Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Manual Argon Gas Filling Machine for Making Insulating Glass Processing

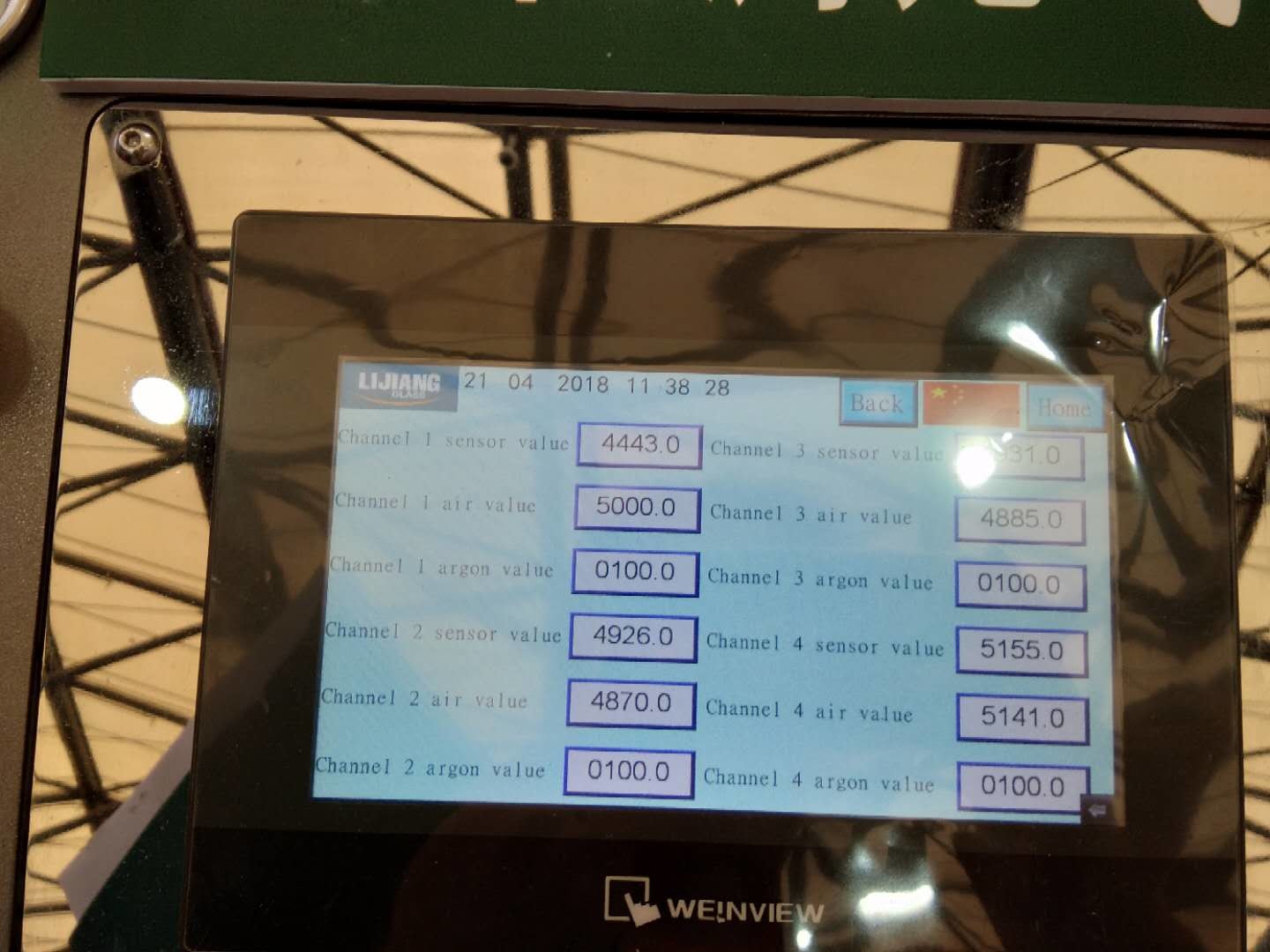

Smart insulating glass gas filling machine LJCJ02 is a special equipment for filling argon into insulating glass. The device by microcomputer and imported from the sensor to form a closed loop control system, high degree of intelligent equipment, precise control, pneumatic concentration adjustable, charging efficiency is high, the operation is simple. It is essential to further improve the performance of the hollow glass equipment.

1. Specifications and technical date of argon gas filling machine :

| Item | Value |

| Power supply | AC220 V 50Hz |

| 0.5kw | |

| Contour dimension | 600X400X1210mm |

| Machine net weight | 40kg |

2. The conditions of use

1.The argon gas source: pressure 0.2Mpa.

The air compressor machine source: pressure 0.4Mpa.

The use of the environment: 0~40 ℃, no condensation, operation panel and control box can not have water intrusion.

3. Main structure of production

Gas filling machine comprises tree parts. There are filling gas, controlling and detection. The filling gas part mainly comprises outlet circuit, return circuit and control valve. The controller part mainly comprises touch screen, start group selection switch, controlling button, controller and buzzer alarm. Detection part mainly comprises sensor.

