Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

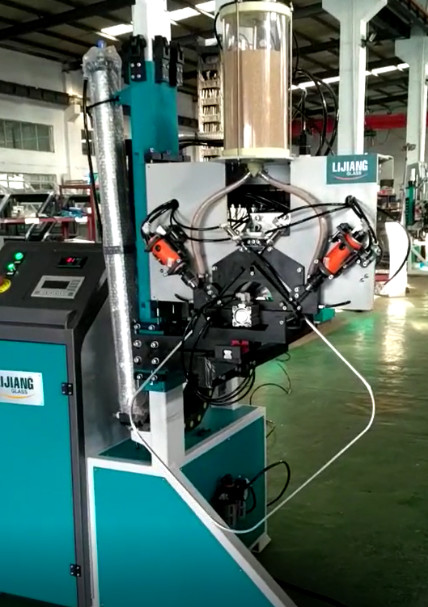

LJGZ2020A Automatic Desiccant Filling Machine

APPLICATION

Desiccant Filling Machine can automatically achieve actions of drilling holes automatically in the spacer frames, filling desiccant and sealant. Desiccant Filling Machine control system adopts Germany Siemens, so the speed of filling is quick and stable operation ensure the valid closure property of sealant. Desiccant Filling Machine improves quality of insulating glass, it’s a necessary equipment in the process of insulating glasses.

Main feature

Germany Siemens PLC control system

Touching screen interface, simple and visible

Fill for bending frame and connected frame

Auto desiccant loading function

Filling time can be adjusted

Auto drilling, filling and sealing function

Directly use big package desiccant, save time for desiccant refill,

increase efficiency

Protect cover for machine head

Distinctive desiccant recycling device

Adopt vacuum pump loading device.

This model has a big barrel to storage desiccant ,no need to put desiccant frequently,increasing efficiency.

It has a vacuum pump to load desiccant,more quickly and improving efficiency.

Pneumatic glass handing manipulator is operated by using compressed air. The device does not use electricity and is safe and reliable, easy to operate.

Main technical parameter

Name | Brand | Name | Brand |

PLC | German SIEMENS | Triplet | TAIWAN AIRTAC |

Lowvoltage electrical apparatus | German SIEMENS | Solenoid valve | TAIWAN AIRTAC |

Sensor | Korea AUTONICS | Gas driller | Taiwan BOA |

Guide | Taiwan TBI | Switch power | Taiwan TEND |

Filling aluminum frame’s maximum size | 2000mm*2000mm |

Filling aluminum frame’s minimal size | 300mm*250mm |

Article aluminum specifications | 5.5-24mm |

Air source | ≥0.65MPa |

Power supply and power consumption | AC220V 50Hz 1.8KW |

Molecular sieve diameter needed | 0.5-0.9mm |

Dimension | 1300mm*1100mm*3650mm |