WUHAN GLOBAL SENSOR TECHNOLOGY CO., LTD. |

|

Verified Suppliers

|

|

High-Definition Uncooled VOx Thermal Imaging Module for Industrial Thermography

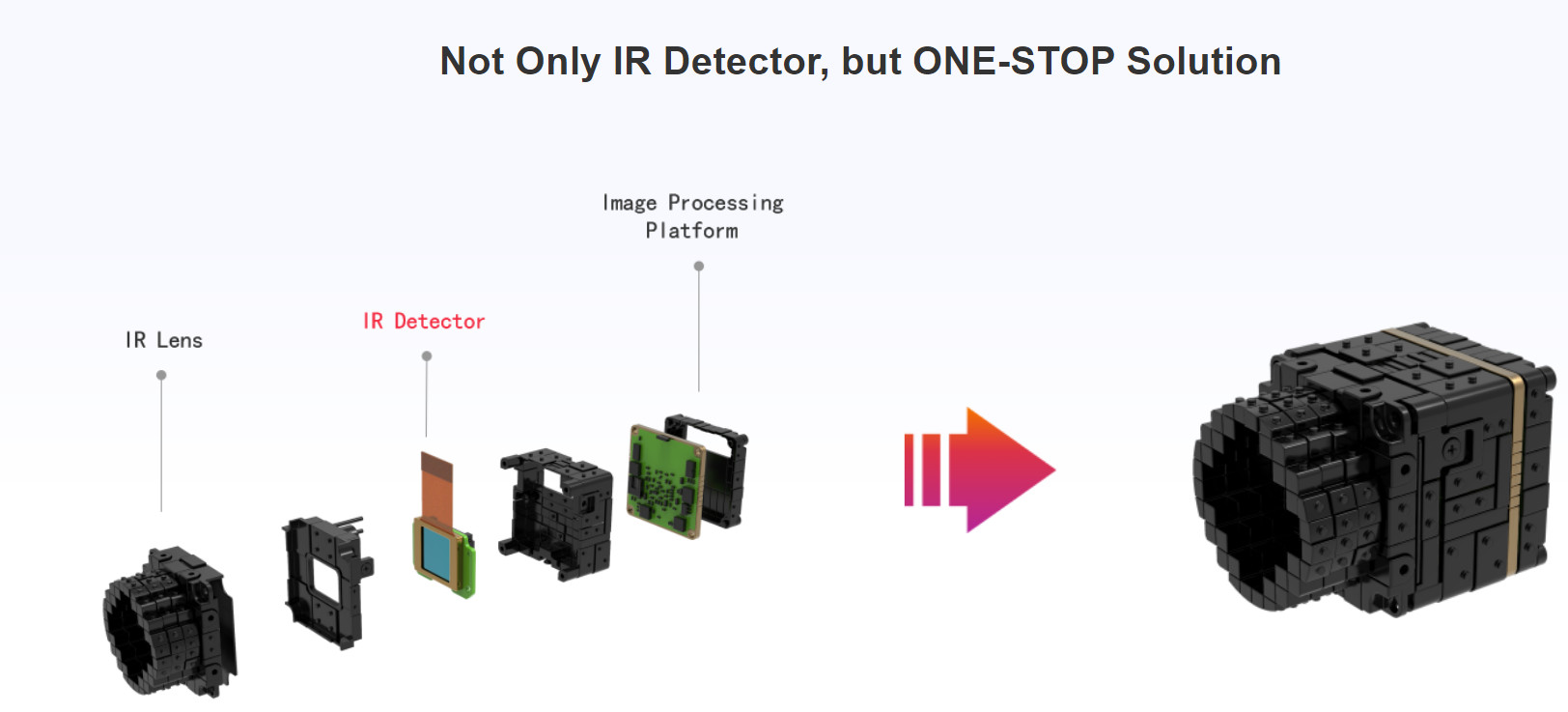

PLUG1212R is one of the PLUG-R series uncooled infrared camera module developed by Global Sensor Technology (GST). It is based on GST1212M uncooled infrared detector with professional signal processing circuit and image processing platform, completely transforms the target infrared radiation into temperature data. Its temperature measurement is available and temperature range can be customizable, which meet the specific requirements of industrial thermography.

