Xi'an Longjoy Foreign Trade Co.,Ltd |

The pipe cap is a pipe fitting used to close the pipeline. The form of blind plate is similar, but the blind plate can be removed for sealing, while the welded pipe cap can not be removed. The pipe cap includes convex pipe cap, cone shell, variable diameter section, flat cover and shrink mouth design. The diameter, size and span of pipe cap are very large, and they are widely used in our production and life. The small cap is installed on the small volume container, and the sealing effect can be maximized by using the cap. However, it needs to be known that the cap is different from the conical head when it is used. The head belongs to the small head, and there is a big difference when it is installed. When installing medium-sized or large-scale pipe caps, the cold installation method is generally used, that is, the solidification installation method is directly used. However, this installation technology cannot be used for small-scale heads, because many times, small-scale heads need to be repeatedly disassembled, and another installation method is needed. There are two main processes for the manufacture of Socket welded pipe cap: hot spinning and hot stamping.

The principle of hot spinning is that the temperature of metal material is inversely proportional to its strength. With the increase of temperature, its strength will decrease. Hot spinning is to use this principle to realize the forming of the pipe cap. Use the heating device to locally heat the parts of the head that need to be spun. When the temperature reaches a certain value, start spinning. In the process of spinning, continue to heat the parts of the head that need to be deformed until the head is spun into shape. The heating process of hot stamping is completely opposite to that of hot spinning. Hot stamping is heating to above 900 ℃ in the furnace and then moving to the stamping machine for stamping. Its temperature is a constant cooling process, and the general specification requires that the final pressing temperature must be higher than 680 ℃. Because it is difficult to grasp and measure in the process of concrete operation, there are often some over standard conditions.

Material: carbon steel

Size range: DN 6-100

Pressure range: 3000, 6000

Thickness: XXS,Sch80,Sch16LB

Surface treatment: anti-oil; anti-painting

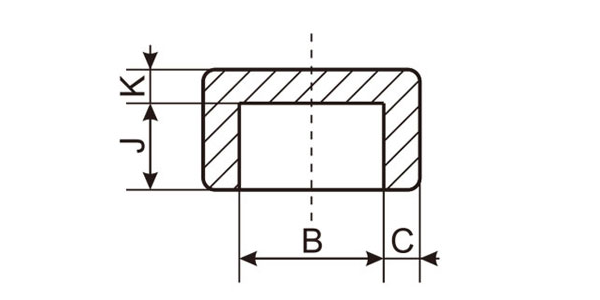

| Nominal Diameter | Depth of Socket | Dimension of Socket | Wall Thickness | End Wall Thickness | |||||

| Cmin | Kmin | ||||||||

| DN | NPS | Jmin | d1 | 3000 LB | 6000 LB | 9000 LB | 3000 LB | 6000 LB | 3000 LB |

| Sch80 | Sch160 | XXS | Sch80 | Sch160 | XXS | ||||

| 6 | 1/8 | 10 | 10.7 | 3.2 | 3.5 | - | 5.0 | 6.5 | - |

| 8 | 1/4 | 10 | 14.1 | 3.3 | 4.0 | - | 5.0 | 6.5 | - |

| 10 | 3/8 | 10 | 17.5 | 3.5 | 4.4 | - | 5.0 | 6.5 | - |

| 15 | 1/2 | 10 | 21.8 | 4.1 | 5.2 | 8.2 | 6.5 | 8.0 | 11.0 |

| 20 | 3/4 | 13 | 27.4 | 4.3 | 6.1 | 8.6 | 6.5 | 8.0 | 12.5 |

| 25 | 1 | 13 | 34.2 | 5.0 | 7.0 | 10.0 | 9.5 | 11.0 | 14.0 |

| 32 | 1.1/4 | 13 | 42.9 | 5.3 | 7.0 | 10.6 | 9.5 | 11.0 | 14.0 |

| 40 | 1.1/2 | 13 | 48.3 | 5.6 | 7.8 | 11.2 | 11.0 | 12.5 | 16.0 |

| 50 | 2 | 13 | 61.1 | 6.1 | 9.5 | 12.2 | 12.5 | 16.0 | 19.0 |

| 65 | 2.1/2 | 16 | 76.9(73.8) | 7.7 | 12.5 | 16.0 | 19.0 | - | |

| 80 | 3 | 16 | 89.8 | 8.3 | 13.8 | - | 19.0 | 22.0 | - |

| 100 | 4 | 19 | 115.5 | 9.4 | - | - | 22.0 | 28.5 | - |

1. Generally, spherical caps are used for pressure vessels, which are used in high-pressure equipment or non-ferrous metal equipment of medium and high pressure.

2. There is a large bending stress in the dished cap, while the ellipsoidal cap is mainly membrane stress, so it is not ideal in engineering application.

3. During welding, pay attention to the protection of the pipe cap surface, timely clean the weld, heat affected area and surrounding welding slag, spatter and pollutants, and conduct Pt inspection and surface pickling.

4. Prevent the surface of carbon steel head from collision and scratch. Prevent direct contact with carbon steel and avoid iron ion pollution.

5. Avoid forced assembly welding. The structural design shall prevent excessive restraint stress.

6. The chloride ion content of water for hydrostatic test shall not be more than 25mg / L, and it shall be dried in time after the test.

1. Sanitary, non-toxic, this product is a green building materials, can be used for pure drinking water pipeline system.

2. Heat resistant, under the specified long-term continuous working pressure, the water temperature transported by the pipeline can reach 95 ℃.

3. Corrosion resistance, no scaling, can avoid pipe scaling and clogging, basin, bathtub yellow spot rust worry.

4. Heat preservation and energy saving, thermal conductivity is much lower than that of metal.

a. Plastic bubble bag package b.Wove bag package c.Pallet d. Customized

Our factory have high ability for production, the delivery time is 45days for small quantity, or if you are hurry for that, we can arrange and meet your shipping date.