Jinan Lijiang Automation Equipment Co., Ltd. |

|

Verified Suppliers

|

|

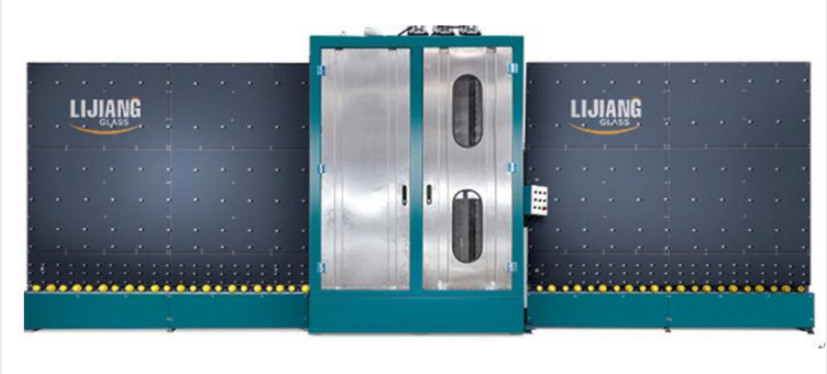

Glass washing machine technical parameters CP-2500A

Cleaning machine for cleaning and drying the upper and lower surface of LOW-E glass

glass washing machine CP-2500A used for cleaning and drying the upper and

lower surfaces of ordinary plate glass and high quality low-e glass,it is composed

of incoming segment, cleaning air-drying segment and outgoing segment.

high efficiency, energy saving 70% efficiency;

2. The rest of the sheet metal parts are sprayed with advanced mechanical

paint or powder;

3. The rubber roller is made of vulcanized rubber with stainless steel shaft;

4. The washing part in contact with water is made of stainless steel;

5. Cleaning department, wind staff overall lift, the maximum lift: 350mm,easy to

clean and maintain;

6. Three pairs of brush(Ø150mm)Stainless steel shaft configuration (low-e glass,

ordinary coated glass and sunshine coated glass can be washed without damaging

the coated surface);

7. Two pairs of special stainless steel aluminum alloy air knife configuration, strong

wind, good air drying effect, with heating system(with temperature control device,

optional opening and closing);

8. The fan is equipped with air filter in the air inlet chamber, with large air volume and

good air drying effect,The whole fan box is installed in the upper part of the workshop,

with the air filter screen on the side for easy inspection and cleaning;

| Maximum glass width | 2500mm (effective maximum: 2650mm) |

| Minimum glass specification | 400mm×400mm (limited to single row on left and right sides) |

| Glass thickness | 3mm-25mm (digital display) |

| Speed range | glass thickness within 3-25mm Vmax=1-12m/min |

| Main drive, brush speed regulation method | frequency control |

| Table height | 900±25mm |

| Total power | 42KW(water-bearing wind heating: 15KW) |

| Water source | self-circulation, tap water (according to civil water standards) and deionized water water supplement (deionized water equipment shall be provided by the buyer) |

| Power source | 380V 50Hz |

| Dimensions (length × width × height) | approximately 6260*4800*3100 |

| Weight | 3940kg |

Jinan Lijiang Automation Equipment Co., Ltd. is located in the beautiful spring

city------Jinan. It is an enterprise which integrated glass processing equipment research and development,

sales and service into a whole. As it is close to Beijing-Shanghai high-speed rail, the transportation is very

convenient.

The company is committed to building high-end insulating glass machinery and equipment by learning from

famous experts, establishing the research and development centers, cooperating with domestic and foreign

well-known enterprises, importing advanced technology and so on. Now, our friendly partners include North

Glass, Xin Fuxing, Yaohua, Dalian Huaying, Beijing Guanhua, Shanghai Hao Jing, Sichuan Li Hehua and

other well-known enterprises. Since the establishment of the company, our products have been exported to

Europe, America, South America, the Middle East, Southeast Asia, India, nearly 30 countries and regions.

At the same time, our company worked with the well-known domestic research institutes, such as the North

China Industrial Group, Shandong University and others, to constantly improve the level of technical research.

So far, we have independently produced the vertical automatic IG production line with filling gas on line, the

vertical IG sealing robot, the automatic spacer bending machine, the automatic desiccant filling machine and

the new fully automatic butyl extruder machine, its technology and quality have reached the highest leading

level in China.

With the rapid development of insulating glass industry, LIJIANG is looking forward to working with you for

win-win situation and jointly creating a new world.