Zhengzhou Lanshuo Electronics Co., Ltd |

|

Verified Suppliers

|

|

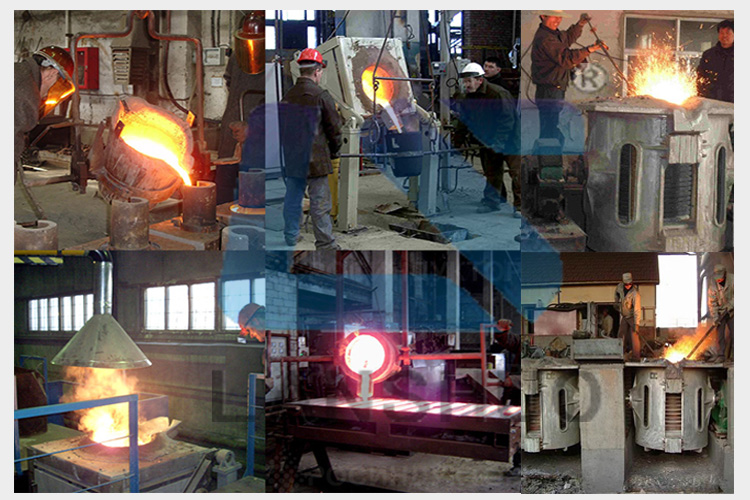

1. Brief Introduction of Medium Frequency Induction Melting Furnace:

Induction electric furnace steelmaking is more in line with environmental protection requirements,while electric arc furnace steelmaking produces a large amount of exhaust gas, waste residue and noise, and has high energy consumption.

An induction melting furnace is an electrical furnace in which the heat is applied by induction heating of metal.Induction melting furnace capacities range from less than one kilogram to one hundred tonnes, and are used to melt iron and steel, copper, aluminium, and precious metals.

2. Technical Parameter of Large Induction Melting Furnace:

| Model | KGPS-0.5T/400KW |

| Rated Power | 400kw |

| Rated Capacity | 0.5T |

| Matching transformer's capacity | 500KVA |

| Voltage | 380V, 50/60HZ |

| MF Frequency | 2000HZ |

| Medium Voltage | 750V Phase |

| DC Voltage | 500V Phase |

| DC Current | 800A Phase |

| Rated Temperature | 1600°C |

| Closed Loop Water Cooling Tower | LSN-30B |

3. Large Induction Melting Furnace Application:

(1) iron, pig iron, cast iron;

(2) steel, stainless steel, cast steel, carbon steel and bearing steel;

(3) gold, silver, platinum;

(4) copper, brass, bronze;

(5) aluminum, aluminum alloy;

(6) zinc, lead, tin, magnesium, nickel, titanium.

4. Feature of Large Induction Melting Furnace :

The intermediate frequency induction melting furnace uses induction

heating to heat the metal work-piece itself. At the same time, the

furnace body of the intermediate frequency induction smelting

furnace is made of thermal insulation materials, so the heat loss

is smaller. The non-contact heating of the metal also reduces the

energy loss, and the thermal efficiency is as high as about 75%.

Under the same conditions, it can save energy by 20%-60% compared

with traditional heating equipment. It also greatly reduces the

preheating time before metal smelting. . Since the furnace body

itself does not produce high temperature during the heating

process, the service life of the smelting furnace is prolonged and

maintenance costs are reduced.

The advantage of the induction melting furnace is a clean, energy-efficient and well-controllable melting process compared to most other means of metal melting.

medium frequency induction melting furnace heat metal work-pieces

by induction heating method. at the same time,furnace body is made

of thermal insulation materials,heat loss is much less.

the non-contact heating of metal also reduce the energy

loss,thermal efficiency is up to 75%. under the same conditions,it

is much more energy-saving by 20%-60% than traditional heating

equipment, and it also reduces preheating time before metal

melting. During heating process,furnace body itself does not

produce high temperature,so it can prolong melting furnace's

service life and reduce maintenance costs.