Hangzhou Joful Industry Co., Ltd |

|

Verified Suppliers

|

|

Plastic Bopp Waste Shrdder LD/HDPE Bopp Films Crusher Rotary Blades With Sharpener

Waste Bopp Cutting Machine Plastic Paper Films Crusher HDPE/LDPE/PP/PE Shredder Mini Discharge Size To 2mm

Widely Application & High Efficiency

Widely Application

The Joful J series cutting machine is designed especially for soft type materials recycling cutting, and we already apply design patent for this, we are the only manufacture in China supply such design machine

it can be used for almost all soft type materials waste, such as below

| Bags/plastic films/strips | Jumbo bags / PP bags / woven & non-woven bags / plastic bags (PP PE PVC ect.. as long as they are soft bags), plastic films |

| Textile scraps | Quilting edges ,threads, yarns, Clothes (Underwear scrap,jeans,towel,cap scraps,non-woven fabrics,cotton fabrics), Shoes Scraps etc |

| Fibers | Glass fiber, fiber yarn, Coconut fiber, Polypropylene fiber ,polyester fiber, Silk fiber, etc |

| Foams | Sponge/mattress scraps /flexible PU foam / EPS foam / XPS foam /Rock wool foam / glass wool foam / EPE foam / Cotton , silk cotton etc |

| Others | Leather /Carpet / Papers / books /cardboard / plant straw / fish net / ropes etc |

High Efficiency

Our cutting machine working principle is to cut the materials with its sharp blades, like a scissors, adopt rotating twisted the knives, native to the abolition of the traditional reciprocating straight knife board,the application of international leading oblique knob scroll meet the shear design of point moving knife and fixed knife,continuous high-speed shear

|

Take model 2400F for example, the blades length 1200mm, 8 pieces rotary blades, 2 pieces stationary blades, each blades rotating means cutting 16 times, the rotary blades is around 300 round per minute, totally means around 4800 times cutting (see blades design samples below)

|

Description About The Plastic Bopp Cutting Machine

Main Datas

| Factory Scale | 50-60 person |

| RD Team | 5-10 people |

| QC Team | 5 people |

| cutting motor | 8P motor, 5.5/7.5/15/18.5/22/44/66KW |

| transport motor | 4P Inverter motor, adjustable speed |

| blades lifespan | generally 12-24 months |

| blades design | rotary twisted knife |

| working voltage | 220/380/415/440V, customizable |

| power distribution cabinet | independent distribution cabinet |

| Input/output belt width | 330/520/720/1200mm |

| input/output belt length | 1400/3000/4000mm, can be customizable |

| moving knife | 4/6/8 pieces knife |

| fix knife | 2 pieces knife |

| blades materials | alloy tool steel |

| machine materials | carbon steel |

| cutting size | adjustable, 2mm to tens centimeters |

| output | hundreds to 8,000KG per hour |

Quick Details

| Machine Price | Please let we know what materials cutting, and capacity, discharge size request then we can confirm which model you need, and quote you price

|

| Installation | a. Almost whole set machine delivery out, very simple for clients

to install by themselves and we also offer installation drawing

|

| Guarantee | Our guarantee period is 12 months. Within the guarantee period the broken parts (excluding quick-wear parts) can be exchanged with our new parts if it is not caused by human factors, beyond the guarantee period the broken parts dispatched are charged at cost price

|

Maintenance & Safety Tips

Maintenance Tips * Please sharpening the blades regularly according to your suggestion * Please put the machine on an open flat ground, avoid tilt * Running the empty machine for 30 minute after install, check if the machine running ok * Avoid metal materials * Do not try to repair the machine yourself, if any problem, please contact first

|

Safety Operate Tips * When feeding the machine, ,Do not reach hands inside * During the machine is operating, do not reach out to pull out the material at the discharge port! * Please make sure cut off the power when you check and maintenance the machine

|

Blades Sharpening Device Samples

Wooden Box Package Samples

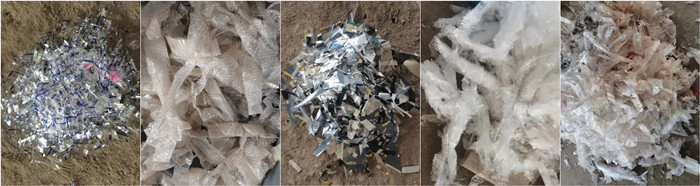

Plastic Bopp Cutting Samples (Customizable)