Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

Butyl extruder can make primary sealing of different thickness spacer bars for insulated glass units.

Product overview of butyl rubber extruder machine

Butyl rubber extruder machine is used for spreading aluminum spacer frames evenly with hot melt butyl,it is the second seal of Insulating glass.The operation of butyl rubber extruder machine is more easier than before,it uses large electrical control panel . The speed can be adjusted from 0m/min to 47m/min. Butyl extruder machine LJTB01 is a special equipment for the production of making double glazing glass.The conveyor of aluminum is controlled by frequency converter. As one of the important equipment of producing double glazing glass, the effect of butyl glue is directly related to the sealing of insulating glass. Butyl extruder machine is automatic one, easy to operate and convenient to use.

Main feature of butyl extrusion coating machine

1. The hydraulic system imported from Germany is adopted to ensure even and full glue delivery

2. The main accessories are German brands. PLC program control, stable performance

3. Touch screen operation, simple and easy operating,Stable performance

4. The rubber cylinder adopts pull-up structure, which is convenient for operation

5.Unique design structure, with automatic exhaust function, to ensure continuous glue application

6. It can save the glue consumption compared with the ordinary butyl rubber machine, and the gluing can reach 7g / m

6. Automatically adjust the glue output according to the speed change

7. Glue application speed can reach 47m / min

8. It is convenient to adjust the height of the crossbeam and solve the problem of exposed white effectively and conveniently

9. Non adhesive synchronous belt is used, and talcum powder is not needed for cleaning

10. It is convenient and practical to use movable vertical and horizontal sealant

11.Automatically adjust the width of glue head, and the integrated control of quick opening valve ensures the consistency of double-sided gluing

Tech data of High speed butyl extruder machine

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 5.5-26.5mm |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 650kg |

Machine details of Aluminum spacer butyl extruder machine

1.KINCO Touch Screen

Clear interface, Simple operation, Smart touch screen,Updated programming

2.Adopt Germany Siemens brand, stable performance.

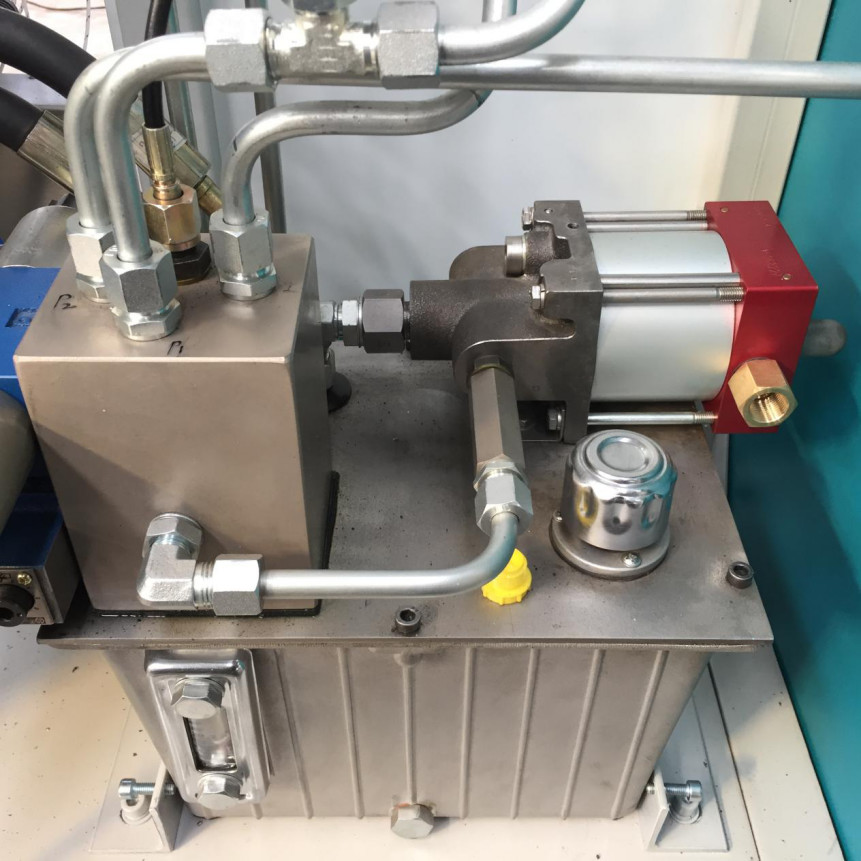

The supercharging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

3.Automatic filter function

Automatically filter debris, keep spreading evently.

4.Glue cylinder

Adopt the upright structure, easy to change butyl.

5.Germany HAVE Valve

Adopt Germany’s Harvey valve, more stable performance.

6.Alarm system

Automatically alarm system, reminding adding butyl.

7.Guiding Wheel

Using guiding wheel to help arc frames coating.

8.Germany Maximator Cylinder

The supercharging system adopts famous pneumatic and hydraulic cylinder, control the pressure of outlet oil strongly.

