Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

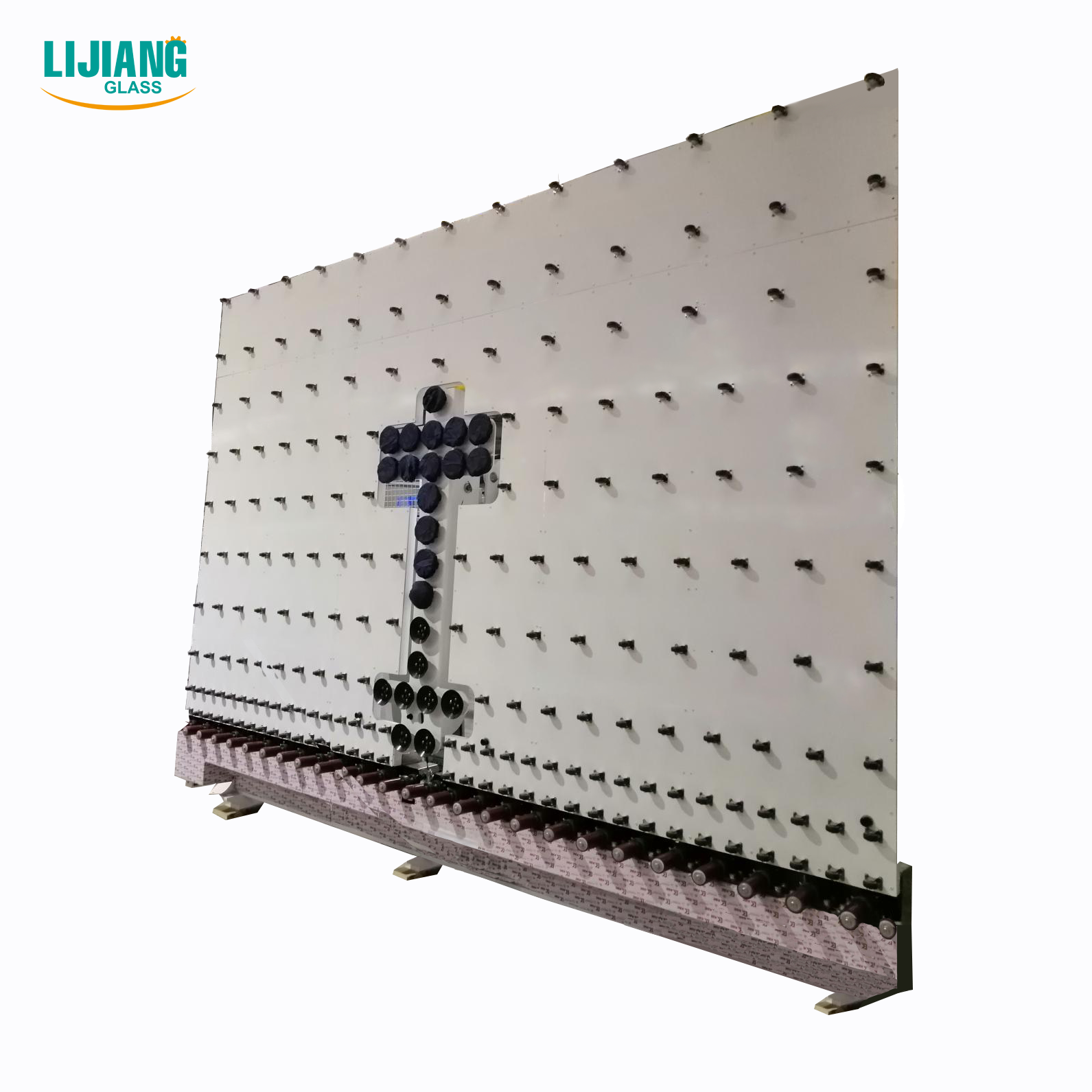

500Kg Sucker Car

Product description:

The glass suction cup car is operated for electric and hydraulic. The whole system consists of electric vacuum device, electric performance device, hydraulic performance device, electric drive system and safety protection system, which can realize the operation of clamping, lifting and carrying the glass to a specific position. It can also be assembled into various models to adapt to different systems.

