Dongguan Kingpo Technology Limited |

|

Verified Suppliers

|

JIS ASTM Salt Spray Corrosion Test Chamber For Surface Treatment

Salt Spray Chamber For Corrosion Resistance Test For Surface Treatment Of Various Materials

JIS / ASTM / CNS Ingress Protection Test Equipment Salt Spray Chamber 2000x800x600mm

Product Introduction:

The salt spray test machine is used for the surface treatment of various materials, including coatings, electroplating, organic and inorganic coatings, anodizing, anti-rust oil and other anti-corrosion treatments to test its corrosion resistance, thus establishing the quality of the product.

Inner chamber introduction:

Spray tower | The built-in glass nozzle is placed inside the spray tube, and the spray is guided through the tower tube and dispersed into the test chamber through the cone disperser. |

Spray regulator | Adjust the quantity of spray by increasing or decreasing it. The preheating tank of salt water is at the bottom of the spray tower. Its salt water is injected into to tank from refill bottle. The water level is controlled by float ball automatically. Drain outlet for cleaning is stuck by silicone cork at the bottom of the tank. |

Collector | The spray from the spray nozzles will fall into a 80cm2 V-shape container in free fall way and will be led to measure cup by tube. |

Rack | The rack is made of plastic-steel. The maximum rack load shall be 2kg for single lading point or 10kg for scattered lading points. |

Heating tank | The U-shaped heating tube is equipped with a heating tank for the test chamber, which is used for heating water to keep the temperature in the test chamber stable, and its function is heating and heat preservation. |

Metering tube | Collect the spray volume for each test. |

Water-sealed tank: | A 5cm wide water tank around the transparent acrylic cover is sealed with water to prevent salt spray from leaking. |

Saturated air pail | It is placed inside the control box, and its function is to heat and humidify the air through this pail, so that the air reaches the saturated humidity and sprays. |

Test inlet | Automatically replenish the salt solution of the brine preheating tank. |

Chamber cover | A roof-like transparent top with 100º angle which cover the machine testing body and unify it. |

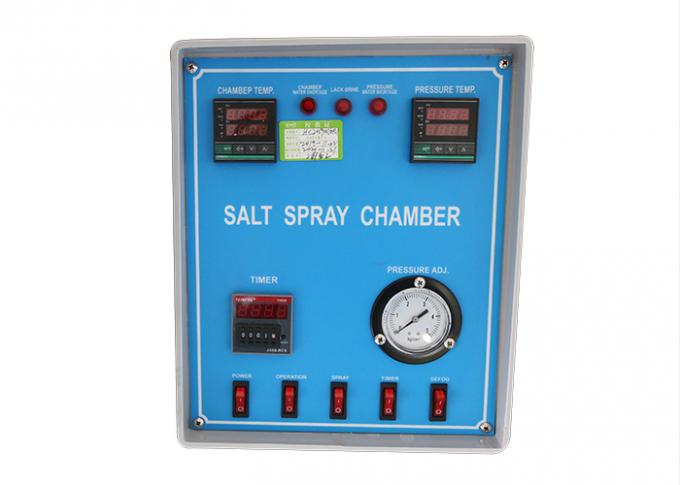

Adjust press valve | This valve is used to adjust the spray pressure. It can only be adjusted when the spray switch is turned on and the machine is operating normally (test conditions 1Kg / cm²) |

Pressure meter | It shows the pressure of the air from the saturated-air pail to the nozzle (testing pressure: 1kg/cm2) |

Exhaust pipe | The diameter of the exhaust pipe is 48mm. The spray in the chamber is discharged through this hole. When testing, it is best to connect a hose to lead the spray to the outside. Do not block or have water accumulation. |

Chamber drain valve | The red ball valve is equipped with a 4-point PVC water pipe. This valve is opened when the chamber water is dirty and the chamber water needs to be replaced. |

Test chamber temperature controller | Control the temperature in the chamber according to standards, the temperature of the chamber is controlled at 35 ℃. |

Saturated-air pail temperature controller | Control the temperature in the saturated-air pail, another safety protection device, the temperature safety set value is 5 ° C higher than the actual temperature. (Located in the control box) |

Timer | Set testing time from 0.1s to 9999hr and stop the machine when the time expires. |

Salt water spray test | 35℃ for test chamber controller and 47℃(40℃-50℃)for saturated-air pail controller. |

Corrosion-resistant test | 50℃ for test chamber controller and 65℃(60℃-70℃)for saturated-air pail controller. |

Power switch | Illuminated rocker switch. Control the mains of the whole machine. |

Operation switch | Illuminated rocker switch. Control the water-heater tank and the heater system of saturated-air pail. |

Timer switch | Illuminated rocker switch. Control the power of timer. |

Spray switch | Illuminated rocker switch. Control the spray system. |

Defogger switch | Illuminated rocker switch type. Control the defogger system and get rid of the salt spray inside the box. |

Chamber water shortage lamp | The light will be turned on and the operation will be stopped when the water level in the chamber is lower than the limit. |

Pressure water shortage lamp | The light will be turned on and the operation will be stopped when the water level in the saturated-air pail is lower than the limit. |

Lack brine lamp | The light will be turned on and the operation will be stopped when the water level of preheating tank of salt water is lower than the limit. |

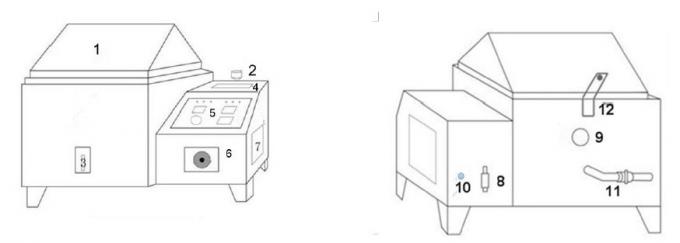

Product front view A: Product back view B:

A: | B: |

1.Test chamber | 8.Compressed air inlet |

2. Manual water filling place for pressure pail | 9.Exhaust |

3.Metering tube | 10.Power supply 230V |

4.Brine inlet | 11.Chamber drainage valve |

5.Control plane | 12.Cover support frame |

6. Adjust press valve |

|

7.Control box door |

|

Technical Parameters:

Model | HH0813D |

Inner chamber size (mm) | 2000x800x600mm(W*D*H) |

Outer chamber size (mm) | 2300x1100x1400mm(W*D*H) |

Test chamber temperature | Salt water test method (NSS ACSS AASS)35℃±1℃/ corrosion resistance test method(CASS)50℃±1℃ |

Pressure barrel temperature | Salt water test method(NSS ACSS AASS)47℃±1℃/ corrosion resistance test method(CASS)63℃±1℃ |

Salt concentration | The concentration of sodium chloride 5% or the 5% concentration of sodium chloride add 0.26g per liter of copper chloride (CuCl2 2H2O) |

Compressed air pressure | 1.00±0.01kgf/cm² |

Spray amount | 1.0~2.0ml/80cm²/h (collecting at least for 16 hours, take the average) |

Relative humidity of testing chamber | More than 85% |

Acid value PH | 6.5~7.2 3.0~3.2 |

Spray mode | Programmable spray (including continuous spray and intermittent spray) |

Meet the standards | JIS, ASTM, CNS |

Power supply | 230V, 60Hz |

Picture View: