|

|

[China]

Trade Verify

Address: No. 27 Fenglin Road, High-tech Zone, Zhengzhou 450001, Henan, China

Contact name:Anna

Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

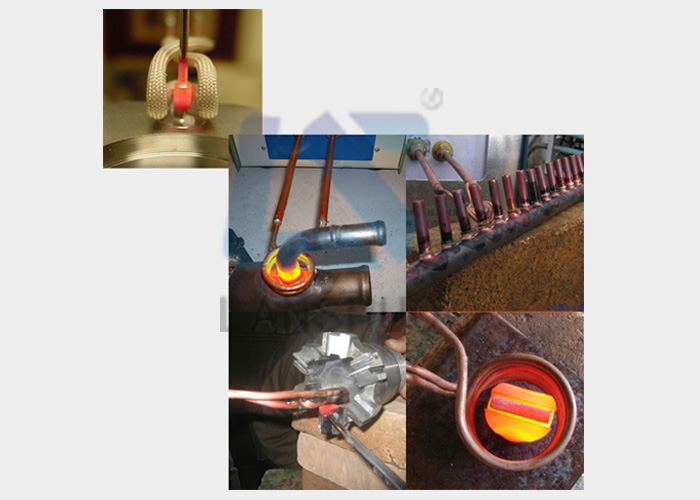

30kw Portable Metal Tube induction welding machine

1.Induction welding machine applications as follows:

1). the welding of metal cutting tools: diamond tools, grinding,

drilling, alloy saw blade, carbide turning tool, milling cutter,

reamer, planer, drill bits and other woodworking welding;

2). the welding of metal mechanical parts: hardware bathroom

products, refrigeration, copper fittings, lighting accessories,

precision mold parts, metal handle, mixer, alloy steel and steel,

steel and copper, copper and copper equivalent or dissimilar metals

metal silver soldering, brazing;

3). composite solder pot is mainly used for round, square and other

shaped surface stainless steel pot with three-layer aluminum

brazing can also be used for other flat metal brazing.

4). an electric kettle (electric coffee pot) of hot plate welding

is mainly used for stainless steel flat-bottomed, aluminum heating

pipe with a variety of shapes between the brazing.

2. Technical Parameters of LSW-30 Induction Welding Machine:

| Model | LSW-30 |

| Working Voltage | 380V, 50/60HZ |

| Max input power | 30kw |

| Oscillation frequency | 25-40KHZ |

| Duty cycle | 100% |

| Cooling water flow | 25L/Min,0.15-0.2MPa |

| Weight | 48kg |

| Dimension (L*W*H ) | 690*290*600mm |

| Material | stainless steel |

| Color | support customized |

| Usage | metal heating, brazing,melting etc |

3. Induction Welding Machine Application:

(1) Metal Tube Welding: such as copper tube, steel tube, and aluminum tube’s butt welding,

plug welding and welding sets.

(2) Alloy Cutter Welding: such as alloy turning, milling cutter, planer, saw blades, reamer,

boring knife.

(3) Carbide Saw Blade Welding: diamond saw blade welding, marble saw blade welding,woodworking saw

blade welding, cut grass piece of welding, cut aluminum welding

(4) Metal Welding: such as: towel rack, soap nets, towel holder, auto-accessories,

moto accessories, metal terminals, hardware pieces, electric

heating tube parts and fasteners.

(5) Heat treatment: heat treatment of small parts

(6) Melting: small amount metal melting, such as: 0.5KG--2KG gold, silver,

copper, brass, steel, stainless steel, aluminum , aluminum alloy

melting.

4. High frequency induction heating brazing welding machine:

1. It adopts the most advanced MOS, IGBT frequency conversion

control technologies to ensure the high efficiency and maximum

output power.

2. It has the constant current and power control function, which

can significantly optimize metal heating process, realize the high

efficient and fast heating and bring into play the superior

performance of the products.

3. It has the function of three-stage time setting represented by

heating-heat preservation-cooling. Furthermore, the power for

heating and heat preservation is available for independent

regulation, which can facilitate the heating and heat preservation,

which is applicable to places requiring bulking and repeated

heating.

4. A maximum ten types fault protection and display of

over-current, over-voltage, water shortage and phase missing can

provide higher reliability and durability.

5. It is safe and reliable, and requires no equipments of ten

thousand voltage, and thus can ensure the safe operation.

6. It is available for ultraviolet temperature detection, which can

realize the automatic control of temperature, improve the heating

performance and simplify the manual operation.

5. Advantage of induction brazing machine:

A. Fast Heating: the quickest heating speed is less than 1 second,

and the heating speed adjusting and control are available.

B. Widely Applicable: it can be used to heat various metal parts.

C. Low Power Consumption: compared with traditional heating method,

the heat efficiency can be over 95%.

D. High Effectiveness: fast warming and uniform heating, reduce the

workpiece oxidation and deformation.

E. High Efficiency: can do 24 hours continuously working with

comprehensive full load design.

F. Small Footprint & Light Weight:save space of workshop and

easily moved.

G. Easy Operation: easy installation and operation, which can learn

in only several minutes. It can be started to peform on condition

that water and power supply are available.

H. Environmental Friendly: free of noisy, exhaust gas and dust, so

can provide a better working surroundings