| Information | Details |

| Suitable for lifting | Material properties: Gastight/ non-porous, smooth surface Example: flat glass, building glass, various kinds of processing glass and special glass |

| Weight | 500KG |

二,FREDDIE

| Name | Type:FVL-CS500-10 500KG |

| Safe Load Capacity | 500kg,

|

| Body Size | 2850mm*1200mm*1750mm |

| Suckers Description | Black rubber, abrasion resistant, |

| Power | 200Ah (24V)*4pcs |

| Charge power |

110V~ 240V, 50/60Hz |

| Machine power | 4KW |

| Weight | 500KG |

| Suitable material | Glass |

| Using way | Manual operate |

| Product Weight |

1500kg |

Noise level

| Less than 70 Db |

三,FREDDIE

| Hydraulic tilt 180° upwards and downwards with stopping at any position. | |

| Hydraulic head slew left & right 90°with stopping at any position. | |

| Hydraulic lift up and down up to 4000mm. | |

Functions |

Hydraulic extend the lifting arm to 1000mm. |

| Electric motor car, control by steering wheel | |

| Hydraulic move left & right 90° | |

| Recharge when electricity power less than 30% | |

| Instructure | Accum non-return system and vacuum compensation system |

四,The main parts of the machine

1. Fully electric suction cup part:

● The driving computer has a low-voltage over-current protection device to effectively prevent the undervoltage from harming the electrical system.

● High performance hydraulic pumping station

● Equipped with electronic limit switch, it can accurately control the maximum lifting height of the gantry, effectively protect the lifting motor and extend the use of the motor.

life.

● The drive motor has the advantages of strong power, stable performance and low noise.

● Industrial battery for electric suction cup car, equipped with intelligent matching charger, with automatic power-off function, the entire charging

There is no need for on-site monitoring.

2. Suction cup mechanism: The suction cup frame is designed in a rectangular shape and welded by square tube and rectangular tube, which is safe and durable. The suction cups are evenly distributed, so that the force is even and stable after the glass is adsorbed, and the suction cup position can be adjusted in the entire rectangular frame to adapt to different specifications of the glass. Work load 500kg, walking speed manpower control.

3. Suction cup: It adopts fixed-point rubber suction cup, each suction cup can be independently opened and closed to adapt to different specifications of glass; for abnormal power failure, the fixed-point rubber can effectively keep the negative pressure in the suction cup body slowly decreasing, so as to keep the workpiece for a certain period of time. Dropped.

4. Flip mechanism: The hydraulic push rod drives the suction cup holder to achieve 0-90° flip.

5. Rotating mechanism: Use the reducer + gear to drive the suction cup holder to achieve 0-360° rotation.

6. Vacuum part: Adopt imported DC oil-free vacuum pump + check valve + inlet solenoid valve + filter + inlet digital pressure sensor + single suction cup cavity control ball valve to achieve rapid and stable adsorption and release of glass.

7. Alarm system: When the system vacuum pressure drops from the upper limit (85%) to the lower limit (55%), the low pressure alarm is triggered, and the system controls the vacuum pump to automatically replenish the pressure until the upper limit of the vacuum pressure is reached, effectively ensuring the safety of the glass throughout the handling process.

五,Work process

(10) Operate the push rod to retract the suction cup to the suction cup door frame, and then exit the door frame; then move the suction cup to move to the glass to be handled, and repeat the steps 3-9 to complete the glass transportation again.

6,Parameters

| Name | Set | Parameters | |

| 1 | Drive form | 电动 | |

| 2 | Driving style | 步行式 | |

| 3 | Rated load | KG | 1500 |

| 4 | Load center distance | mm | 600 |

| 5 | Lifting height | mm | 3000 |

| 6 | Height when the gantry is retracted | mm | 2000 |

| 7 | Height after suction cup drop | mm | 1000 |

| 8 | Machine length | mm | 2850 |

| 9 | Machine width | mm | 1200 |

| 10 | Turning radius | mm | 2500 |

| 11 | Driving speed Full load / no load | km/h | 5 |

| 12 | Lifting speed Full load / no load | m/s | 0.06/0.13 |

| 13 | Falling speed Full load / no load | m/s | 0.13/0.10 |

| 14 | Maximum climbing capacity Full load / no load | % | 6/15 |

| 15 | Drive motor power | KW | 1.2 |

| 16 | Lifting motor power | KW | 2.2 |

| 17 | Vehicle noise | Db(A) | 70 |

| 18 | Battery voltage / capacity | V/Ah | 24/200 |

| 19 | Charger | V/A | 24/15 |

| 20 | Machine weight | Kg | 1500 |

Related product of LIJINAG GLASS

Automatic Glass Loading Machine for Insulating glass processing

LJASP3525 vertical loading table of insulating Glass Machine

A.Technical performance:

