AG Sonic Technology limited |

|

Verified Suppliers

|

|

1440L Industrial Ultrasonic Cleaner 4 Tanks Cleaning Rinsing Drying Filtration

We expertise in Multistage Cleaning Systems with Multiple tanks having Ultrasonic, Jet Spray, Rotating Basket, Dunking, Automatic Material Transfer, Handling system, Filtration, Oil Skimming & Drying as various options. Such machine are used for cleaning of Mold Inserts, Auto-Ancillary Parts, Medical Surgical tools and various other types of components.

Multistage Ultrasonic Cleaning Machine with the ultrasonic power. The product comes with digital timer and controlled thermostat. We offer a unique range of ultrasonic cleaning machines that are highly demanded for their excellent performance and low maintenance. Ultrasonic cleaner is majorly used in cleaning surgical instruments, automobile industry, ancillary industrial products, stationary manufacturers and many more.

Ultrasonics: The ONLY Way to Clean with Confidence

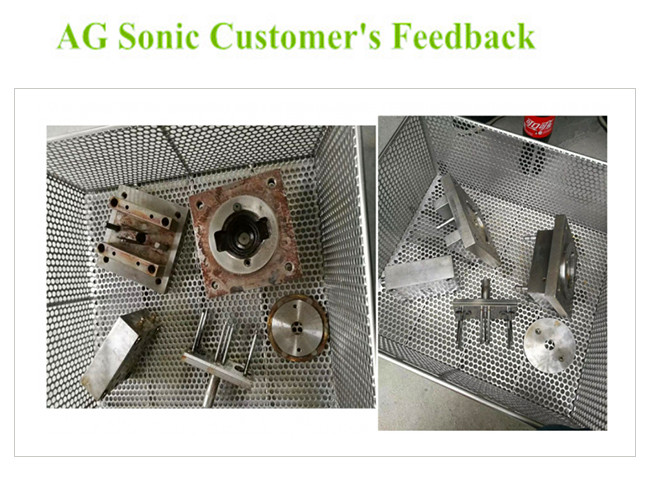

Regardless of the source of the dirt or contamination, AG Ultrasonic Cleaning Systems are designed to accommodate a wide variety of uses in diverse industries. Fast, effective and efficient, our machines will allow you to clean virtually any type of part or component. The following is just a short list of the many different types of items that have been cleaned using our systems.

Saved more than 20 labor hours and minimized employee chemical exposure.

AGSONIC wasn’t the cheapest or the most expensive. They had an excellent product for the money and a commitment to customer service. AGSONIC is very easy to work with, even from 2,000 miles away. The retrofit and all other support needs have been handled in a very responsive manner. AGSONIC ’ dependability and service are part of our operational success. As far as our employees and management are concerned, our AGSONIC units are here to stay. For any future needs, AGSONIC is our 1 choice.

– Customer feedbaack Aerospace.

what the mold itself is made of.

2. When you are ready to clean place the injection molds in the cleaner basket. Take care that they do not contact each other. If you are cleaning large parts you may suspend them in the cleaning solution so they do not contact the tank bottom. Some industrial cleaners are equipped with bottom racks to support products being cleaned.

3. Set the heater to 65 C and timer from 10 to 60 minutes depending on the degree of contamination. Activate the sweep mode to assure uniform distribution of cavitation and promote uniform cleaning then lower the molds into the solution. With experience you will establish optimum cleaning conditions.

4. At the end of the cycle remove the molds and inspect. When satisfied, rinse them with fresh hot water and allow them to dry or blow them dry with compressed air. Note that intricate configurations and cavities may trap water that should be removed by adding an electric drying oven to your setup.

Rinsing tip: You’ll want to thoroughly remove cleaning solution residues. Complex shapes may call for a spray rinse or, in certain cases, rinsing by cavitation in an ultrasonic rinse tank.

How to Clean Large Aircraft Parts

Complex Aircraft Parts require careful cleaning.

Complex Aircraft Parts represent substantial investments by plastic injection molding companies which, in order to protect their investments, must establish cleaning procedures to remove a variety of stubborn contaminants. These include burned on residues, oils, flashing and grease that if allowed to remain will result in product rejection by the quality control department. Hand scrubbing with solvents simply does not do the job. In addition to being time consuming, manual cleaning introduces potential health hazards for personnel and solvent disposal challenges. The solution is using an ultrasonic cleaner instead of scrubbing in a solvent-based parts washer

Why an Ultrasonic Cleaner is Ideal for Aircraft Parts

In three words: thorough, safe and fast. Contaminants missed by manual cleaning are usually those deep in crevices and on other surfaces impossible to reach. Moreover, highly finished mold surfaces can be scratched or otherwise damaged by manual processes. Large molds can be difficult to maneuver, further risking damage during manual cleaning. And the longer it takes to clean the molds the greater the risk of damage.

Ultrasonic cleaning action solves all three issues.

It is thorough because it reaches all mold surfaces immersed in a biodegradable water-based ultrasonic cleaning solution. It is safe because while the cleaning action can be termed “violent” it occurs so fast that highly polished injection mold surfaces are not damaged during the cleaning process. By fast we mean 10 to 15 minutes although large complex molds may require a longer cleaning cycle.

Specification

| Model | T-4120S |

| 1st Tank Volume | 264L Ultrasonic Cleaning tank with filtration cycle system |

| 2nd Tank Volume | 264L Ultrasonic Rinsng tank |

| 3rd Tank Volume | 264L Spray tank |

| 4th Tank Volume | 264L Drying tank |

| 1st tank size | 800X600X550mm |

| 2nd tank size | 800X600X550mm |

| 3rd Tank size | 800X600X550mm |

| 4th tank size | 800X600X550mm |

| Transducers | 60pcs in 1st tank; 60pcs in 2nd tank |

| Ultrasonic Power | 3000W*2 |

| Heating Power of Ultrasonic tank | 6000W*2 |

| Heating Power of Drying tank | 750W |

| Frenquency | 28KHz/40KHz |

| Drying System | 1 set |

| Unit size | 3060*1400*1150mm |

| Packing size | 3120*1460*1270mm |

| Timer | 0~99 minutes adjustable |

| Heater | Room temperature~99℃ adjustable |

| Material | SUS 304 default, can be SUS 316 |

| Power Supply | AC 220V 3 phase ; AC 380V 3 phase |

| N.W. | 500G |

| G.W. | 550KG Wrapped by film in wooden case |

| Lead time | 18 working days |

| Warranty | 1 year warranty period, technique support all time |

| Certificates | CE, RoHS, FCC |

| Advantage | Filter the dirty water; keep the water clear in tank; lower the frequency of changing water |

Removes brake dust, rust, grease and all dirt and gives surface without grease and fingerprint

Clean your clients' wheel easier and more efficently than ever before with this ultrasonic cleaning

system! This technology can be adapted to clean other parts and accesories like engine parts,

gearbox parts, etc. It saves you time and money! After the cleaning it's much easier to find any

hidden damages on the surfaces!