Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

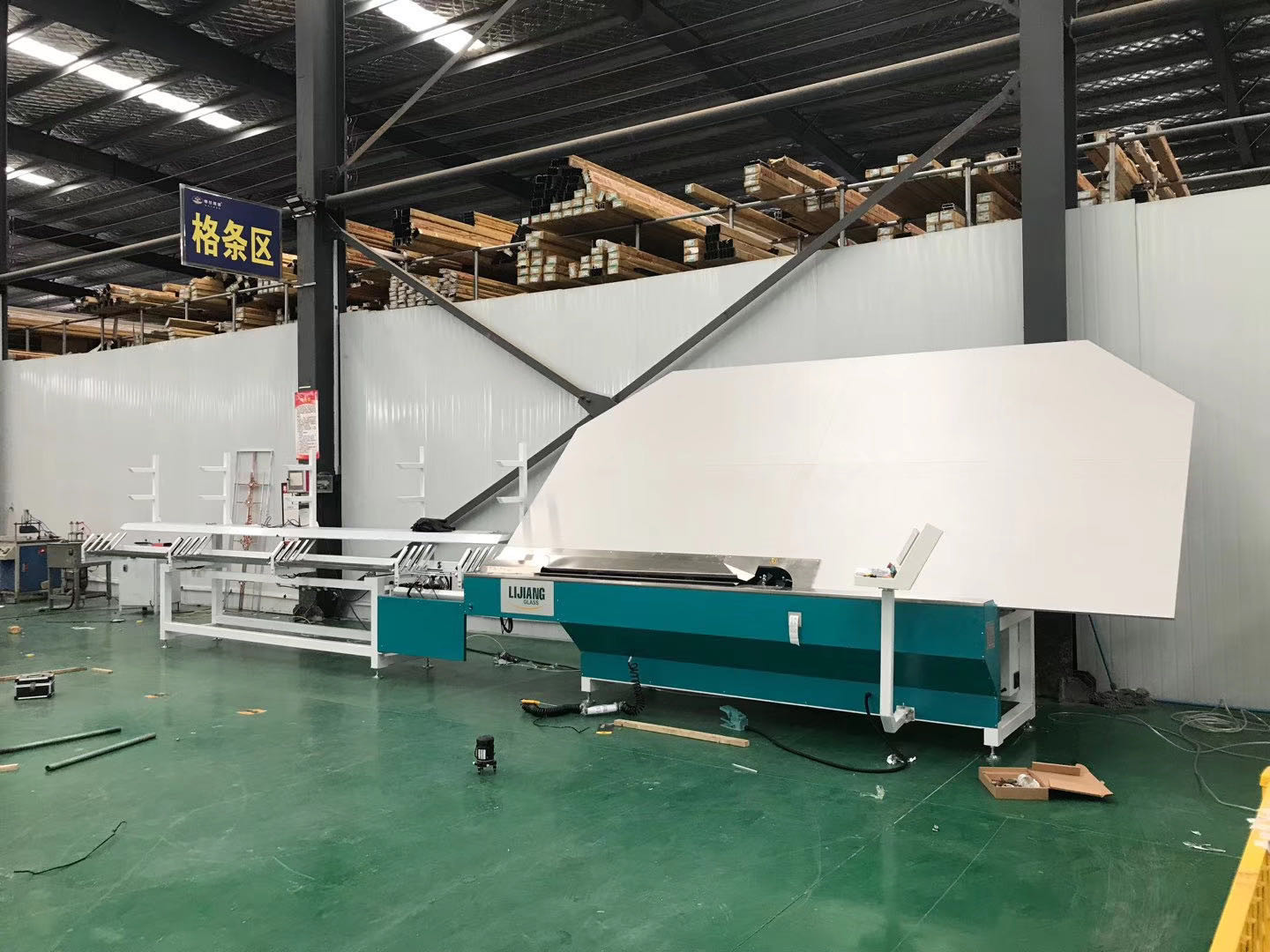

Automatic Aluminum Spacer Bending Machine for Cutting Aluminum Bars with 4 Racks

Automaticaluminum spacer bending machine is used to cut and bend spacer frame for the inner of insulating glass units. Automatic spacer bending machine is one of the auxiliary equipment for making insulating glass. Spacer bender has many optional functions. Such as printing label for spacer's datas,printing logo and date and so on. Also automatic spacer bending machine can bending stainless steel bars and warm edge spacer bars (plastic spacer bars).

Main feature of Automatic spacer bending machine:

• Adopt the control servo feeding system,spacer frame size can be adjusted with an accuracy of 0.1mm/m

• 4 groups of storages (2 or 12 groups of storages can be optional)

• Aluminum spacers are available in sizes of 5.5-26.5mm

• Siemens 1200 PLC control system with fast working speed

• Automatically avoid the pins while bending and cutting

• Bend spacer frames continuously

• Different bending tools for different sizes of spacers

• Pause and Reset device for handling equipment failures

• Bend aluminum spacer, smooth stainless steel, warm spacer

• Connect to ERP system (Optional)

• USB input function, read the excel format file directly

• Automatically drill holes for filling argon gas (Optional)

• Spacer printing code function (Optional)

• Printing label sticker function (Optional)

• Bending shape frame. Using circle wheel device to bend circle frame or frame with circle corners. Min R60, Max R150, spacer sizes: 5.5-26.5mm)

Different sizes of aluminum bars require different size tools (Optional)

Tech Parameters :

| Max. bending size | 2000mm*2000mm |

| Min. bending size | 250mm*200mm |

| Aluminum spacer width | 5.5-27mm |

| Dimensional error | ±0.5mm |

| Angle error | ±1º |

| Processing speed | 17s |

| Air supply | ≥0.65MPa |

| Total power | AC220/380V 50Hz 2.5KW |

| Dimension | 10500mm*2200mm*2600mm |

More details of the automatic spacer bending machine :

Related products

Butyl Extruder Machine LJTB 01

Main feature

• PLC control system, touch screen interface

• Automatically identify the width of aluminum bar, the glue nuzzle can be automatic adjust

• The critical part of the hydraulic system using German imports of components to ensure that the plastic evenly full

• Fast preheat, improve work efficiency

• with preheating function

• With exhaust inflatable function, improve the quality of sealing and save time for plastic

• Quickly coating speed,can up to 47m/min

• Saving the amount of glue

Technical data

| Squeeze pressure | 10-18MPa |

| Temperature | 110~140℃ |

| Aluminum spacer width | 6A - 27A |

| Speed | 5-47m/min |

| Diameter of butyl cylinder | 200mm |

| Air supply | 0.4m³/min |

| Air pressure | ≥0.6MPa |

| Total power | 380V, 5.7KW,50HZ |

| Dimension | 2800×700×900mm(L×W×H) |

| weight | 650kg |

Electrical parameters

| Name | Original | Brand |

| PLC | China | KINCO |

| Valve | German | HAWE |

| Low voltage electrical apparatus | German | SIEMENS |

| Hydraulic and pneumatic supercharging system | German | MAXIMATOR |

| Frequency converter | China | KINCO |

| Pneumatic components | Taiwan | ARTAC |

| Quick exhaust valve/Vacuum generator | Japan SMC | SMC |

| Travel light | Japan | OMRON |

| Optical fiber | Japan | OMRON |