Xinxiang Techang Vibration Machinery Co.,Ltd. |

|

Introduction

Phosphor / Polishing Powder Vibrating Sieve is a high precision fine powder sieving machine. The fundamental principle of round separator is that the eccentric hammers installed on the top and bottom ends of motor changes the rotation motion of motor to horizontal, vertical and inclined three-dimensional motions, and then passes this motion to screen surface, achieving the purpose of classification, filtering and removal of impurities.

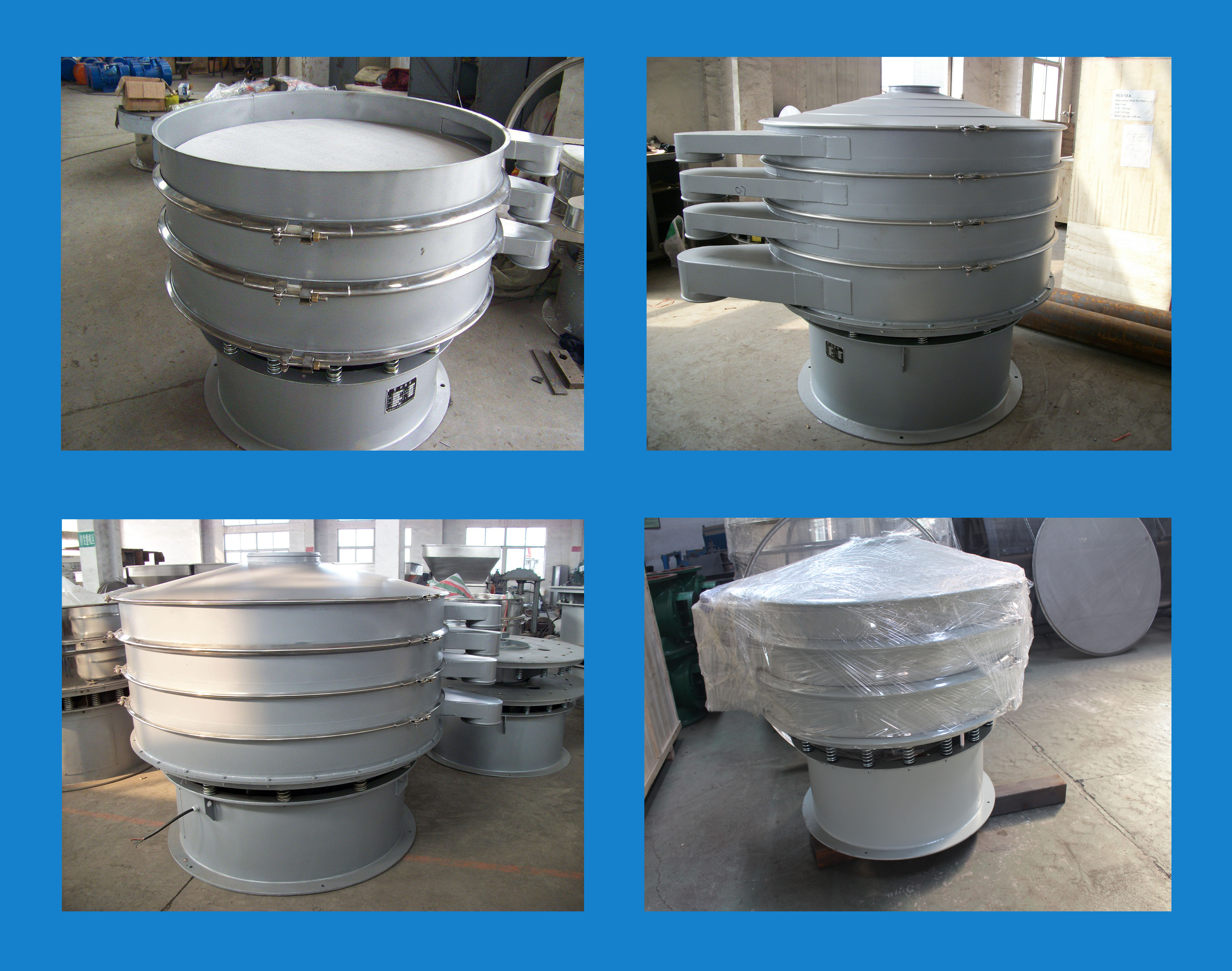

Detail Pictures

Phosphor / Polishing Powder Vibrating Sieve of top cover,

screen frame, screening mesh, clamp, vibrator, vibration motor,

support base, and so on.

Specification

Model | Power | Diameter of screen surface | layer | Mesh size |

| TCXZS600 | 0.37kw | 560mm | 1-5 | 0-500mesh |

| TCXZS800 | 0.55KW | 760mm | 1-5 | 0-500mesh |

| TCXZS1000 | 0.75KW | 930mm | 1-5 | 0-500mesh |

| TCXZS1200 | 1.5KW | 1130mm | 1-5 | 0-500mesh |

| TCXZS1500 | 2.0KW | 1430mm | 1-5 | 0-500mesh |

| TCXZS1800 | 2.2KW | 1730mm | 1-5 | 0-500mesh |

| TCXZS2000 | 2.5KW | 1930mm | 1-5 | 0-500mesh |

Advantages

1. Can be used with single or multilayer screen mesh.

2. Automatic discharge of materials, continuous operation.

3. No dead corner of parts, easy rinse thoroughly and disinfection.

4. High screening precision, high efficiency, suitable for any powder, grain and mucus materials.

5. New grid structure, long service life of screen cloth, only 3-5min for screen replacement.

6. Small volume, less space occupation, easy to move,360 degree adjustment of discharge opening.

7. Fully enclosed structure, no flying dust, no liquid leakage, no blocking of mesh opening, screen can reach 500 meshes, and filter can reach 5 um.