Guangdong Hwashi Technology inc. |

|

Verified Suppliers

|

|

HWASHI Stainless Steel Furniture /Chair Frame Welding Station 6 Axis Robot Welding Machine

Desription Of The Chair Welding Station

The Chair Frame MIG Welding Robot is designed for welding the chair. It adopts 6 axis robot with MIG welder for automatic welding and uses cylinder to clamp the work piece and the lever principle to fix the product, which ensure the location requirement for robotic automatic welding and each position could be welded. And the fixture is designed with 2 sets in order to meet the production requirement. One set for loading, one set for welding.

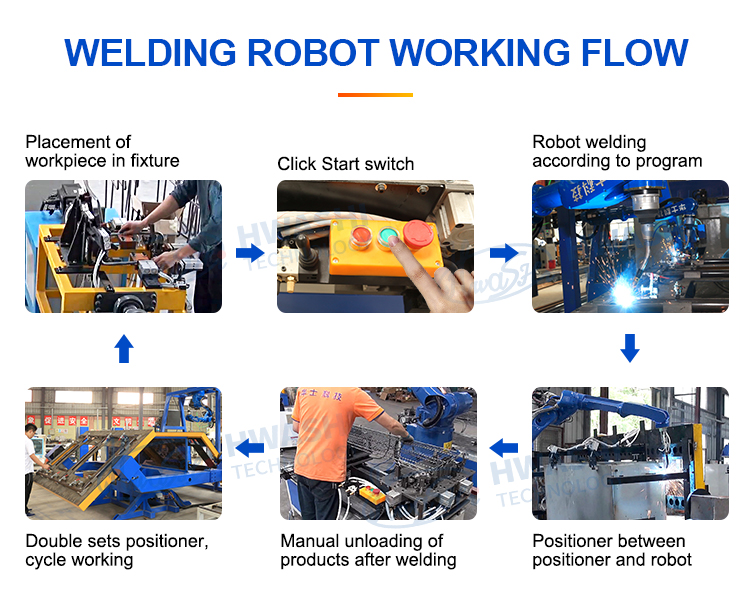

Workflow Of The Chair Welding Station

1) Manual loading of the workpiece to the fixture in Station 1 fixed table;

2) Start welding;

3) The robot and welding machine will do welding on the workpiece according to the presetting program;

4) Welding completed;

5) While the station 1 is being welded, station 2 is being loaded and fixed the work piece synchronously. Two stations work alternately.

6) Cycle working

.

.