4. Main feature of argon gas filling machine

• It is used for filling Argon into insulating glass

• High effectively, allowed for four pieces of IGU

• When the gas is full, it will alarm and stop automatically

• Can set and display the data of gas value

5. Installation and adjustment

5.1 The equipment placed smoothly, pay attention to prevent the fall and damage controller and control system.

5.2 Connect the power socket, the total air interface, the outlet pipe and the return pipe.

6.Before inflation to adjust the technical parameters

6.1 when adjust the argon gas flow, through the control valve on the panel.

6.2 Inflation pressure setting:In order to avoid the insulated glass damage because of the high inflation pressure.You need to make the working pressure is 0.2Mpa, adjust the argon gas reducing valve in the control panel into 0.1-0.2mpa, Inside the machines box, make the air resource of air compressed machines into 0.4mpa.

According to the size of the insulating glass and the inflation rate to set the upper and lower limits of pressure, when the double glass bigger than 1.5 m X 1.5 m, the air resource of air compressor properly adjusted bigger value.

Manual Argon Gas Filling Machine For Insulating glass processing

Main feature

• It is used for filling Argon into insulating glass

• High effectively, allowed for four pieces of IGU

• When the gas is full, it will alarm and stop automatically

Technical data

| Power supply | 220V 50Hz |

| Total power | 0.1kw |

| Dimension | 620*439*700mm |

Description of Two pump Sealant-spreading Machine

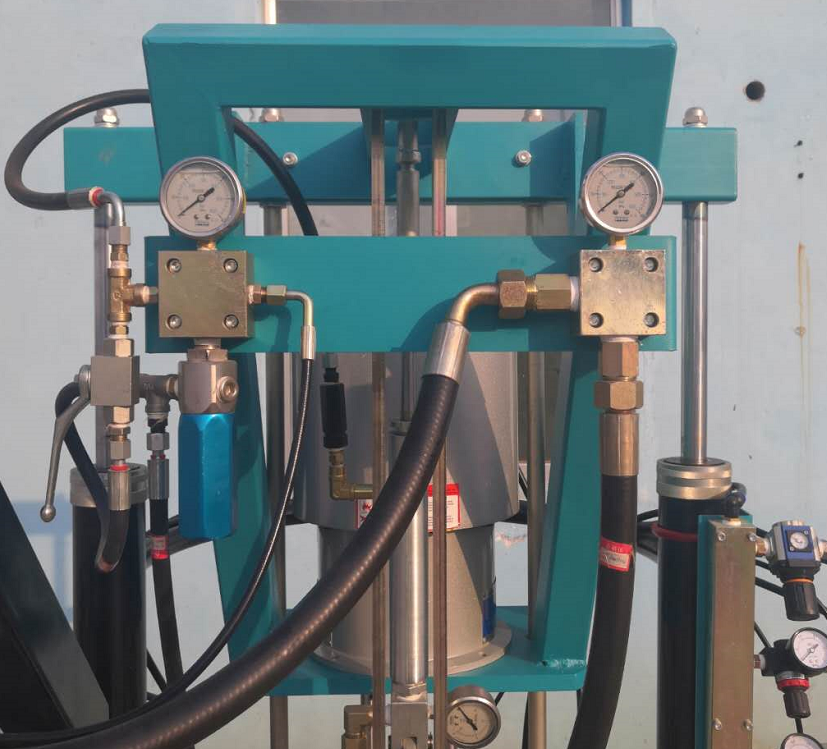

Two component gluing machine is used to apply the second layer of

sealant to the insulating glass.

It is special equipment used for spreading the two-component polysulphide glue and/or two-component silicone structure glue for the aluminum type insulating glass or curtainwall glass.

Sealant-spreading Machine is featured by uniform mixture and continuous stability of extruded glue, good spreading effect and high production efficiency.

Advantage of sealant spreading machine

• Imported motor system to improve equipment efficiency

• Imported sealant gun,stainless steel mixer

• High pressure protect device

• Anti-back flow control structure

• Mixed rate detector can control the rate of two kinds of glue

Main technical parameter of Silicone sealant spreading Equipment

| Working air pressure | 0.3-0.6MPa |

| Sealant spreading pressure | 15-20MPa |

| Sealant volume | 4L/min |

| Diameter of A/B sealant | 570mm/280mm |

| Sealant spreading air pressure ratio | 50:1 |

| Mixed rate | 6:1-14:1 |

| Air supply | Flow 0.8m3/min |

| Air pressure | ≥0.8MPa |

| Overall dimension | 1100*950*1630mm |

| Weight | 490kg |

| Capacity of the glue drum | 200-300 ml/200 kg |

The feature of sealant spreading machine

1.A and B pump adopt Korea brand HASCO.So it can ensure the

reliable working-effect.

2.Special check valve in proportioning pump to make the sealant

coming out more fluently , suitable for all kinds of sealant ,avoid

incomplete mixing .

3.Sealant extruder machine is featured by uniform mixture and

continuous stability of extruded glue, good spreading effect and

high production efficiency.

4.The rotating arm is equipped with a universal device, flexible

and portable .

5.Pneumatic control ,split type structure ,easy to operate

Rotated Sealant Spreading Table LJSK02

Main feature

• Easy operating, simple and flexible

• It is used for fixing and rotating glass when manual coating the outside of IG glass

• The middle sucker is suitable for small pieces of glass,however,extra support frame is for large pieces of glass

Technical data

| Power supply | 380V 50Hz |

| Total power | 0.37kw |

| Operating dimension | 1500*1500mm |

| Dimension | 600*550*985mm |