Optional functions of butyl coating machine:

200L glue cylinder is optional

Related Products

1.Glass washing machine

Main feature:

• Using 6 pieces of soft brushes

• Wash online and offline low-e glass, automatically recognizes Low-e film

• Washing part adopts the design of upper and lower layered structure

• Adopt variable frequency fan, energy efficient, good cleaning effect

• The air knife can automatically adjust the width of the air knife according to the thickness

• Using intelligent intermittent energy-saving working methods

• Hierarchical type washing system

• Water tank automatic temperature control, water replenishing system

• European silencer system

• 304 stainless steel materials

2.Automatic double glazing making machine Insulating Glass Manufacturing Line double glass equipment

Now LIJIANG GLASS mainly has two kinds of IG line with different two different technologies. One uses transfer wheels to transport glass, and the other is a new technology that uses air-floating technology to transport glass. This new technology is to prevent the glass from being contaminated by wheels and leaving traces, so new technology is used to improve the IG production’s high quality.

Functions :

double glazing glass

triple glazing glass

four sides step glazing glass

Automatic Insulating Glass Production Line series

| Unit | LJBZ2025 | LJBZ2025G | LJBZ2535 | LJBZ2535G | LJBZ2535DG | LJBZ2535GS | |

| Power supply | 380V50Hz | ||||||

| Total power | KW | 39.5 | 36 | 41 | 39.5 | 44 | 40 |

| Washing speed | m/min | 2~10 | |||||

| Maximum working speed | m/min | 45 | |||||

| Minimum glass size | mm | 450*280 | |||||

| Maximum glass size | mm | 2000*2500 2000x3000(Secondary pressure plate) | 2500*3200 2500*3500(Secondary pressure plate) 2500x4500(Secondary plate pressing and auxiliary sucker mechanism) | 2500*3500 | |||

| Flat glass thickness | mm | 3~15(3-30) | |||||

| Washing brushes | Pieces | 6 | |||||

| Maximum thickness of insulating glass | mm | 60 | |||||

| Total gas consumption | L/min | 1200 | 1200 | ||||

| Conveyer roll height | mm | 520 | |||||

| Dimension | L*W*H (mm) | 19500*3500*3200 | 23500*3500*3700 | 27000*3500*3700 | 23800*3200*3700 | ||

Automatic insulating glass production line LJBZ2025 is not include gas filling function,can make max glass size 2000*2500

Automatic insulating glass production line LJBZ2025G is include gas filling function.

Automatic insulating glass production line LJBZ2535 is not include gas filling function,can make max glass size 2500*3200

Automatic insulating glass production line LJBZ2535 is include gas filling function,can make max glass size 2500*3200

Automatic insulating glass production line LJBZ2535DG can filling argon gas two pieces at one time,can make max glass size 2500*3200

Main Features of IG Line:

• Adopt SIEMENS control system, keep stable performance

• PLC control system, touch screen interface

• Using servo to control system, modular function, superposition function

• Automatically adjust the depth of glue with digital display

• Applicable to produce stepped IG, triple IG and shaped IG

• Min & Max glass sizes can be optional

• Two pieces of IGU can be made and filled with argon gas in one time (Optional)

• Automatic Vertical Insulating Glass Processing Line has 7 sections:

01 transfer section;

02 washing section;

03 discharge section;

04 inspection and installation section;

05 transfer section;

06 pressing and filling section;

07 discharge section.

Washing section features:

• Using 3 pairs of soft brushes with 0.1mm soft hair, can wash low-e glass

• The air knife can automatically adjust the width of the air knife according to the thickness

• The operation box with washing speed display, can accurately display washing speed (8-10m)

• European silencer system

• New air knife uses aluminum profile (Duckbill Air Knife), the size of the air outlet is adjusted by the aluminum profile duck beak. This can reduce the number of adjusting screws, ensure that each screw is not loose, and avoid the resonance of the air knife.

• Stainless steel material

• Water tank automatic temperature control, water replenishing system

• Pre-washing (Optional)

Pressing section features:

• Pressing board with adjustable structure to guarantee long-lasting service life

• Adopts conveyor belt to transfer glass, uses servo motor to press glass

• Ultra-long (2500mm*3500mm) insulating glass can be compressed twice

• The pressing plate can be opened for easy maintenance

Filling argon gas automatically

• Automatically filling argon gas inside the pressing plate with precise gas concentration

• When filling shaped IG, inflatable front side of the rectangular size required 450mm (length), 280mm (high)

• Automatically set gas data and display data on the screen

• No need to drill holes in spacer frame

• Standard gas is Argon gas

• Fast reacting sensor for permanent control of gas filling process

Special technology of IG Line :

Making two pieces of IG units in once time

Shaped glazing glass

Low-e film glazing glass

Filling argon gas online

Air floating insulating glass line

3.Automatic aluminum spacer bending machine LJZW2020

Automatic aluminum spacer bending machine is a special equipment for making aluminum frames of insulating glass, which replaces the traditional fabrication technology. This equipment can make a variety of convex polygonal aluminum frames by one aluminum strip in one time, thus strengthening the strength of the aluminum frame, making the sealing effect of the insulating glass more better.

Main features

Tech parameters of High speed butyl extruder machine

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Glue thickness | 0.3-0.5mm |

| Glue width | 3.5mm |

| Aluminum spacer width | 5.5-26.5mm |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 650kg |