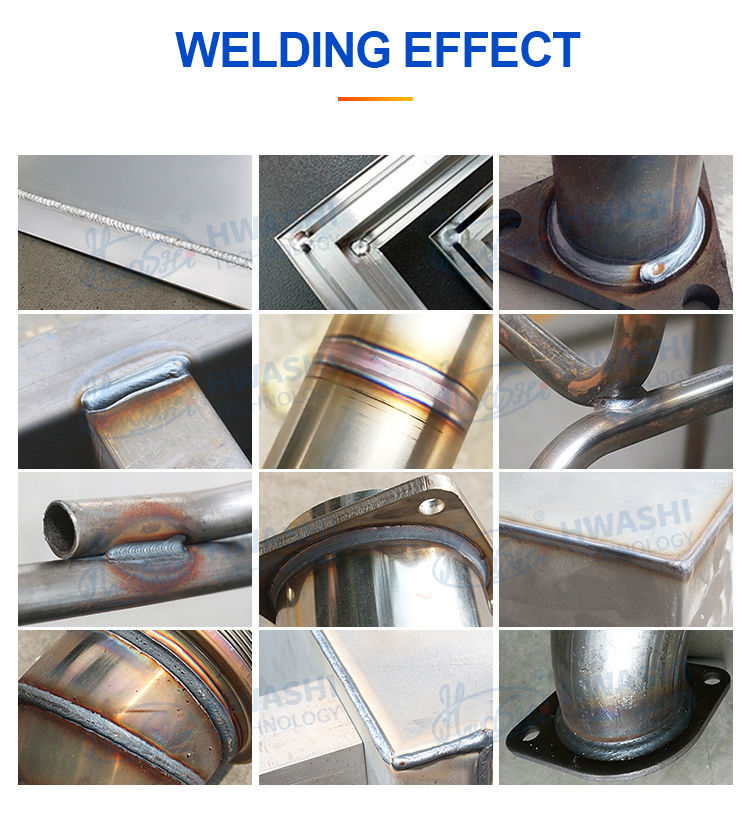

Application And Samples Of The Chair Welding Station

Other Equipment Related To The Chair Welding Station

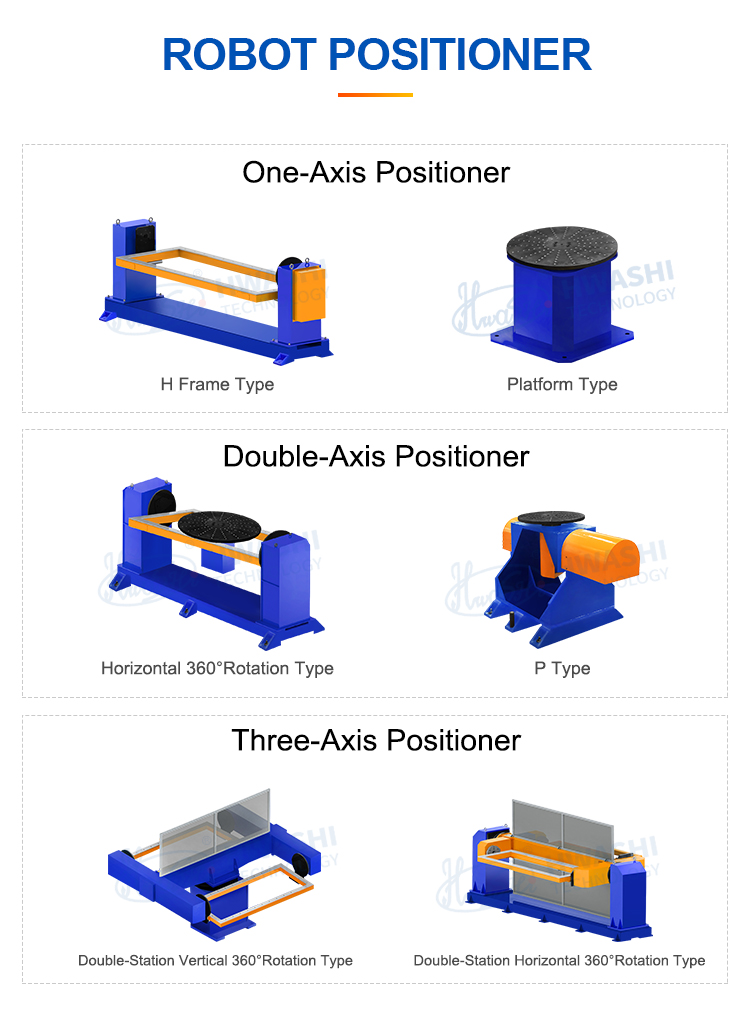

Welding positioner

1. It can work in coordination with the robot to ensure constant

welding speed and attitude and provide higher welding quality.

2. Use imported servo motor with high precision reducer, high rotary accuracy, accurate positioning, and strong bearing capacity.

3. By turning the workpiece fixed on the worktable to the required welding angle.

Provide the 7th axis of the customized machine

1. Increase the working range of the robot to solve the disadvantages of limited working range caused by limited movement range of the robot.

2. Robot slide rail installation: the robot can walk alone or walk with matching welding power supply and robot control cabinet as a whole according to the on-site working conditions of customers.

3. Special protective mechanism to prevent welding spatter or dust in the air which will cause bad impact of precision parts.

4. In order to adapt to the different conditions of different customers, be able to do different configuration and installation for customer.