The Uncooled HD LWIR 1280x1024/12μm VOx Thermal Imaging Module offers a wide temperature measurement range, enabling diverse applications in fields such as industrial inspection, surveillance, and security. With a temperature range covering both sub-zero temperatures (-20℃) and high-temperature environments (up to 550), this module accommodates the demands of various thermal imaging scenarios.

- Pixel pitch: 12μm

- Resolution: 1280x1024

- Spectra Range: 8μm -14μm

- High Sensitivity: NETD<30mK

- Temperature Range: -20℃~150℃, 100℃~550℃

- Temperature Accuracy: ±2℃ or ±2%

- High reliability & Strong Environmental Adaptability.

| Model | PLUG1212R |

| IR Detector Performance | |

| Resolution | 1280x1024 |

| Pixel Pitch | 12μm |

| Spectral Range | 8~14μm |

| NETD | <30mk |

| Image Processing | |

| Frame Rate | 25Hz |

| Start-up Time | <25s |

| Analog Video | / |

| Digital Video | HDMI/RAW/YUV/BT1120 |

| Extension Component | USB/Camerlink |

| Dimming Mode | Linear/Histogram/Mixed |

| Digital Zoom | 1~8X Continual Zoom, Step Size 1/8 |

| Image Display | Black Hot/White Hot/Pseudo Color |

| Image Direction | Horizontally/Vertically/Diagonally Flip |

| Image Algorithm | NUC/AGC/IDE |

| Electrical Specification | |

| Standard External Interface | 50pin_HRS Interface |

| Communication Mode | RS232-TTL, 115200bps |

| Supply Voltage | 5±0.5V |

| Temperature Measurement | |

| Operating Temperature Range | -10°C~50°C |

| Temperature Range | -20°C~150°C, 100°C~550°C |

| Temperature Accuracy | ±2°C or ±2% (Take the Maximum Value) |

| SDK | ARM/Windows/Linux SDK, Full Screen Thermography |

| Physical Characteristics | |

| Dimension (mm) | 56x56x40.2 |

| Weight | ≤200g |

| Environmental Adaptation | |

| Operation Temperature | -40°C ~ +70°C |

| Storage Temperature | -45°C ~ +85°C |

| Humidity | 5%~95%, Non-condensing |

| Vibration | Random Vibration 5.35grms, 3 Axis |

| Shock | Half-sine Wave, 40g/11ms, 3 Axis 6 Direction |

| Optics | |

| Optional Lens | Fixed Focus Athermal: 19mm/25mm |

The PLU1212R infrared imaging module is widely used in Power Electricity, Machine Vision, Building Inspection, Metallurgical Petrochemical etc.

1.How does an infrared detector work?

Infrared detectors work by sensing electromagnetic radiation in the infrared range. The exact mechanism of detection varies depending on the type of infrared detector.

Thermal detectors work by measuring the temperature change caused by absorbing the infrared radiation. For example, microbolometers consist of a matrix of tiny resistive elements that are sensitive to heat. When infrared radiation is absorbed by the detector, it causes the temperature of the resistive element to increase, resulting in a change in electrical resistance that can be detected and converted into an image.

Photon detectors, on the other hand, work by converting photons from the infrared radiation into electrical signals. Two common types of photon detectors are photovoltaic detectors and photoconductors. Photovoltaic detectors generate a voltage when infrared photons are absorbed, while photoconductors increase their conductivity when photons are absorbed.

Infrared detectors can also utilize other detection mechanisms, such as pyroelectricity, where changes in temperature induce a charge in a material, or thermoelectric effects, where a temperature difference between two materials generates a voltage.

The output signal from the infrared detector can be processed and displayed as an image, which can be used for a variety of purposes, such as thermal imaging in medical or industrial applications, remote sensing of the environment, and thermal scanning in security systems.