1. All main frames of equipment use quality rectangle steel pipe groups of national standard welded and fitted with bolt.

2.Electric control system of equipment use Schneider brand modules of electric; Program control uses imported SIMENS programmable controller, fitted with touch panel.

3.The machine was designed with concise appearance and conforms to the modern factory with safe signs, and reference to the Euro IEC standard from design until manufacture and installation.

| TECHNICAL DATA | |

| Max glass size | 2500*3500mm |

| 2000*2500mm | |

| Glass thickness | 3-12mm |

| Air source | 0.8Mpa |

| Power | 3P 380V/1P+N 220V 50Hz 38KW |

| Machine Size | 3200*2800*1800mm |

| 2600*2800*1800mm | |

B.Mainly technical parameter:

1.Loading max glass size: L X W = 3500 x 2500 mm

Loading min. glass size: L X W = 800 x 600 mm

Glass thickness: (3-10mm)

2.Dimension of loading table approx.:

L X W X H= 3700mm x 2800mm x 2500mm+ bottom support 530mm(±30mm)

3.The vertical loading table uses Servo motor as drive system and all motors with infinitely variable speeds, the transfer speed of this table is 2-35m/min;Loading cycle time: 35S

4.Adopts full-closed loop control system for accurate positioning for the machine and stable running system;Configuration description

5.The tilting arm horizontal movement controlled by Servo motor and precise gear box, gear rack drive;

6.Lifting structure: Servo motor and precise gear box control and synchronous belt drive;

7.The suction cups frame tilting structure: Servo motor and precise gear box control and crank connecting rod drive;

8.Bottom transfer structure, Servo motor and precise gear box control and chain drive.

9. 4 axis all-digital control with precise positioning and speedy flexibility; All speed can be

adjustable according to production line speed.

10.Super HMI monitor the equipment running status and system parameters; It can set data according to different glass rack height and angle and also pre-setting or recording the current shift of production.

11.Vacuum pump system: highly effective mono-block rotary blade type vacuum pump;

Suction cups: Uses imported PF suction cups ¢120MM type

12. Air compress supply:5—7bar,30L/min;Compressed air supply: 5—7bar, 30L / min;

13.Power supply: 380V, 50HZ, 3 phases,

As professinal Insulating glass machine manufacture in China,except material such as Moleculaer sieve and aluminum spacer and sealant . We are good at develping and producing automatic vertical insulaing glass processing production line ,vertical low-e glass egde deleting machine,automatice robot insulaiting glass production line and so on.

Q: What's the payment term?

A: T/T, L/C and other payment terms could be negotiated.

Q: About this Machine,What’s the guarantee ?

A:1).Our guarantee for 12 months.

2).24 hour’s technical support by email or calling

3).English manual and video tutorial

4).We will provide the consumable parts at an agency price

5).24 hours on line service each day, free technical support.

Q:How about your warranty?

A:Generally, our warranty is one year. Within the warranty period, we can offer technique support, Feedback to you within 24 hours and help you to repair your problem controller freely, even it's not from our factory

Q:Can we visit your factory before order?

A:Yes, we warmly welcome and sincerely invite you or your team to visit our factory, we will help to arrange hotel and pick up you from airport.

Q: What's the delivery term?

A:At most of time, we have stock in the factory. If there is no stock, normally, the delivery time is 15-20 working days after deposit receipt. If you are in urgent need, we can consider making special arrangement for you.

Q:How about the packing for machine, is it safely protected during transportation?

A: Testing Chamber is packed by standard export wooden box for outside package and stretch film for inner package, it won't be damaged. We've delivered many testing machines abroad by sea or by air without damage.