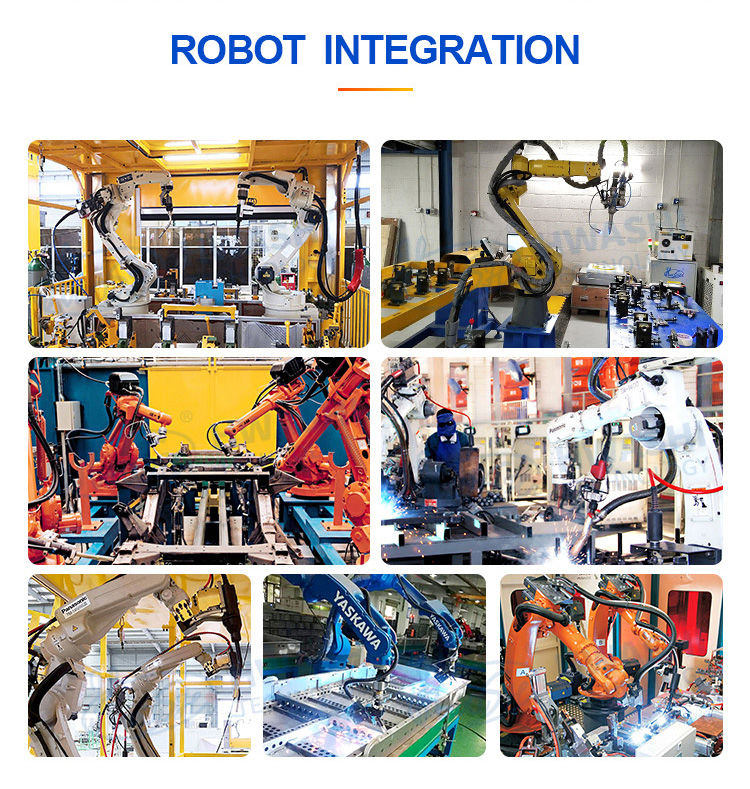

Robot Integration

In addition to HWASHI robot systems, we can also integrate with international brands of robot to provide complete welding robot solutions.

Robot Cases and Welding Samples

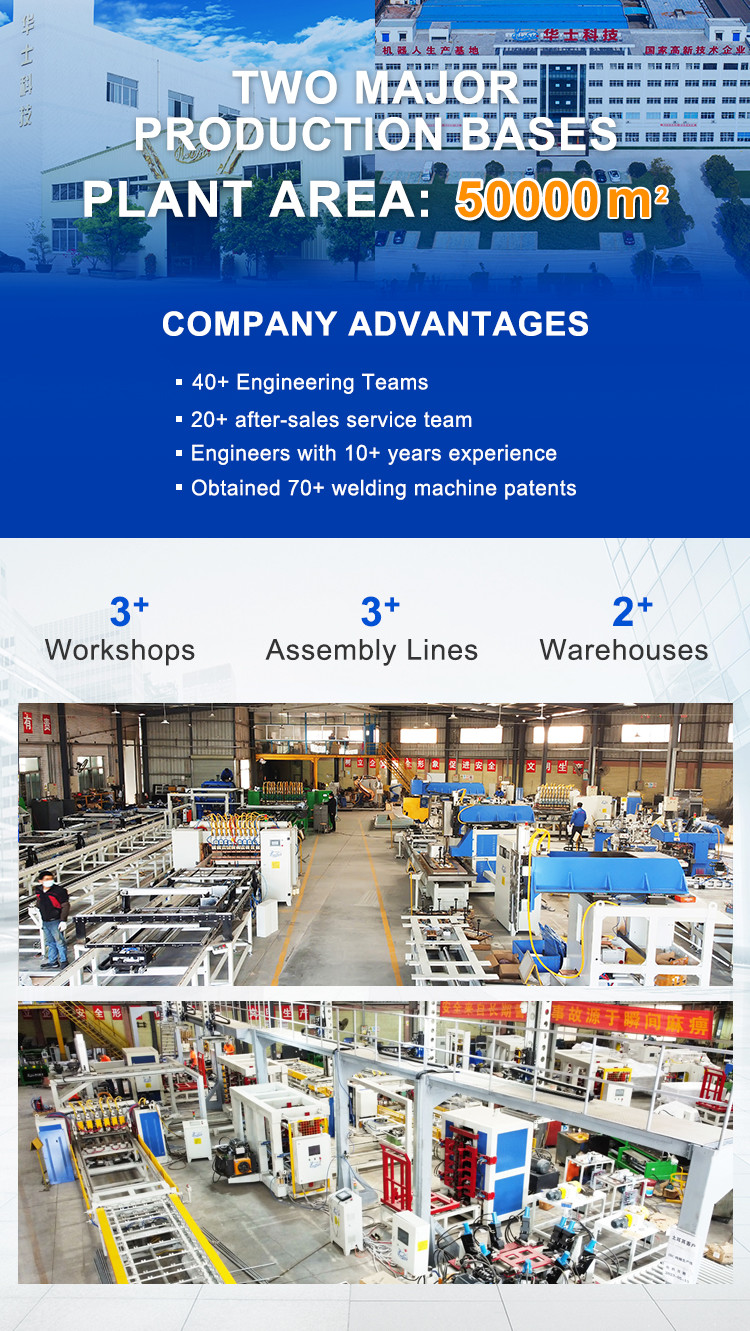

Our Company