Chengdu Yongyi Pump Industry Co., Ltd. |

|

Double Casing High Pressure Slurry Pump , End Suction Mud Pump Centrifugal Sludge Pump

Slurry Pump Components Description

Impeller

The impeller, either elastomer, is the main rotating component

which normally has vanes to impart the centrifugal force to the

liquid, usually made of high chrome material. Cast-in impeller

threads are better suited for slurries.

Casing

the structure is volute type split outer casing, contain the wear

liners and provide high operation pressure capabilities, which

efficiency is mouch higher than semi-volute or concentric

structure.

Shaft and Bearing Assembly

A large diameter shaft with a short overhang minimizes deflection

and vibration. Heavy-duty roller bearing are housed in a removable

bearing cartridge.

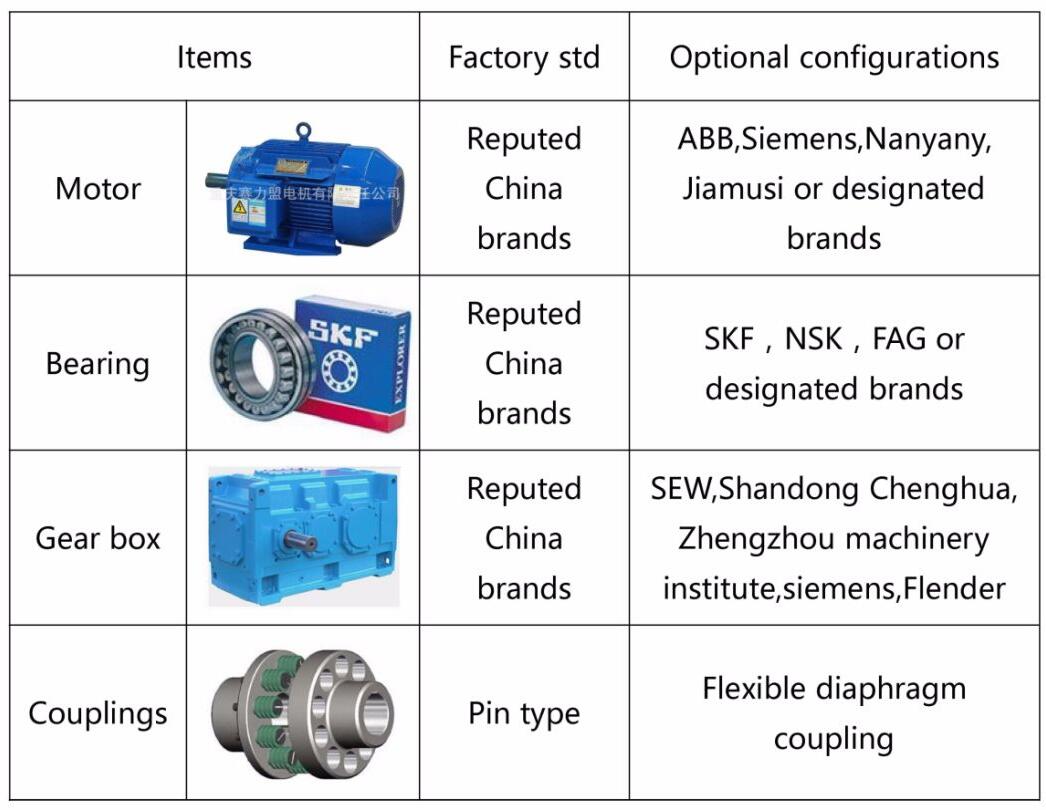

Drive Type

This series pumps are always driven by electric motor. 220V/380V/440V etc are all available. Normal motor, high efficiency motor and explosion-proof motor all can be choosen.

Main Features

1) Good passing ability:gravel pump max passing particles size is 380mm;

2) Widely application: all slurry, mud and bad corrosive medium can be transported, widely used in industry of mining, electrical power, metallurgy,coal, construction etc.

3) High concentration, volume concentration reach to 60%, weight concentration reach to 70%;

4) Comprehensive performance is good, high head: long distance and high head transportion, single set head can reach to max 520m, and can be used in series to satisfy much higher head requirements;

6) High flow rate capacity: can be reached 3400m3/h;

7) Diameter size:outlet size from 1" to 22"

Application

|

Specification Data

| Discharge Size:20mm~350mm | NPSH:0m~3m |

| Inlet Size:32mm~400mm | Allowed Max Particle Size:20 mm |

| Capacity:4 ~ 3000 m³/h | Seal Type:step-down dynamic seal |

| Head:10 ~ 130 m | Pump Weight:up to 3000kg |

| Maximal Efficiency:70% | RPM:1450 r/min |

Parameter

Model | Clear Water Performance | ||||

Flow Q

| Head | Rotating speed n | Shaft power (Pa) | Effectiveness η | |

(m³/h) | m | r/min | kw | % | |

300ZJ(G)-I-A | 704-2333 | 30.6-80 | 490-980 | 135-505 | 66-81 |

250ZJ(G)-I-A | 405-1480 | 29.1-128.7 | 730-980 | 58.3-652 | 54-76.9 |

200ZJ(G)-I-A | 256-976 | 28-133.7 | 730-980 | 60.3-448.1 | 50-79.6 |

150ZJ(G)-I-A | 164-600 | 19.4-91.2 | 730-980 | 15.8-161.5 | 46.1-74.6 |

100ZJ(G)-I-A | 86-360 | 16-100.2 | 980-1480 | 6.7-105.5 | 58.7-70.4 |

80ZJ(G)-I-A | 60-242 | 15.7-109.8 | 980-1480 | 5.5-115.9 | 38.8-66.7 |

65ZJ(G)-I-A | 28-69 | 11.2-34.8 | 960-1460 | 1.7-10.8 | 54.2-63.5 |

50ZJ(G)-I-A | 31-111 | 34.3-110.7 | 970-1480 | 9.7-66.9 | 12.2-45.1 |

40ZJ(G)-I-A | 9-23 | 9.1-44.6 | 1400-2900 | 0.3-4.7 | 33.2-52.4 |

Production Process

Our Service

Before-sale service

Product introduction, technical exchange, non-standard product design, problem explanation.

In-sale service

1. Honoring contracts, ensuring on-time delivery, keeping contact

with users at any time.

2. For special or complicated [products, arrange persons to provide

the users with training and guidance at the product use,

troubleshoot, adjustment and repair.

After-sale service

1. Offer a warranty for 12 months from the date of ex-works, with

return, replacement and repair available.

2. During the use of products, carry out a periodic organization of

the personnel in charge of the technique, quality inspection and

service to contact the users to get the feedback on the quality,

conditions of use, comments on improvement etc. so as to further

enhance the quality.