies. The data collected can then be communicated in real-time to a central control system via Modbus protocol.

With a reading distance of up to 3 meters, the UHF RFID readers can quickly scan tags attached to moving vehicles or parts, allowing for seamless identification and tracking. This streamlines the production process, reduces errors and misplacements, and increases overall efficiency.

The Modbus communication protocol is widely used in industrial automation systems and allows for easy integration with existing control systems. By using a common communication protocol, the UHF RFID readers can seamlessly communicate with other components of the factory automation system, such as programmable logic controllers (PLCs) and human-machine interfaces (HMIs).

| Specification | |

| Support Standard | ISO18000-6C,EPC C1G2 |

| Operating Frequency | 860~960MHz |

| Reading Range | 0-3m |

| Communication mode | ARU2301T:Modbus TCP ARU2301M:RS485 ARU2301R:RS232 |

| Communication rate | ARU2301T:10/100M bps ARU2301M/R:9600~115200 bit/s |

| Power Supply | ARU2301T:48V POE(46-54V),24V DC(9~30V) ARU2301M/R:24V DC(9-30V) |

| Current | <0.38A@24V DC |

| Physical parameters | |

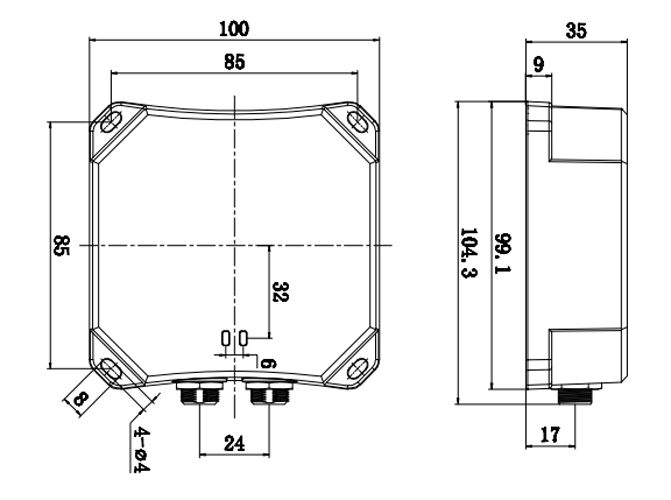

| Dimension | 100*100*35mm |

| Weight | 160g |

| Fixed type | 4*M4 screw |

| Housing Material | ABS and Metal plate |

| Color | Black |

| Indicator light | LED*2 |

| Interface | ARU2301T:M12A(4pin M) + M12D(4pin M) ARU2301M/R:M12A(4pin M) + M12A(5pin M) |

| Application environment | |

| Working Temperature | -40℃~+85℃ |

| Humidity | 5%~95%RH |

| Waterproof/dustproof | IP67 |

Application:

Factory Automation

This product has always been a key player in the field of discrete manufacturing with its strong portfolio comprising sensors, connection and fieldbus technologies, RFID and control solutions. Our comprehensive solutions help our customers to improve efficiency, increase availability and minimize errors.

Engine Assembly Line

The reader can interface with various PLCs such as Siemens,Schneider and Mitsubishi through the industrial bus controller. By reading the RFID tag mounted on the tray,passing the information to the PLC, Through the information of installation to guide the assembly robot or the assembler to auto select the appropriate part,the engine assembly efficiency can be greatly improved.

Power Battery Assembly

Install the reader at the RFID collection point, and the on-line station collection point reads the RFID tag in the material box to obtain the information of slots in the material box (each slot is equipped with a cell with different voltage), The voltage value/grade of the test cell is written into the material box RFID tag at the test station of the voltage cell. When the cell is classified, read the RFID tag information of the material box and connect the robot in real time to automaticaly put the cell into the corresponding cell transport track. After the robot takes down the cell with different gear from the transport track and puts them into the same material box it will write the cell gear information into the RFID tag of the material box. Through the operation of each station on the RFID tag, a series of processes such as cell division, transportation, encapsulation, and assembly are completed in the process of cell assembly.

Dimension Drawing(mm):

FAQ

1. What’s your Payment?

PayPal or T/T (Bank transfer) or Western Union and Ali trade Assurance are accepted.

2. What's your MOQ?

Big Order or Sample Order is accepted by our company.

We understanding new customers may take sample testing to know our quality and service.

3. What is the warranty?

3 years warranty for core device from the date of delivery,A lifetime technical support.

We will return full money to customer if we did not shipping right items as contract.

4. What’s your delivery time?

Around 2~10 working days according to exact order quantity and stock situation.

5. Why choose us?

With us make Win-Win Business Situation!!!

24 *7 hours after sales service

We accept "PayPal", credit card to convenient customer make payment.

Quality Assurance Contract

Full refund in case of bad quality

Online supports if any technique issue.

Both Small Order and Big Order are accepted.

Accept OEM/ODM order.